Measurement of Fabric Strength by Ball Bursting Test Method

Bursting strength

This tear strength is basically used

for knitted, lace, non-woven fabric, parachute fabrics, filters, sacks and

nets etc. It is the uniformly distributed force over a given area applied to

the fabric surface which is needed to break.

There are mainly two types of bursting strength test-

1. Hydraulic or Diaphragm burst

2. Ball burst

Importance of ball

bursting:

1. This method is used to determine the force required to rupture textile fabric by forcing a steel ball through the fabric.

2. Fabrics having more extension that cannot be checked by diaphragm bursting strength test.

3. This test can be carried out on a standard universal strength tester with a suitable attachment.

4. This method used for knitted fabric, non-woven fabric, coated fabric etc.

Sample preparation:

· Using a circular template 12.5 cm in diameter, mark and cut out ten samples of the fabric from random areas so as to be representative of the entire sample.

· No sample shall be taken nearer than 20 cm from the edge of the roll.

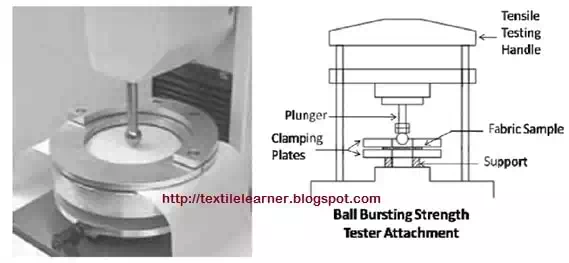

Machine description:

According to US Standard:

· Steel ball having diameter 1 inch (25.4 mm) with a clamp of diameter 1.75 in (44.45 mm).

· Speed of ball = 12 in/min (305mm/min).

· Steel ball is an attachment which is used in the tensile mode on a standard tensile strength testing machine.

· There are not a British Standard for the ball bursting strength of knitted fabrics, although a standard does exist for coated fabrics.

· Steel ball having diameter 25.2 mm with a clamp of diameter 45 mm.

· Speed of ball = 5 mm/sec

Machine diagram:

|

|

|

Fig: Bursting strength test |

Working Procedure:

· Test is carried out using an attachment on standard tensile testing machine.

· Place the sample in the ring clamp as flat as possible with no wrinkles or tension and tighten the clamp.

· In the test, the steel ball is pushed through the stretched fabric and the force required to do so is recorded.

· By the steel ball downward force apply at constant rate until the sample break.

· Ball bursting follow the CRE method.

|

|

|

Fig: Ball bursting machine |

Considering point :

· Sample size should be cut properly by template.

· Sample keep ring clamp as flat as possible without no wrinkle.

· Sample should be tighten properly by the clamp.

Conclusion:

By this article we can learn about the way of testing the strength of fabric by

the ball bursting method. We can also learn about the machine used into this

method and to know about the working description.