How to Calculate Roving Hank and Its CV%

Introduction:

A roving is a long and narrow bundle of fiber. Rovingís are produced during the

process of making spun yarn from wool fleece, raw cotton, or other

fibers. Their main use is as fiber prepared for spinning, but they may also be

used for specialized kinds of knitting or other textile arts. Roving count

is determined as number of hanks of 840 yards present in 1 lb.

Sliver Hank = Length of hanks of 840 yards / weight in 1 lbs

The coefficient of variation is reported as a percentage and calculated from

the average and standard deviation as follows:

Standard Deviation◊100

---------------------------------------

Average

Objectives of this study:

1. To determine the hank of Sliver.

2. To determine the hank of Roving.

3. To know the sliver and Roving sample thickness.

4. To determine the relation between count and weight of Sliver and Roving.

Theory:

At first, we have to determine the count of Sliver and Roving is

compounded between beam and wrap block. Generally the beam has 1 lb length of

Sliver or Roving. So that the revolution to beam will pass 1 yards of Sliver or

Roving.

Machine description:

There is a block Roller of the Front side of the

m/c. The top side the tension is arranged .There is a count meter behind the

machine. The Sliver or Roving is passed between block roller and tension

roller.

Required

apparatus:

1. Wrap block

2. Electric balance

3. Sliver or Roving

Experimental procedure:

At first we fixed the count zero. Then the sliver is passed through the block

roller. Take yards of sliver and weight it and then determine the sliver hank.

Letís take 5 times for average hank. We also measure the standard deviation and

co-efficient of variable. Similarly measure roving hank length 6 yards also

determine CV%.

Experimental

Data:

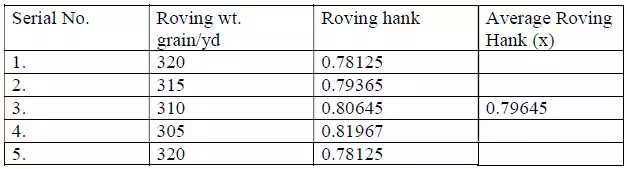

Table-1: Measurement of Roving Hank

|

|

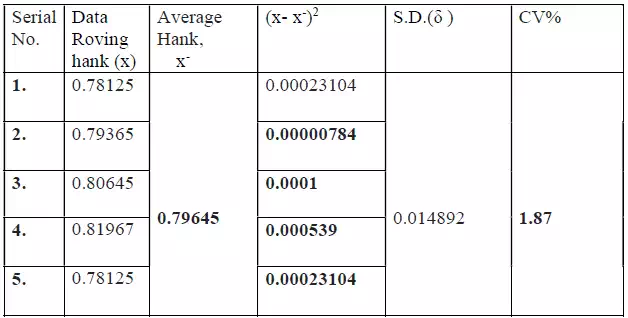

Table-2: Measurement of Roving CV%

|

|

Results:

For roving the count of cotton Roving 0.79645 and CV% is 1.87.

Discussion:

In this Experiment, we should be careful about setting the sliver and roving

between the guide and rubbing guide of wrap block. We should also be precaution

about operating the wrap block (clockwise). The weight of sliver and roving

should be taken very carefully by electric balance. Finally the roving hank and

CV% should be calculated.

Conclusion:

In this experiment, the Roving Hank and CV% has been calculated. It will be

very helpful in our future industrial life.