Vulcanisation & Reinforcement

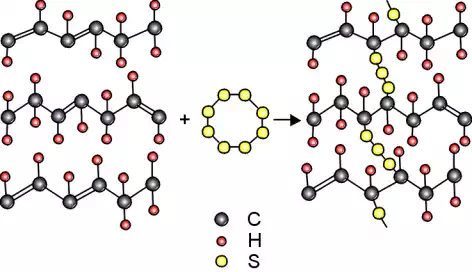

Vulcanisation

Vulcanisation is the process by which a chemical is added to induce the formation of cross-links between molecular chains. The process provides a stronger and more durable rubber that is far more resistant to chemical attack.

The most common vulcanising agent is sulphur, however, other peroxide-based systems may also be used.

The invention of vulcanised rubber has revolutionised the industrial world. Today, it is used in many important fundamental applications from car tyres to seals and tubes for high pressure machinery.

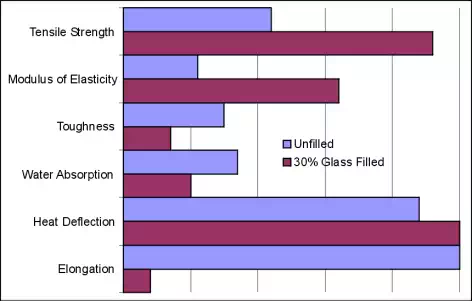

Fibre Reinforcement

One of the most common methods to increase the strength and elastic modulus of a polymer is to reinforce it with fibres of a stronger and stiffer material.

This produces a composite material where the main strength and rigidity is derived from the presence of the fibres.

The polymer acts as a means of transferring load between the fibres and protecting them from abrasion or corrosive damage, while also providing some flexibility to the material.