Modern Drafting System of Lap Former

Introduction

Lap former is a must needed machine for producing lap in spinning section

of textile sector. Lap former machine is used for the preparation of lap. It is

used after completing the process of blow room. Each lap former machine

contains some features which has mentioned in this article with its necessity

in yarn manufacturing technology.

|

|

|

Fig: Modern lap former machine (E35 OMEGA lap) |

The lap former has,

furthermore, the task of forming the interfacing or lap, which is employed to

feed the combing machine. The lap is obtained by doubling a certain number of

slivers (from16 to 32) previously subject to a drawing passage. The slivers are

fed side by side, passing, through rollers and stop motion. The slivers enter

the drafting section and then calendar section to produce a compact lap.

Finally the lap is wound on to bobbin. In the lap former, the material under

goes a light draft of around 1.5 to 2 times one a drawing aggregate of the type

2 on top of 3 cylinders.

There are some modern lap former introduced by Reiter & Trutchzler like:

1. Unilap

2. OMEGA lap.

Objective of this study:

· To know the feature of modern lap former.

· To know about the lap former.

· To know about the modern drafting system of lap former.

· To know about the technological data of lap former.

Apparatus:

· E35 OMEGA lap

Description:

Objective of lap former:

1. To reduce the strain to delicate comber reduce.

2. To reduce fiber damage.

3. To reduce chance of good fibers waste.

4. To reduce short fibers.

5. To reduce thick and thin places in the sliver.

6. To control wastage.

7. To parallel and straight of fiber.

8. Not freely opening of fiber from sliver

Technical Data:

Technological data of: E 36

1. Application range : 1 1/16 - 1 1/2

2. Sliver count range : 3 - 6 k tex

3. Doubling max. : 28 fold

4. Draft : 1.4 - 2.4

5. Batt weight delivery max. : 80 g/m

6. Delivery speed (constant) : 230 m/min

7. Production over : 600 kg/h

8. Lap width : 300 mm

9. Lap weight max. : 25 kg

10. Drafting system : 3 over 3 (cylinder drafting system)

Features of modern lap former:

1. Auto doffing system.

2. Auto stop motion at sliver breakage.

3. Auto grain adjuster.

4. Auto leveling.

5. Auto lap carrying device.

6. Indicator light for faulty location.

7. Lap length measuring unit.

8. Belt drafting system i.e. OMEGA lap

Drafting System:

OMEGA lap E 35 with proven winding belt technology is the most economic combing

preparation system and provides the qualitatively best conditions for

high-performance combing. Lap production is based on the unique winding belt

technology. The belt specially developed for this purpose is wrapped around the

lap as it builds up. This results in an optimal distribution of contact

pressure over the circumference of the lap. This enables production of a

uniformly wound lap of optimal quality, at simultaneous maximum productivity

and speed.

Components of OMEGA lap:

The E 35 OMEGA lap consists of in feed, winding head and delivery sections.

1. The in feed section comprises the creel, arranged centrally, the web table with the 2 drafting units, positioned linearly and without deflection plates, and web doubling toward the winding head.

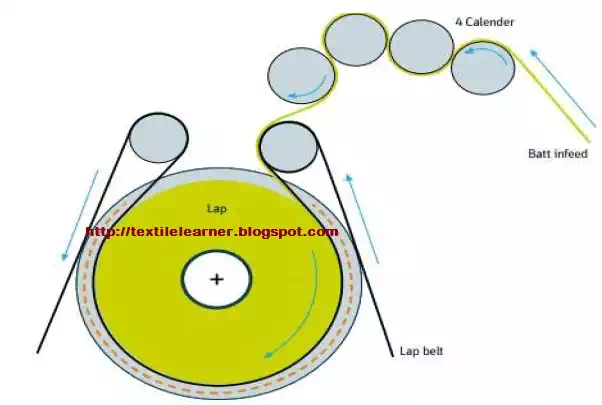

2. The winding head accommodates the drive, 4 calendar rolls and the belt winding and tensioning system.

3. At the customer‘s option, the delivery section can be supplied for semiautomatic or fully automated lap transport.

4. Draw frame slivers are fed from cans to the OMEGA lap. The material is fed via sliver preserving guide elements to the 2 drafting units, where 2 webs are formed.

5. The webs are laid one on top of the other on the web table and fed to the winding head. The material passes between the 4 calendar rolls, which compress the web into a uniform batt. Studies have shown that 4 calendar rolls produce better technological results than systems using 3 rolls.

6. The batt is wound onto a tube by means of belt technology. The full lap is then ejected from the winding head and placed on a lap trolley or lap conveyor belt.

Operating Principle of the Belt System of Drafting zone:

Production of laps by means of the belt drive and tensioning system is fully

automated.

1. The empty tube is inserted; the two winding discs are closed pneumatically to secure the tube axially in position.

2. The belt unit is closed, the belt is tensioned, and the fiber fleece is fixed pneumatically in position on the tube, the winding-up process starts.

3. The batt is wound up at constant speed until full lap diameter is reached.

4. The machine is stopped, the belt unit is opened, full lap is ejected toward the front.

|

|

|

Fig: Drafting system of E35 OMEGA lap |

Advantages:

1. Gentle web guidance from beginning to end of the lap

2. Uniform pressure distribution over up to 75% of the lap circumference

3. Very high batt uniformity and superior lap quality

4. Constant winding speed of 180 m/min, regardless of staple length and lap diameter

5. Effective output of up to 520 kg/h

6. Low energy consumption per kg of yarn

Conclusion:

Lap former is used to wind lap or batt by reducing some wastage & short

fiber in better oriented formation of the fiber. Previously some conventional

method was used which has been replaced by the modern belt system drafting

method of lap former like OMEGA lap, which is more productive & economical.