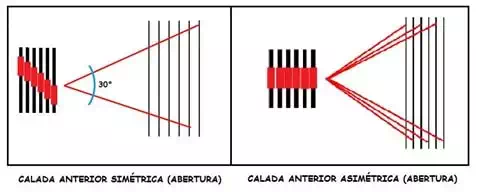

The Anterior Shed:

The separation of yarns formed between the beat-up and the needle (frame) is

called "anterior shed". As an initial basic adjustment, you should

seek for the smallest possible shed angle, sufficient for a clean weft insertion.

For an adjustment it will be necessary to control the shed from the beginning

of the insertion to the end of it, being at 180° after the crossing of the shed

a maximum position that will show us the appearance or formation of the shed.

There are two types of anterior shed:

Anterior shed symmetrical: The yarns of the upper shed and of the lower

shed form closed lines. To form a shed symmetrical angle the opening of the

frames is increasing, therefore they have different tensions.

Applications:

· Filament fabrics, warp with little hairiness.

· Lightweight fabrics easily separated warp.

· Fabrics with a low density of warp.

Anterior shed asymmetrical: The yarns of the upper shed and / or the

lower shed form different layers (different lines)

Applications:

· Fabrics with warp hairiness difficult to separate.

· Fabrics with a high density of warp per comb tooth.

Is possible to regulate

different variants of shed asymmetric:

1. With shed height:

Used in basic fabrics (taffeta, twill, satin) to separate in different

layers.

Example:

• In ligaments with four frames

1st frame = basic adjustment+ 0 mm

2nd frame = basic adjustment + 1 mm or 2mm

3rd frame = basic adjustment + 2 mm or 4mm

4th frame = basic adjustment + 3 mm or 6mm

• Taffeta of four frames

1st frame = basic setting

2nd frame = basic setting

3rd frame = basic adjustment + 2 mm or 4mm

4th frame = basic adjustment + 2 mm or 4mm

2. With shed angle (opening):

Used in special fabrics that combine ligaments with different elongation

points, it consists of giving different angles according to the ligament.

Example:

The frames that correspond to the twill that has more elongation should be

given less opening than the frames that correspond to the taffeta that has less

elongation. In this way it is about compensating or equaling warp tensions;

remember that having more opening this warp stretches more and needs to recover

this elongation.

3. With shed crossing:

Used only in cam motion, mainly in articles with high warp density and

difficult separation in needle and reed, by giving different shed crossing the

pairs of frames will cross at different times, having a better separation.

Example:

Frame 1 and 2 cross to 320 °

Frame 3 and 4 cross to 310 °

Frame 5 and 6 cross to 300

|

|

It is possible to use

combinations of these three variants according to the complexity or need,

taking care that one of them does not negatively influence the other, so that

it decrease or cancel the obtained advantage.

Effects of Shed Crossing:

(reference of degrees for a loom with beat-up 0°)

1. Early Crossing: 290° - 310°

· The filling is dragged with more friction and less tension in front of the reed, this allows it to better accommodate the beat-up.

· The filling has less contraction.

· Is favorable in heavy fabrics and wavy marks problems.

· It does not favorable fabrics with hairiness yarns since having more friction creates more pilosity.

· Presents a more closed aspect of the fabric.

2. Standard Crossing: 310° -

320°

3. Delayed Crossing: 320° - 350°

· The inserted filling is dragged without creating any tension as it is softer dragged to the front beat-up.

· We take better care of the filling.

· Does not favour heavy fabrics.

· The filling loses some of its tension, favorable for weak and hairiness warp.

· It can cause vertical reed marks, rapier guides, projectile or relay nozzles.

· The fabric has greater force the beat-up.

The Posterior Shed:

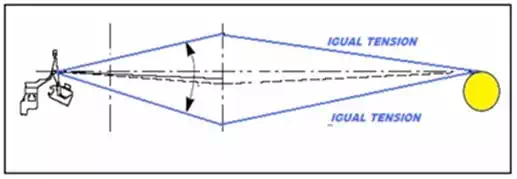

Posterior shed symmetrical: The support of the fabric in the anterior shed

is the temple profile. This forms a line with the feeler roll.

In this way a symmetric line is obtain; here the warp of the upper shed and the

lower shed have the same tension. So the warp are better taken care.

It can be used as a basic adjustment for light fabrics with low density, low

cover factor, fabrics with weak warps, with loops warp.

|

|

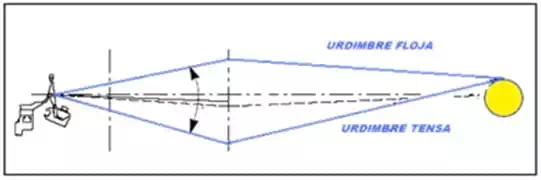

Posterior shed

asymmetrical:

Upwards: The height of the feeler roll adjusted above the point of

symmetry.

With this adjustment, the lower shed have more tension and the upper shed have

less tension. Thus, a beat-up effect is produced, higher weft densities can be

possible obtain since the filling are placed one on top of the other achieving

a more closed appearance of the fabric.

It can be used as a basic setting in heavy fabrics such as denim, canvas,

awnings, etc., as well as in poplin to improve the striped appearance of the

fabric.

When working with cam motion, it is possible to achieve this effect using

asymmetric eccentrics with the longest position down, so we do not need to give

a lot of height to the feeler roll, favouring ergonomics.

|

|

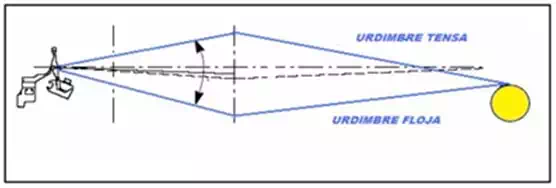

Down: The height of the feeler roll adjusted

below the point of symmetry.

With this adjustment, the upper shed have more tension and the lower shed have

less tension. It can be used in fabrics where the highest load is woven upwards

and is favorable for the best distribution and separation of the warps.

When working with cam motion, it is possible to achieve this effect using

asymmetric cams with the longest position upwards; in this way we do not need

to lower so much the height of the feeler roll.

|

|

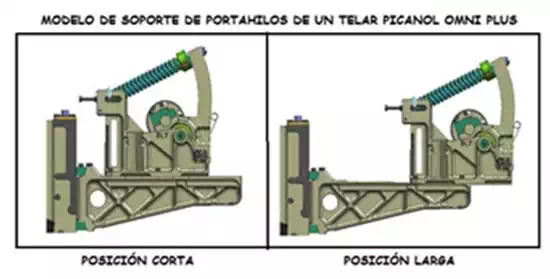

Posterior shed short:

The back rest adjusted in position as more close to frames.

In this position the warp tension is bigger because the distance is shorter; a

better separation of the warps is obtained in a way that favorable in hairiness

warps.

It can be used in heavy fabrics and up to 8 frames since more frames can cause

the action of the shed to raise the forks on their rails causing false stop

warps or damaging the rails.

Posterior shed intermediate:

The back rest adjusted in intermediate position. Is possible obtain a better

care of the warps since the distance to be controlled is greater.

It can be used as a basic adjustment in lightweight fabrics of 4 to more

frames, in weak warps and with little elongation.

Posterior shed long:

The backrest adjusted in position farthest from the frames.

With this shed is possible to compensate better the warp tensions caused by

warps with different ligaments, since the distance to be controlled is much

greater.

It can be used on fabrics with weak warps and special fabrics with different

elongation points.

|

|