Sewing Machine Needles: Types, Parts, Sizes and Applications

Sewing Machine Needle and Its Purposes:

Needle is

the central feature of any sewing machine. The manner in which fabric is

pierced by the needle during stitching has a direct impact on the strength of

the seam as well as garment appearance.

The purposes of the sewing needles are to:

§ Make a hole in the fabric so that the sewing thread could pass through it to form a stitch without causing any damage to the fabric while doing so.

§ To carry the needle thread through the fabric to form a loop. This is then taken up by the hook in a lockstitch machine or by means of the looper in chain stitch machines.

§ Pass the needle thread through the loop created by the looper mechanism on a chain stitch machine.

Parts of a Sewing Needle:

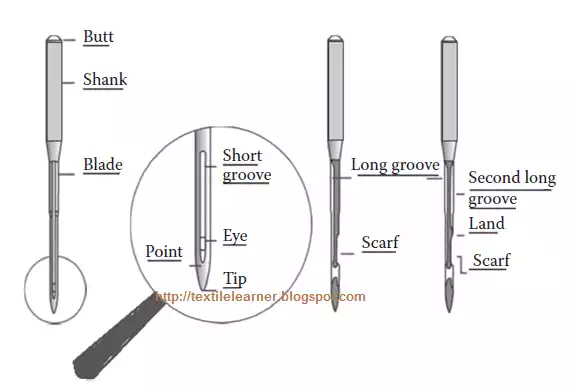

The different parts of a sewing needle are shown in Figure-1.

|

|

|

Figure-1: Parts of a sewing machine needle. |

Every parts of sewing machine needle are

described below:

Shank: It is the top portion of the needle, which positions inside the

needle bar. It could be designed as cylindrical or have a flat side, based on

the method of holding it on to the needle bar. It is the principal support of

the entire needle and is larger in diameter than the remaining part of the

needle to give the strength.

Shoulder: It is the part in-between the shank and the blade, with the

blade forming the longest portion of the needle up to the needle eye.

Blade: It undergoes an enormous amount of friction from the fabric through

which the needle passes. In case of needles specifically designed for

high-speed sewing, the shoulder is normally extended into the upper part of the

blade to give a thicker cross section. This arrangement of reinforced blade

strengthens the needle and produces the enlarged hole in the fabric while the

needle is at its lowest point, thus minimising the friction between it and the

material. On the other hand, the blade could be designed as a tapered one,

reducing its diameter gradually from shank to tip to minimise the

friction.

Long groove: It gives a shielding channel for the sewing thread while it

is carried down into the fabric for stitch formation thus reducing the abrasion

and friction with the fabric.

Short groove: It is located on the reverse side of the long groove, that is,

towards the hook or looper; it extends slightly above and below the needle eye.

It assists in the formation of the needle thread loop.

Eye: It is the hole or opening in the sewing needle, lengthened through the

blade along the long and short grooves on the needle. The profile of inside

part of the eye at the top is vital in reducing sewing thread damage

and in producing a good loop formation.

Scarf: The scarf otherwise known as clearance cut is a nook across the

whole face of the needle immediately above the needle eye. Its objective is to

facilitate closer setting of the bobbin hook or looper to the needle so that

the needle thread loop could be entered more easily by the point of the hook or

looper.

Point: It is tapering portion of the needle created to give a better

penetration of the needle on various kinds of fabric. It should be properly

selected to prevent damage of the fabric to be sewn.

Tip: It is the ultimate end of the point, which combines with the point in

defining the penetration performance of the needle.

Special Needles:

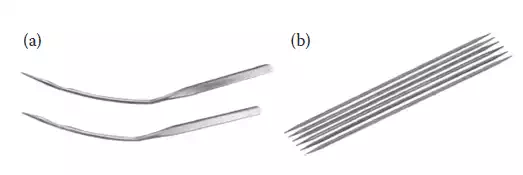

Several over-edge and safety stitch sewing machines utilize curved needles

instead of straight needles. These needles are costly though the life of the

needle is lesser compared to straight needles. However, the sewing

machines utilising curved needles (Figure-2a) could achieve higher speeds

than by using straight needles. Blind stitching machines also utilise needles

that are curved, but the purpose here is to avoid penetration right through the

fabric. Sewing machines (pick stitching machine) that imitate hand stitch

(class 209) utilise a double-pointed sewing needle with an eye in the middle

(Figure-2b), through which is threaded the short length of thread with which

this machine sews.

|

|

|

Figure-2: Special needle shapes. (a) Blind stitch needle. (b) Pick stitch needle. |

Identification of Sewing Needle:

Three parameters are generally used for the identification of sewing needles

such as system, point and size.

System:

It describes the elements of a needle to suit the sewing machine type. Based on

the type of sewing machine and type of stitch, the needle is designed with

variants in blade length, shank thickness, type of needle eye, etc. It is

worthwhile to ensure with the sewing machine manufacturer for appropriateness

of needle system to machine.

Needle Point:

A needle point is broadly categorized into two types:

1. Round point needle – set or cloth points

2. Cutting or leather point needle

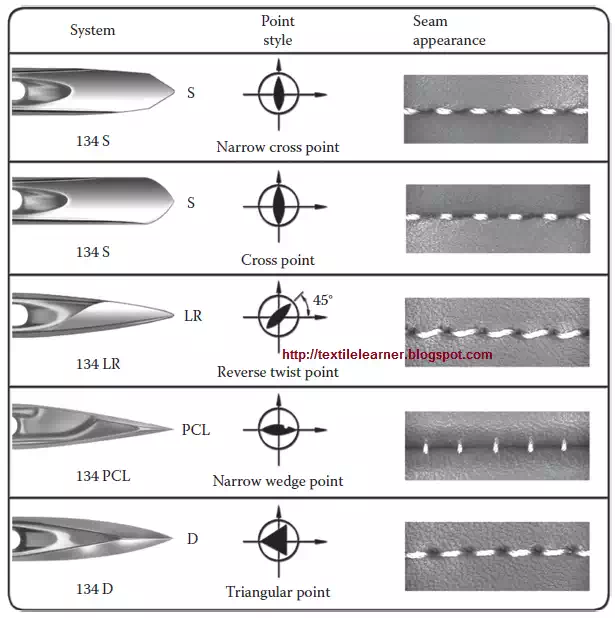

Cutting Point Needles:

Cutting point sewing needles have spiky tips like blades and a wide range of

cross-sectional profiles such as rounded, triangular, square and lens exist.

They are normally used to sew highly dense and non-fabric based materials. Five

universal kinds of cutting point sewing needles are shown in Figure-3, along

with their profile of incision produced when used in a machine with the

commonest threading direction.

|

|

|

Figure-3: Cutting point needles. |

The narrow wedge point needle: It cuts the material at right angles

(90°) to the seam direction and permits to go for a high stitch density (SPI)

while leaving adequate material between the needle holes to retain seam

strength of material. On soft leather material, stitch densities as high as 12

per centimetre are achievable. It is the most frequently utilised cutting point

needle for stitching uppers in the shoe industry.

§ The narrow reverse point needle: It produces cut that lies 45° to the seam direction, and produces a seam where the thread is turned to the left on the surface of the material.

§ The narrow cross point needle: It makes a cut along the line of the seam and necessitates a longer stitch length. Heavy decorative seams could be made where thicker sewing threads are used at lower stitch densities, that is, longer stitch length.

Numerous kinds of other point types exist for the variety of leathers,

seams, sewing machines and strength and appearance requirements that arise.

This involves triangular cross sections for multi-directional sewing.

Cloth Point Needles:

These kinds of needles are used for sewing textile materials instead of the leather/sheet

materials as in the case of cutting point needles. The points have a round

cross section contrasting to the various cutting profiles of the cutting point

needles and the tip at the end of the point can vary in profile to suit the

particular material being sewn.

§ The contour of the tip of the needle point which attains the deflection rather than penetration is a fine ball shape and the needle is called a light ball point needle which is utilised primarily for sewing knitted fabrics.

§ The tip of the needle point which attains the penetration has the shape of a cone and is known as a set point needle which is utilised for sewing woven fabrics. Both ball and set point needles are available in a number of types, illustrated in Figure-4.

|

|

|

Figure-4: Types of cloth point needles. R: set cloth point, SPI: slim set point, SES: light ball point, SUK: medium ball point, SKF: heavy ball point, SKL: special ball point. |

Slim set point (SPI): It

is generally used for sewing denser woven fabrics and aids in achieving a

straighter stitch which could minimise seam pucker. Generally used for heavy

woven fabrics, coated fabrics and topstitching of collars and cuffs.

Medium set point needle: It is the general purpose needle in no problem

sewing situations. It is commonly used for sewing a range of woven fabrics and

in many circumstances could be used for knitted fabrics also.

Set cloth point (R): It is generally utilized for sewing standard fabrics

with regular seams.

Acute set point: This kind of needle is used while sewing very dense

fabrics like shirting fabric and interlining in collars and cuffs, where a

straight line of stitching is required.

Heavy set point: These needles are used for sewing buttons as the button

can be deflected to some extent into the correct position; thus, the needle can

pass through the holes.

Light ball point (SES): It can be used for sewing lightweight knitted

fabric and densely woven material.

Medium ball point (SUK): It is utilised for sewing denim fabrics of medium

to coarser weight and knits.

Heavy ball point (SKF): It is utilised for sewing heavier woven elastic

materials as well as coarser knits.

Special ball point (SKL): It could be utilised for sewing heavy knits and

coarse elastics.

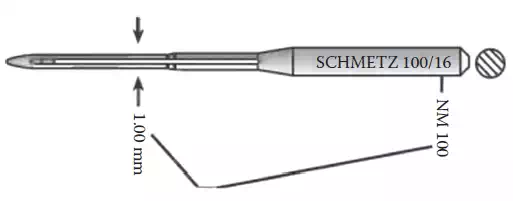

Needle Size:

The needle size is normally expressed in two ways. One of the basic methods of

representation is by a metric number (Nm). This system represents the diameter

of the needle blade in hundredths of a millimetre measured just above the scarf

area. For example, a needle size of Nm 100 is 1.0 millimetre in diameter as

shown in Figure-5. Another standard needle sizing method is the Singer system,

otherwise called the American system, which uses a number that represents a

size.

|

|

|

Figure-5: Metric needle sizing. |

Needles are offered in a wide range of sizes and the selection of needle

size is based on the combination of fabric and sewing thread which is to be

sewn. If the selected sewing needle is too small for the sewing thread size,

the thread will not fit well into the long groove of the needle and will suffer

from extreme abrasion. The use of too fine a needle while sewing heavy plies of

fabric could lead to the deflection of the needle, which could influence the

stitch loop pick up and cause slipped stitches or even needle breakage. Use of

a larger sewing needle for the particular sewing thread resulted in poor

control of the loop formation which could lead to slipped stitches.

Application of Sewing Machine Needles:

General purpose needles:

The general purpose needles used in apparel

manufacturing are given in Table-1.

Table-1: Application of General Purpose Needles

|

Needle |

Description |

Fabric |

Sizes |

|

Ball-point |

It has a medium tip, rounded compared to universal needle |

Knits |

70/10 – 100/16 |

|

Sharp |

It has a slim shaft and sharper needle point |

Fine woven fabrics |

60/8 – 90/14 |

|

Universal |

Needle point is marginally rounded; however, it is sharp enough to pierce woven fabrics |

Woven and knitted fabrics |

60/8 – 120/19 |

Specialty needles:

The specialty needles used in garment manufacturing are given in Table-2.

Table-2: Application of Specialty Needles

|

Needle |

Description |

Fabric |

Sizes |

|

Denim |

It has a thicker and stronger shaft and a sharp needle point |

Denim and heavy woven fabrics |

70/10 – 110/18 |

|

Leather |

It has a wedge-shaped needle point |

Leather and nonwoven fabrics |

80/12 – 110/18 |

|

Machine embroidery |

It has a larger eye and a special scarf to protect the sewing thread |

For embroidery |

70/10 – 90/14 |

|

Metallic |

It has a larger eye than the embroidery needle, and a sharp point to avoid thread breakage |

For metallic threads |

80/12 |

|

Quilting |

It has a tapered as well as sharp needle point |

Machine quilting |

75/11 and 90/14 |

|

Spring needle |

It has a shaft surrounded by the wire coil, which acts as a presser foot |

Quilting |

|

|

Stretch needle |

It has a deep scarf to avoid skipped stitches |

Lightweight knitted fabrics |

75/11 and 90/14 |

|

Topstitch needle |

It has an extra-large eye and a large groove |

Topstitching |

80/12, 90/14 and 100/16 |

|

Twin needle |

It is constructed with two needles attached to a single shaft |

Double topstitching |

1.6/70 – 4.0/100 |

|

Triple needle |

It is constructed with three needles attached to a single shaft |

Triple topstitching |

2.5/80 and 3.0/80 |

|

Hemstitch needle |

It has a widened shaft and produces a decorative hole in tightly woven fabrics |

Decorative stitching |

100/16 and 120/19 |

Surface Finishing of Sewing

Needles:

Sewing needles are normally made from steel and during their final

manufacturing stage they are polished, specifically in the needle eye area.

They are then electroplated using chromium or nickel to provide resistance to

mechanical wear, corrosion resistance and reduction of friction during sewing.

One of the main requirements of the surface finishing of needles is it should

not pick up any elements of synthetic fabric or thread which could melt due to

excessive heat generation. By considering this aspect, the chromium-plated

sewing needles are superior compared to nickel-plated needles.