Basic Controls

Is necessary to ensure the correct state and operation of the mechanical and

electronic parts of the loom to rule out possible open and / or dense by

default of machine, for example:

1. Mechanical function of let-off and take-up

· Bearings

· Gears

· Transmission chains

· Supports / joints

· Covering of sand beam and pressure rollers.

2. Temple, wear and type of

rings according to the fabric.

3. levers: transmission of the shed former, wastage of the bearings

4. Drive and brake of machine, pulleys and transmission belts.

There is also the possibility that the fabric presents open or dense defects

during the weaving process, but these are attributed to defects of some

mechanical or electronic component. This report will not review these defects,

which correspond to preventive and / or corrective maintenance.

Main Causes:

We will review three main causes that generate the stops marks and starting

marks and that in modern looms we have the option to control and

regulate.

Machine stop times:

The start marks are more notorious depending on

the time that the loom is stopped waiting for its intervention, the longer the

stoppage, more severe is the failure; this reason is basically a work method.

It must be sought to reduce machine stop as much as possible; with textile

adjustments to avoid machine stop or with timely attention; For example, if

there is a warp stop on a loom and a filling stop on another loom, the filling

stop should be repair first since it is faster to intervene and repair next the

warp stop.

Nominal speed:

It is the adjusted maximum speed of a loom

during its working process and it differs according to the load or the slow

motions of the loom. Here it is important to understand three concepts:

Braking angle: When a machine stop occurs, it does not stop

instantly; it has a brake slip depending on the type of drive or the machine

speed. This can be from 40 ° to approximately 200 °. It is important to know

this information, since it allows us to know how the last picks inserted pass

was completed. If this last was during the beat-up moment, it is possible that

a open mark is generated; since it will be less than its nominal speed (less

force beat-up).

Stop position: After the machine stop has been produced, it is

positioned in a specific adjusted degree. The conditions of the position of

stopped will depend on the type of insertion of the loom, the ligament and the

stopped type; for example, it is recommended, when working a fabric plain, to

regulate the stop position at the moment of the shed crossing when a filling

stop occurs to avoid stretching the warp during the stop time, until the

operator arrives to look for the correct picks and start the loom; similarly

when a warp break occurs, adjust a stop position that allows the operator to

easily insert the warp through the needles and the reed without the need for

additional manual movements.

Start position: After the operator makes the repair or correction

of the stop, the machine goes to a starting position degree. The criterion here

is to seek that the first inserted picks is beat-up as close to its nominal

speed, depending on the machine rpm, the nominal speed is reached only at the

third or fourth picks. For example, when the first inserted pick leaves a open

mark at the start, what we have to regulate is the position farthest from the

finishing point; So we give you more time to reach your nominal speed.

In some modern looms, for example the Picanol loom, is possible to have the

option of regulating empty picks (ASO value), in this way, it is possible to

achieve that the first inserted picks is beat-up at its nominal speed.

It also has other electronic options to correct stop o starting marks with

adjustments in the let-off and take-up system.

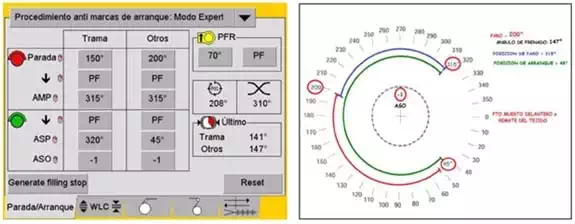

In the following image we show an interactive screen for adjusting the start

and stop marks of a PicanolOmniPlus 800 loom and on the scale how movements are

generated according to the setting made for "others

|

|

Warp tension difference:

The difference in tension that affects the stop

and start marks is determined by the correct adjustment of the shed. The shed

is the tunnel that is formed with the movement of the warps that go up and down

according to the design of the fabric through which the weft is inserted and

that we will detail some types of adjustments later on.

To regulate a correct shed it is necessary to know some conditions of the style

or fabric:

The cover factor: It is a value that indicates the covering property

of a fabric, the maximum capacity of warp or weft in a specific space. This

will help us determine if the fabric to be worked is a heavy item (> 85%

tupidity) or light weight (<65% tupidity) and in this way regulate the

appropriate posterior shed.

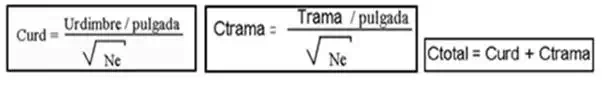

The following are the formulas for calculating the warp, weft, and total

coverage factor.

|

|

For example, if we have a

fabric with a weave plain (1/1) with a total cover factor of 31.5, with the

maximum cover for 37, then we say 31.5 / 37 is equal to 85% of tupidity; This

fabric can be considered heavy style.

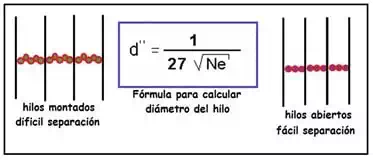

The warp density: It is important to know the amount of warp per reed,

if the style has 2 warps per tooth, 3 warps per tooth or more. Also, it is

important to know the number of teeth per centimeter. This information will

help us to know with what ease or difficulty the warp will crossing in their

movement to form the shed. This will help us to regulate the previous shed

appropriate to the weave or fabrics.

|

|

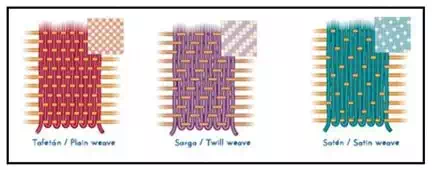

Weave of fabric: Knowing if the fabric is plain, twill, satin or dobby; also if it is a light, heavy or neutral weave will help us to regulate the appropriate posterior shed.

|

|

In addition, the

shed must have certain important basic characteristics to achieve a "clean"

shed that allows a correct separation and movement of the warp and a correct

insertion of the weft.

Shed angle: You should start working with the lowest possible

opening angle to prevent stretching the warp so much. It must be understood

that the more shed opening is regulated; it will require more time to recover

the elongation that suffers during the movement of the frames and the movements

of slow motion during the stop and start of the machine.

Shed height: It will be restricted or limited according to the type

of insertion (air, rapier or projectile). Similarly, what is sought is that

during the beat-up of the weft is made as soft as possible. Also, to help warp

layers can be individualized and to help separate them easily.

Symmetry: Depending the ligament and the cover factor, different

variants of sheds can be adjusted to allow the best work (efficiency) and the

lowest incidence of stop marks and / or starting marks (quality).

Gap: Depending the warp density, that is, the ease or difficulty of

the warp to separate from each other during the shedding movement, different

degrees of gap can be adjusted to help the warp pairs cross at different times

allowing a better separation, the best gap frame is achieved in cam motion shed

former, because makes the separation at the crossing shed moment.

Tension: According to the yarn title, the type of material, the

amount of yarns, the preparation conditions, among other factors, the

appropriate warp tension must be adjusted.