Brief discussion of Group marker and its purpose

What is marker?

Marker is sheet of paper where every parts of garments are plotted as per layer or cutting plan. Always the marker man makes marker by breakdown a ratio from PO quantity. As per company working policy; this ration also can be provided by cutting planer. Marker maker input the ratio into marker making software to make desire marker for production. This is the package of garments parts which let us to enhance the cutting production with limited period of time.

As per cutting procedure and product quality issue, the marker man makes different type of marker called group marker & selvage marker. This is very important to go for those special marker if itís required. Letís find it out what is group & selvage marker.

Why do we need to make group marker?

Inspection team sometime gets one kind of dying faults called shedding on fabric so they asking for this special marker to avoided shading problem in ready garments. In a single line we can say that this marker is required when the selected cutting prepared fabric has uneven color formation in meter to meter.

What is group marker?

This is one kind of special marker makes as per quality issue suggested by quality inspection team. Most of the factory placed the inspection department on incoming section. When a fabric comes for production than its need to inspection to sustain product quality. And inspection team seat the fabric to store for storage and relax purpose. Finally cutting department received the fabric and go for bulk cutting.

Group makerís pieces always stick together as much as possible.

Group makerís pieces always stick together as much as possible.

How do they makes group maker?

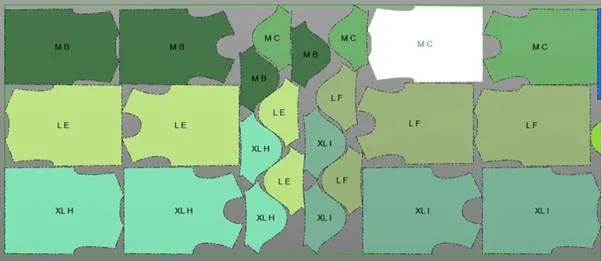

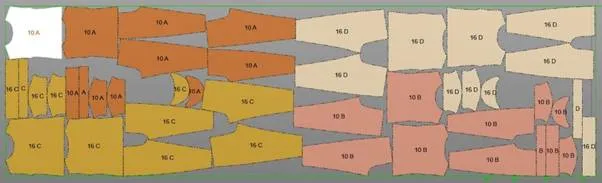

Suppose we are making a marker for a garments where we have to take Back, Front, Sleeve and Moon. Itís required to place all the parts of garments as close as possible. Means all the parts should be placed nearby as a group. This is called group marker.

Group maker always increase the wastage of fabric and reduced the profit for manufacturer.

A good quality fabric can solve this problems.

What is selvage marker?

This is also a group marker but itís has an extra requirement. All the parts of a garments should be placed length wise but stick together as a group like group marker. This type of marker required when inspection observed selvage shedding issue.

Selvage marker always placed the pieces length wise.

Selvage marker always placed the pieces length wise.

Advantage and disadvantage of group marker.

|

S/L |

|

Disadvantage |

|

1 |

Reduce the color shading problems on complete garments |

Increased the fabric wastage & time. |

|

2 |

Increased the garments quality as its standard |

Increased garments making cost and reduce the profit margin. |

|

3 |

Easy to bundling after complete cutting process |

Required so much time to make group marker |

|

4 |

Increased the possibility of Good quality garments. |

Automatic group marker is not good enough to go for cutting so its need to make it manually by placing garments pieces one by one. |

|

5 |

|

Required extra man power to makes lay by different shade wise in cutting department. |