Processing And Fabrication

Spinning

Polymer that is to be converted into fibre must first be converted to a liquid or semiliquid state, either by being dissolved in a solvent or by being heated until molten. This process frees the long molecules from close association with one another, allowing them to move independently. The resulting liquid is extruded through small holes in a device known as a spinnerette, emerging as fine jets of liquid that harden to form solid rods with all the superficial characteristics of a very long fibre, or filament. This extrusion of liquid fibre-forming polymer, followed by hardening to form filaments, is called spinning (a term that is actually more properly used in connection with textile manufacturing). Several spinning techniques are used in the production of man-made fibre, including solution spinning (wet or dry), melt spinning, gel spinning (a variant on solution spinning), and emulsion spinning (another variation of solution spinning).

Solution spinning

One of the oldest methods for the preparation of man-made fibres is solution spinning, which was introduced industrially at the end of the 19th century. Solution spinning includes wet spinning and dry spinning. The former method was first used to produce rayon fibres, and the latter method was used to spin cellulose triacetate to acetate fibres. In both methods, a viscous solution of polymer is pumped through a filter and then passed through the fine holes of a spinnerette. The solvent is subsequently removed, leaving a fibre.

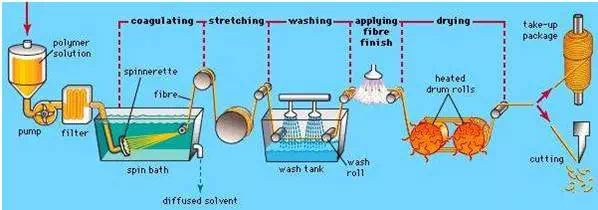

The wet-spinning process is illustrated schematically in Figure 1. During wet spinning the spinnerette is generally (but not always) placed in the spin bath, a coagulation bath in which solvent diffuses out of the extruded material and a nonsolvent, usually water, diffuses into the extrudate. The resulting gel may be oriented by stretching during this stage, as the polymer is coagulated, or the freshly formed fibres may be stretched after they are removed from the spin bath. At this point the fibre, containing solvent and nonsolvent (e.g., water), is washed with more nonsolvent (again, usually water). A lubricant, referred to as the fibre finish, is generally applied before the fibre is dried on large, heated drum rolls. The fibre is then wound onto spindles or sent to a cutter. The cutter produces fibre in lengths of 2.5 to 15 cm (1 to 6 inches) known as staple. A spindle that has been fully wound with continuous fibre is called a package.

Figure 1: Stages in the wet spinning of polymeric fibres.

In dry spinning, the solution of polymer is pushed through a spinnerette into a heated column called the spinning tower, where the solvent evaporates, leaving a fibre. The emerging fibre may contain solvent that may have to be removed by further heating or by washing. This operation is followed by stretching, application of finish, and either take-up on a spindle or cutting to staple.

The wet-spinning method is capable of spinning a large number of fibres at a time because several thousand holes may be present in a single spinnerette. The large bundle of emerging fibres, known as tow, can be spun at rates slow enough to make possible the use of a large spin bath and large washing rolls, drying rolls, and other processing equipment. Wet spinning is thus highly economical, the low spinning rates being compensated for by the large tows to give high overall productivity. In dry spinning, on the other hand, the rate of spinning is much higher, but relatively small bundles of fibre are extruded in order to achieve adequate solvent removal and drying. As a consequence, productivity is lower than in wet spinning. Dry spinning is being phased out for most commodity fibres and is used only for expensive specialty fibres, such as spandex, that cannot be spun by any other process.

The use of solvents that can be recovered from the spin bath is becoming more common in solution spinning. Acrylic fibres are an example of this trend. In some older acrylic processes the solvents were salts such as sodium or ammonium thiocyanates, but the preferred method now is to use an amide-type solvent—e.g., N,N-dimethylacetamide (DMAc)—which can be recovered from the spin bath by distillation. Amide solvents are also used for the spinning of some aramids—e.g., for the trademarked fibres Nomex and Conex.

Rayon fibres traditionally have been spun from xanthate solutions, as noted above, but this process has been abandoned in developed countries owing to environmental problems caused by the carbon disulfide ingredients and also by salts produced in treating the xanthate with acid. Newer plants use an inorganic solvent, morpholine N-oxide, which can be recovered by distillation of the spin bath.

Melt spinning

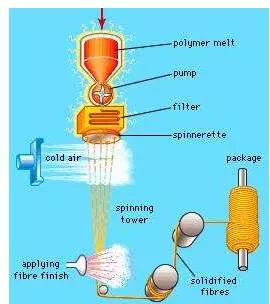

The most economical method of spinning is melt spinning, primarily because there is no solvent to be recovered as in solution spinning and because the spinning rates are so high. In this process (illustrated schematically in Figure 2), a viscous melt of polymer is extruded through a spinnerette containing many holes (but not nearly so many as in solution spinning) into a process zone called the spinning tower. There the molten polymer is solidified by a blast of cold air, and the numerous fibres are collected, after application of finish, at high speed. In a process known as spin-drawing, fibres may be drawn in-line to several times their original length. Packages may be collected directly from the spinning tower to give what is called continuous filament, or several lines of fibre may be collected into a large tow for cutting to staple.

Figure 2: Stages in the melt spinning of polymeric fibres.

Some filaments may be melt-spun through a single-hole spinnerette to yield a monofilament that is of much larger diameter than usual textile fibres. Drawing may be done in-line or as a separate step. The monofilaments are used for such products as fishing line and lawn furniture.

Gel spinning

Gel spinning is an old technique that has come into use commercially only since the 1980s. As originally applied, solutions of very high solid contents (20–80 percent) were used; such solutions were similar to semisolids. In the modern adaptation of this process, polymer of an extremely high molecular weight is dissolved in a solvent of low concentration (i.e., 1 to 2 percent), making a very viscous solution. This solution is either dry- or wet-spun to fibre, which, still retaining most of the solvent, is actually a gel of polymer and solvent. While in the gel state, the fibre can be stretched in order to pull the molecules of the polymer into an elongated state, instead of the usual solid state of chain-folded molecules. Ultrahigh-strength, high-stiffness polyethylene fibres, marketed under such trademarks as Spectra, are commercially produced using gel-spinning techniques.

Emulsion spinning

Some nonmelting and insoluble polymers can be ground to a finely divided powder, mixed into a solution of another polymer, and solution-spun to fibres. The soluble polymer can be removed by a solvent or by burning and the residual fibre collected. Such a process can be used to make fibres of fluorocarbons such as Teflon (trademark), which have extremely high melting points. Even materials that are not polymers—e.g., inorganic materials such as ceramics—can be suspended in a solution of a cheap polymer such as cellulose and spun to fibre. The cellulose can be burned away to leave a sintered mass in fibre form. Such fibres are used as replacements for hazardous asbestos fibres.

Split-film fibres

Very cheap fibres for use in applications that cannot justify the cost of fibres spun by the usual methods (for instance, packaging materials) may be prepared by the split-film method. This process consists of extruding a polymer such as polypropylene through a die to obtain a ribbon, which is then passed through numerous cutting blades that slit the ribbon or film into continuous smaller ribbons resembling very coarse fibres. This process, which produces crude but very useful fibres, is frequently practiced on-site by the user of the final product.

Drawing

Stretching and orientation

The spinning processes described above produce some orientation of the long polymers that form spun filaments. Orientation is completed by stretching, or drawing, the filament, a process that pulls the long polymer chains into alignment along the longitudinal axis of the fibre and causes them to pack closely together and develop cohesion.

fibre, man-made; human nervous system: brainDeveloping multifunctional fibres to deliver optical signals or drugs directly into the brain and to record neural activity

Wherever the polymer chains are able to pack closely together in a fibre, there is a tendency toward an ordered arrangement of the atoms with respect to one another. These tightly packed bundles of molecules are called crystallites, because they are regions that possess the regular and precise arrangement of atoms characteristic of all crystals. Between the crystallites are regions in which the molecules have not been able to align themselves so precisely. These are called amorphous, or noncrystalline, regions. In considering fibre structure, then, the polymer chains may be regarded as regions of ordered crystalline arrangement embedded in amorphous material. During the drawing operation the polymer chains slide over one another as they are pulled into alignment along the longitudinal axis of the fibre. As drawing continues, more and more of the molecules are brought to a state where they can pack alongside one another into crystallites. In these regions the molecules are able to hold tightly together as a result of intermolecular forces and resist further movement with respect to one another. For instance, after nylon is spun, the filament may be drawn to as much as five times its original length before it resists further stretching. At this point the molecules are aligned as effectively as possible into crystalline regions and are holding tightly together. The filament is then able to withstand great force without further stretching.

The degree of alignment of fibre molecules affects the properties of a fibre in several ways. The more closely the molecules pack together, the greater is the ultimate strength, or breaking strength, of the fibre. This increase in ultimate strength is accompanied by a decrease in the amount of elongation that the fibre can sustain before reaching its breaking point; the molecules are not able to slide over one another as they could before alignment took place. If the load becomes too great, the fibre will rupture. Because the closely packed molecules no longer have great freedom of movement, a high degree of orientation also tends to increase fibre stiffness or rigidity.

Water is unable to penetrate between molecules in the crystalline region of a fibre as well as it penetrates the amorphous regions; therefore, increased alignment tends to lower the moisture absorption of the fibre. Increased resistance to water penetration in turn affects the dyeing properties of highly oriented fibres; the molecules of dyestuff cannot migrate from the dye bath into the spaces between the fibre molecules. Increased resistance to penetration by foreign molecules also improves the general chemical stability of a fibre, since highly oriented fibres are more resistant to chemical attack. Fibres change in appearance as they are drawn. In the undrawn state, nylon is usually dull and opaque; as the filaments are drawn and molecular orientation increases, the filaments acquire the transparency and lustre characteristic of drawn nylon.

Drawing techniques

Fibres can be drawn either as an integral part of the spinning operation or in a separate step. Fibres such as nylon and polypropylene can be drawn without applying external heat (or at a temperature no greater than about 70 °C [160 °F])—a process referred to as cold drawing. Other fibres, such as polyester, that are spun at extremely high rates yield what is known as partially oriented yarns (POY)—i.e., filaments that are partially drawn and partially crystallized and that can be drawn at a later time during textile operations. Many fibres, such as PET, require that a hot-drawing step follow the spinning process fairly soon, or they will become brittle. Avoiding such brittleness is part of the reason for preparing partially oriented yarns. Acrylics may receive a hot-drawing (known as plastic stretch) following drying, but a portion of the molecular orientation is relaxed by a subsequent annealing step, which uses steam under pressure to prevent the fibres from pilling when rubbed during use. Nylon intended for ultrahigh-strength end uses such as tire cord requires hot drawing; aramids also can be greatly improved by this process. For instance, continuous-filament Nomex, a trademarked aramid, is hot-drawn to give a tensile strength nearly double that of the as-spun product used for staple. Kevlar 29, another trademarked aramid, is drawn at a temperature over 400 °C (750 °F) to produce Kevlar 49, a fibre with nearly double the stiffness of the undrawn product.

Texturing

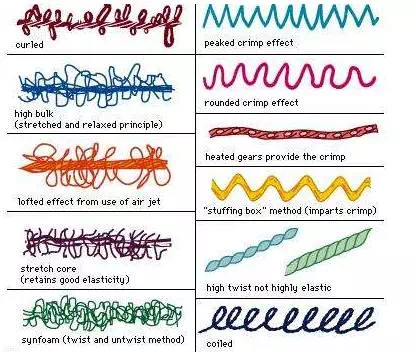

Texturing is the formation of crimp, loops, coils, or crinkles in filaments. Such changes in the physical form of a fibre (several examples of which are shown in Figure 3) affect the behaviour and hand of fabrics made from them. Hand, or handle, is a general term for the characteristics perceived by the sense of touch when a fabric is held in the hand, such as drapability, softness, elasticity, coolness or warmth, stiffness, roughness, and resilience.

Examples of textured yarns.

For continuous yarns used in apparel, a number of texturing processes may be employed either in a textile factory or by the fibre producer. In the latter case the yarns are referred to as producer-textured yarns. Most apparel texturizing techniques are high-speed processes. Processes for large tows may run at lower speeds but at higher volume.

Crimping

In order for staple fibres to be spun into yarn, they must have a waviness, or crimp, similar to that of wool. This crimp may be introduced mechanically by passing the filament between gearlike rolls. It can also be produced chemically by controlling the coagulation of a filament in order to create a fibre having an asymmetrical cross section—that is, with one side thick-skinned and almost smooth and the other side thin-skinned and almost serrated. When wet, such fibres swell to a greater extent on the thin-skinned side than on the thick-skinned side, causing a tendency to curl.

A similar effect can be produced from bicomponent fibres. These are fibres spun from two different types of polymer, which are extruded through holes set side-by-side in such a way that the two filaments join as they coagulate. When the filament is drawn, the two polymers extend to different degrees, producing a helical crimp when the strain is relaxed.

One popular texturizing process is false-twisting. In this technique, twist is inserted into a heated multifilament yarn running at high speed. The yarn is cooled in a highly twisted state, so that the twist geometry is set, and then the yarn is untwisted. Untwisting leaves filaments that are still highly convoluted, allowing the production of a textured yarn of much greater volume than the yarn would be in an untextured state.

False-twist texture is usually combined with drawing. Partially oriented (POY) nylon and polyester, which have been spun at extremely high rates and are already partially crystalline, are both drawn and textured in this way.

Stuffing

Fibres spun from very large bundles of fibre, called tow, are generally crimped in-line by feeding two tows into a stuffer box, where the tows fold and compress against each other to form a plug of yarn. The plug may be heated by steam injection so that, upon cooling, a zigzag crimp is set in the filaments. Following crimping, the tow is cut to staple and baled for shipping to the textile manufacturer.

Knit-deknitting

Knit-deknit texturing may be used on drawn fibre in order to produce crimp of a knitted-loop shape. In this process a yarn is knitted into a tubular fabric, set in place by means of heat, and then unraveled to produce textured yarn.

Air jet

Air-jet texturing is used with a single type of yarn or with a blend of filament yarns. In the latter case fancy yarn mixtures are obtained. This method of texturing is carried out by feeding a wet yarn or a dry yarn plus a small amount of water into a high-speed jet of air. Yarns textured in such a process contain a large number of very fine filaments, however, increasing the probability of entanglement.