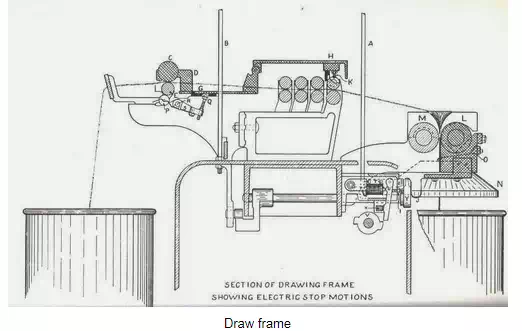

Draw Frame

This is the machine on which drafting & doubling are carried out. Carded sliver is that they are not even (uniform) enough to produce to good quality yarns. Therefore, usually all the carded slivers are subjected to Doubling & Drafting on a machine called “Draw Frame”.

Doubling is the practice of feeding two or more strands to produce one Strand. To attenuate fiber laps to slivers, Drafting is carried out. Different methods are used to draft sliver or yarn. One method is called “Roller Drafting”. During drafting the number of fibers in the cross section of the sliver or lap is reduce.

Tasks of Draw frame

Equalizing

Parallelizing

Blending

Equalizing:

One of the main tasks of draw frame is improving evenness over short, medium and especially long terms. Carded slivers are fed to the draw frame have degree on unevenness that cannot be tolerated in practice and slivers from the comber contain the “infamous” piecing. It is obscured by draw frame.

Equalizing is always performed by a first process, namely doubling and can optionally also be performed by a second process, namely auto leveling. The draft and the doubling have the same value and lie in the range of 6 to 8.

Parallelizing:

To obtain an optional value for strength in the yarn characteristics, the fibers must be arranged parallel in the fiber strand. The draw frame has the tasks of creating this parallel arrangement. It fulfills the task by way of the draft, since every drafting step leads to straightening the fibers.

Blending:

In addition to the equalizing effect, doubling also provides a degree of compensation of raw material variation by blending. Their results are exploited in particular way in the production of blended yarns comprising cotton or synthetic blends. At the draw frame metering of the individual components can be carried out very simply be selection of the number of slivers entering the machines.