Manufacturing of Manmade Fibers

Manmade fibers are manufactured using different mechanical and chemical processes for example Synthetic fibers from thermoplastics are produced by extruding the molten plastic through extrusion dies (spinnerets) into a stream of cold air that cools and solidifies the plastic. (The operation is referred to as melt spinning.)

General Principles of Production Process

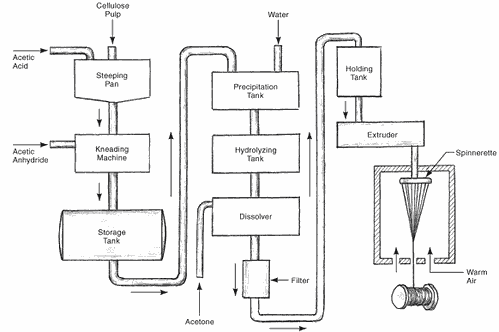

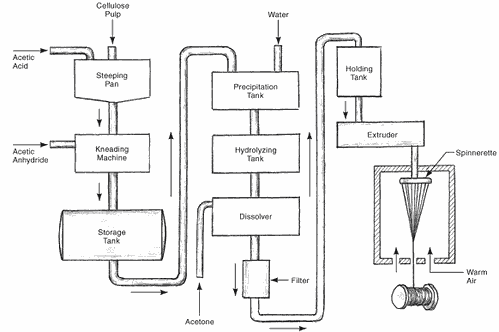

Acetate Fiber Manufacturing

Polymerisation

The

term polymerization defines the process of macromolecules formation through

repetition of basic units: it, of course, applies only to synthesis fibers. In

general, polymerization reactions are activated and controlled during the

process by various parameters, as temperature, pressure,

catalyzers, reaction stabilizers. The number of repetitive units is termed

degree of polymerization and is a parameter of great significance for fiber

properties setting. As the length of the single molecules is not constant but

varies according to a statistical model, the degree of polymerization or the

correspondent molecular weight has to be considered as an average value.

Depending on the various fiber typologies, the degrees of polymerization may range from some hundred units in the case of polymers obtained through condensation (PA, PES) to some thousand units in the case of polymers resulting from poly-addition (PAN, PP). Under a production and application point of view, the degree of polymerization is controlled by measuring following parameters:

- Relative viscosity rel= solution viscosity/solvent viscosity = flow time t1/flow time t2

- Intrinsic viscosity intr= rel /c ?0 (concentration vanishing)

- Melt flow index MFI = speed rate of the melted polymer at pre-established conditions

Relative viscosity is a parameter which is mostly used to identify nylon, while intrinsic viscosity (obtainable from the relative viscosity also by means of formulas) is used for polyester and the melt flow index for polypropylene.

There are basically two mechanisms of chemical reaction available for the synthesis of linear polymers:

- Poly-condensation: with this operation two molecules of the same type or of different types are joined together to form macromolecules by removing simple secondary products as water, hydrochloric acid, alcohol. The prerequisite for reactions of this type is the presence in the molecule (monomer) of two terminal reactive groups with functional properties.

- Poly-addition: this operation joins together several molecules and redistributes the valence links existing in the monomers, however without removing secondary products.

Many

unsaturated compounds which are characterized by the presence of a double link

between

two adjacent carbon atoms as ethylene and its derivatives polymerise according

to this reaction;

within this category fall e.g. acrylic and polyolefin fibers.

Spinning

The term spinning defines the extrusion process through bored devices (spinnerets) of fluid polymer masses which are able to solidify in a continuous flow. The spinning process is sometimes designated as “chemical or primary spinning” to distinguish it from the “textile or mechanical or secondary spinning”. The polymer processing from the solid to the fluid state can take place with two methods:

by melting:

this method can be applied on thermoplastic polymers which show stable performances at the processing temperatures (this method is used by 70% of the fibers)

by solution:

the polymer is solved in variable concentrations according to the kind of polymer and of solvent, anyhow such as to produce a sufficiently viscous liquid (dope) (this method is used by 30% of the fibers)

Solvent removal can take place in two ways:

- Dry spinning

The solvent is removed through flows of warm gas suitably directed to the extruded filaments; gas temperature should be higher than the boiling temperature of the solvent, which will be extracted from the filaments, recovered and recycled. Filament solidification proceeds according to the extent of solvent evaporation; it takes place faster on the external yarn layers (thus creating a crust or skin), and successively slows down while proceeding towards the interior. As a consequence of the mass exchange, the original (round) cross-section of the filament undergoes a contraction, thus generating cross-sections which characterize the various kinds of fibers and spinning processes.

- Wet spinning

This spinning method is based on the introduction of an extruded polymeric viscose into coagulation baths where the liquor, usually water, behaves as a solvent towards the polymer solvent and as a non-solvent towards the polymer mass.

Practically

the solvent which is contained in the fiber in the amorphous state (gel) is

spread towards the liquor and at the same time, the liquid of the bath is

spread towards the interior of the fiber. The processing speeds are dependent

on several parameters, as type and concentration of the

polymeric solvent and of the liquor, which bring about structural variations in

the fiber. In particular the formation of an outer gardened and more compact

cortex (skin), similarly to what happens in dry spinning, slows down the

coagulation mechanism of the inner filament portion (core), thus creating

unevenness with a more or less porous structure (voids formation). The fiber

cross-sections result more or less modified, from the original round form to a

lobated form, with a wrinkled surface.

Drawing

The polymer extruded by the spinnerets in form of filaments has not yet the properties which are typical of a textile fibre: in fact the polymer mass (solidified through cooling or solvent removal) is characterized by a mass of disorderly placed molecular chains (in amorphous state) which provides the material with poor thermal and chemical stability, low resistance to ageing, high plasticity and deformability and consequently insufficient physical/textile properties. If we take natural fibers as models, we need to orientate the molecular chains (orientation phase) in the direction of the fiber axis and at the same time or successively activate or increase the ordered arrangement of the intermolecular structure (crystallization phase).

Continuous filament yarns

Continuous filament yarns can be composed of a single filament (monofilament yarns) or of several filaments (multifilament yarns) and are described through abbreviations, the first figure of which indicates the total linear mass (expressed in dtex or, less usually, in den), the second figure indicates the filament number and a third figure if any shows the twists per length unit (turns/m) imparted to the yarn.

Monofilaments for traditional textile uses have linear masses ranging from 10 to 50 dtex approximately; monofilaments with larger linear masses find on the contrary use in technical applications and are identified with their thickness expressed by the diameter of the round cross-section (0.06?2 mm).

General principles of manmade fiber manufacturing

There is no substantial difference in the structure of natural fibers from that of man-made Fibres: both fiber categories are composed of macromolecules or by linear polymers, that is by the repetition of several simple molecules (monomers). Man-made fibers are fibers in which either the basic chemical units have been formed by chemical synthesis followed by fiber formation or the polymers from natural sources have been dissolved and regenerated after passage through a spinneret to form fibers. Those fibers made by chemical synthesis are often called synthetic fibers, while fibers regenerated from natural polymer sources are called regenerated fibers or natural polymer fibers. In other words, all synthetic fibers and regenerated fibers are man-made fibers, since man is involved in the actual fiber formation process.

Natural fibers are essentially composed of atoms of various elements, such as carbon, hydrogen, oxygen, sometimes of nitrogen and other elements (sulphur) in lower quantities; during their biological growth, these elements form the rings of long molecular chains. The development of man-made fibres was based on the knowledge acquired with natural fibers which structure was taken as a model; the difference between the two fiber categories is that natural fibres form macromolecules through biological growth, while the growth process of man-made fibres is driven by technical equipment (artificial fibers use instead of natural polymers).