History of Antimicrobial Finish

During world war II, when cotton fabric was extensively used for tent age,

tarpaulins and truck covers, these fabrics need to be protected from rotting caused

by microbial attack. This was particularly a problem in the south pacific

campaigns, where much of the fighting took place under jungle like conditions.

During the early 1940’s, the US army quartermaster Crops and collected and

complied data on fungi, yeast and algae isolated from textiles in topical and

subtropical areas throughout the world (Lee , Hwang & Kim, 2009).

Cotton duck, webbing and other military fabrics were treated with mixtures

of chlorinated waxes, copper and antimony salts that stiffened the fabrics and

gave them a distinct odor. At the time potential polluting effects of the

application

materials and toxicity related issue were not a major consideration. After

world war II, and as late as the mid-to-late 1950’s fungicides used to cotton

fabrics were compounds such as 8-hydroxyginoline salts, copper napthenate,

copper ammonium fluoride and chlorinated phenols. As the government and

industrial firms became more aware of the environment and workplace hazards

these compounds caused. Alternative products were sought.

Microbial growth on textile leads to odor development, mildew growth derived

discoloration up to the loss of functional properties (elasticity and tenacity)

For that reason already in the seventeenth century ship cloth was conserved by

tanning with iron salt solutions (Brown color) . The use of hygienically

effective substance today is related to body tight worn garment and sports

textiles, mattresses and socks. Especially cellulosic fibers are in the first

place cotton are targeted fibers for antimicrobial functionalization.

Microbes:

A microorganism or microbe is a microscopic living organism, which may be

single- celled or multicellular Microorganisms i.e. bacteria, fungi, mildew,

mold and yeasts are found everywhere in nature, even in hostile environment.

The human is usually crowded with innumerablemicroorganisms. A suitable

temperature, moisture, dust and receptive surface provide perfect conditions

for their growth .In favorable conditions certain bacteria can grow from a

single germ to millions in a very short period of time. They can double every

20-30 seconds in a warm and mosit microclimate that has plenty of food for them

e.g. perspiration and other body secretions, skin particles, fats and left

overs from worn-out threads

Type of microbes that attack

textile materials

Microbes are the tiniest creatures not seen by the naked eyes. They include a

variety of micro-organisms like bacteria, fungi, algae and virus. Further, subdivisions

in the bacteria family are Gram positive (staphylococcus aurous), Gram negative

(E-coli), Spore bearing or non-spore bearing type. Some specific types of

bacterial are pathogenic and cause cross infection. Fungi, molds or mildew are

complex organisms with slow growth rate. They are part of our everyday live and

found everywhere in the environment and on our bodies.

Attack of Textile Materials

by Microbes

Natural Fibers

Textiles made from natural fibers are generally more susceptible to

biodeterioration than are the synthetic (man-made) fibres. This is because

their porous hydrophilic structure retains water, oxygen and nutrients,

providing perfect environments for bacterial growth. Products such as starch, protein

derivatives, fats and oils used in finishing of textiles can also promote

microbial growth. Micro-organisms may attack the entire substrate, that is the

textiles fibres or may attack only one components of the substrate, such as

plasticizer contained therein, or grow on dirt that has accumulated on the

surface of a product. Nevertheless, even mild surface growth can make a fabric

look unattractive by the appearance of unwanted pigmentation. Heavy infestation

which results in rotting and breakdown of the fibres and subsequent physical

changes such as loss of strength or flexibility may cause the fabric to fail in

service.

Materials by microbes

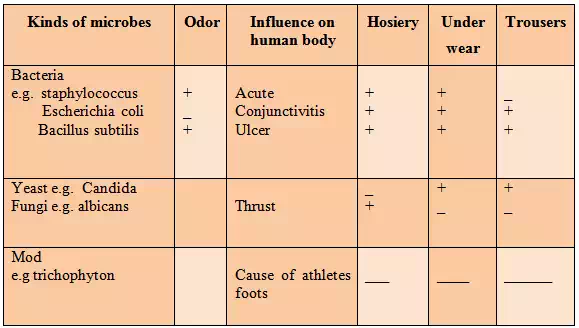

People are totally concern over the problems of odour, staining, deterioration,

and human health condition such as allergies or infectious disease (Tables 1)

Table 1: Some of common microbes and their influence

|

|

Application of antimicrobials by leaching technology:

The vast majority of antimicrobials work by leaching or moving from the surface

on which they are applied. This is the mechanisms used by leaching

antimicrobials to poison a microorganism. Such chemicals have been used for

decades in agricultural application with mixed results. Besides affecting

durability and useful life, leaching technologies have potential to cause a

variety of other problems when used in garments. These include their negative

effects because; they can contact the skin and potentially affect the normal

skin bacteria, cross the skin barrier, and/or have the potential to cause

rashes and other skin irritations.

Effects of microbes on textile and human beings:

Although microbes can be useful in many ways, for example in brewing, baking and

biotechnology, they can also be harmful to both textile and humans. Different

substances added to textiles, such as size, hand modifiers, antis tats,

thickeners, lubricants and dirt as well as grease, sweat and dead skin from the

human body provide a great source of nourishment for microorganisms. Following

are some of the possible effects microorganisms on textiles;

§ Bad odor

§ Discoloration

§ A slick slimy handle

§ Loss of functional properties like elasticity and tensile strength

§ Decrease in the life of the textiles, especially cotton and wool

The effect on human health is

much more vast than the effect on textile. Most of the microbes involve

diseases. Some of them do cause the prevention of some diseases. Bacteria

associated with the human body outnumber body cells by ten to one. In most

causes the bacteria that cause sickness are that bacteria that normally inhibit

the body. They are picked up from the atmosphere. Some of the effect that are

caused by microbes on human being is pointed out below : Various types of

infectious diseases such as plague, tuberculosis, anthrax, malaria etc.

§ Food poisoning and water caused diseases

§ Damage of building materials

§ Bad odor

Antimicrobial component:

Normal home-washing of textiles, which is generally under mild conditions, does

not completely remove the microbes. In order to eliminate microbes, very severe

laundering conditions, e.g. a temperature 95°c and strong detergent followed by

bleach, are essential. Any surviving microbes can quickly multiply again at

each further wearing. This can be avoided by the application of antimicrobial

(Mahesh, Manjunatha Reddy, & VijayaKumar, 2011).

In this research chitosan is used as antimicrobial agent. This have been

investigated as an antimicrobial material against a wide range of target

organism like algae, bacteria, yeasts and fungi in experiments involving invivo

and in vitro interactions with chitosan in different forms ( solution, film and

composites ). Chitosan is considered to be a bactericidal ( kills the live

bacteria or some fraction) or bacteriostatic ( hinders the growth of bacteria

but does not imply whether or not bacteria are killed), often with no

distinction between activities. The exact mechanism is not fully understood and

several other factors may contribute to the antimicrobial action (Lourenço et.

al., 2013).

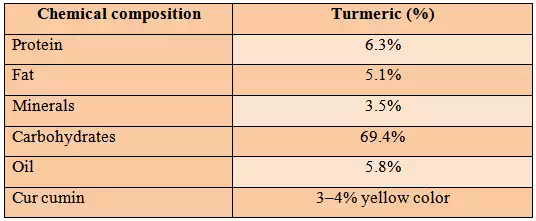

Chemical composition of turmeric:

|

|

|

Table 2.2: Chemical composition of turmeric |

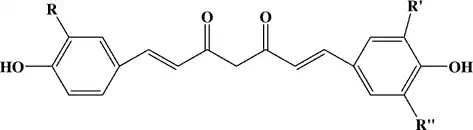

Chemical structure of turmeric extracts compound and curcumin

|

|

|

Figure 2.1: Structure of turmeric extracts |

R' =R''= H: Curcumin

R = OMe; R´=H; R''=H: Demethoxycurcumin

R = R'= R''=H:Bis-demethoxycurcumin

R =OMe; R'= OH;R''= H:(1E,6E)-1-(4-Hydroxy-3-methoxyphe-

nyl)-7-(3,4-ihydroxyphenyl)-1,6-heptadiene-3,5-dione

R = R'= R''=OMe:5'-MethoxycurcuminAntibacterialpropertiesoftreated

Required for an

antibacterial agent:

Textile material in particular, the garments are more susceptible to wear and

tear. It is important to take into account the impact of stress strain, thermal

and mechanical effects on the finished substrates. The following requirements

need to be satisfied to obtain maximum benefits out of the finish. Durability

to washing, dry cleaning and hot pressing. Selective activity to undesirable

microorganisms. Should not produce harmful effects to the manufacturer, user

and the environment. Should comply with the statutory requirements of

regulating agencies (Mandroli & Bhat, 2013).

Compatibility with the chemical processes. Easy method of application.No

deterioration of fabric quality Resistant to body fluids.Resistant to

disinfections/ sterilization.

Safety, non-toxicity for human health and the environment and also

biodegradability are required for an antibacterial agent.

Durability of Antimicrobial

Textiles

Temporary antimicrobial properties in textiles are easy to achieve in finishing

but readily lost in laundering. Temporary antimicrobial textiles are useful

only for disposal materials. Durable antimicrobial function is quite

challenging to achieve and can last more than 50 machine washes (Murthy,

Soumya, & Srinivas, 2015).

Mechanisms of antimicrobial

finishes:

Despite the long list of requirements, a variety of chemical finishes have been

used to produce textiles with demonstrable antimicrobial properties. These

products can be divided into two types based on the mode of attack on microbes.

One type consists of chemicals that can be considered to operate by a

controlled-release mechanism. The antimicrobial is slowly released from a

reservoir either on the fabric surface or in the interior of the fibre. This

‘leaching’ type of antimicrobial can be very effective against microbes on the

fibre surface or in the surrounding environment (Naz, et. al., 2010). However,

eventually the reservoir will be depleted and the finish will no longer be

effective. In addition, the antimicrobial that is released to the environment

may interfere with other desirable microbes, such as those present in waste

treatment facilities. The second type of antimicrobial finish consists of

molecules that are chemically bound to fiber surfaces. These products can

control only those microbes that are present on the fiber surface, not in the

surrounding environment. ‘Bound’ antimicrobials, because of their attachment to

the fiber, can potentially be abraded away or become deactivated and lose long

term durability. Antimicrobial finishes that control the growth and spread of

microbes are more properly called biostats, i.e. bacteriostats, fungi stats.

Products that actually kill microbes are biocides, i.e. bacteriocides,

fungicides. This distinction is important when dealing with governmental

regulations, since biocides are strongly controlled (Rachana, S., &

Venugopalan, P. (2014).

Antimicrobial effects:

Turmeric extract and the essential oil of Curcuma longa (turmeric) inhibit the

growth of a variety of bacteria, parasites, and pathogenic fungi. A study of

chicks infected with the caecal parasite Eimera maxima demonstrated that diets

supplemented with 1-percent turmeric resulted in a reduction in small

intestinal lesion scores and improved weight gain. Another animal study, in

which guinea pigs were infected with either dermatophytes, pathogenic molds, or

yeast, found that topically applied turmeric oil inhibiteddermatophytes and

pathogenic fungi, but neither curcumin nor turmeric oil affected the yeast

isolates. Improvements in lesions were observed in the dermatophytes and

fungi-infected guinea pigs, and at seven days post-turmeric application the

lesions disappeared. Curcumin has also been found to have moderate activity

against Plasmodium falciparum and Leishmania major organisms (Singh & Jain,

2011).

Chitosan:

Chitosan is a deacetylated derivate of chitin, which is a natural

polysaccharide mainly derived from the shells of shrimps. Chemically, it can be

designated as poly-β-(1→4)-D-glucosamine or poly-(1,4)-

2-amido-deoxy-β-D-glucose (Tiwari, et. al., 2009). In addition to its

antimicrobial activity, chitosan has some important advantages such as

non-toxicity, biocompatibility and biodegradability (Lertsutthiwong &

Rojsitthisak, 2011).

The antimicrobial efficiency of chitosan depends on its average molecular

weight, degree of deacetylation and the ratio between protonated and

unprotonated amino groups in the structure It is believed that chitosan of a

low molecular weight is more antimicrobially active than chitosan oligomers.

The efficiency also increases with increased deacetylation, which can exceed

90%. An important disadvantage of chitosan is its weak adhesion to cellulose

fibers, resulting in a gradual leaching from the fiber surface with repetitive

washing. To enable chitosan to bind strongly to cellulose fibers, various

crosslinking agents are used, including mostly polycarboxylicacids . In the

presence of a crosslinking agent, hydroxyl groups of chitosan and cellulose can

form covalent bonds with carboxyl groups of polycarboxylic acid in an

esterification reaction or with hydroxyl groups of imidazolidinone in an

etherification reaction, thus leading to the formation of a crosslink between

chitosan and cellulose. This greatly improves durability and wash resistance (Ungphaiboon,

et. al., 2005).

Benefit of antimicrobial

textiles:

A wide range textile product is now a available for the benefit of the

consumer. Initially, the primary objective of the finish was to protect

textiles from being affected by microbes particularly fungi. Uniforms, tents,

defense textile and technical textiles, such as, geo-textiles have therefore

all been finished using antimicrobial agents. Later, the home textiles, such

as, curtains coverings and bath mats came with antimicrobial finish. The

application of the finish is now extended to textile used for outdoor, health

care sector, sports and leisure (Zemljic, et. al., 2014).