Physical classification of Fibers

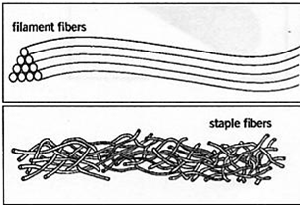

Fibers are broadly classified into Filament yarns and Staple Yarns on the basis of their physical structure.Filament yarns are measured in yards or meters.

Fiberís Diameter Analyses

The diameter of a fiber is the distance across the fiberís cross-section.The diameter of the natural staple fiber is irregular and varies from one part of fiber to another. Staple fibers diameters are measured in microns. The diameter of the smooth, even manmade filament fibers is uniform. The diameter of man-made fibers can be controlled during the manufacturing process by changing the size of the opening in the spinneret. The size of the spinneret openings ranging from fine to heavy. The small opening, produce fine filament fibers. Filament fiber diameters are measured in denier. Natural or manmade fibers can be altered or changed purposely to produce irregularities for special or novelty effects.

Physical Classification of Fibers

A fiber

can be described as any substance natural or manufactured that is suitable

for being processed into a fabric. Fiber properties include length

(staple or filament), size and surface contour. These

properties affect the end use such as serviceability, aesthetics,

durability, comfort, retention, and care.

To create a fabric, fibers are spun into yarns and then woven into a

fabric. Through these processes, a fabricís characteristics can be

manipulated through blending, manipulation of the fiber and other methods.

Look through a microscope and the secret to any fabric is beneath the

surface.

Filament Fibers:

All fibers having a practically unlimited or infinite length are called filaments. Filament fibers are continuous (long) fiber. It may be natural like silk or synthetic like Nylon.† Filament fibers are measured in yards or meters. Silk, in filament form, is reeled from cocoons. Man-made fibers of a chemical composition, liquid nature are forced through spinnerets, hardened and produced into continuous filament strands of a determined length. When filament fibers are planned to be cut into staple fibers, a large spinneret with many openings are used. The filament fibers are grouped into a bundle referred to as a tow and then cut into the desired staple length. Line or low man-made fibers are manufactured in continuous strands of any desired length. The tows may be cut into staple lengths or flocks based on specific end use.

Staple Fibers:

Any fiber with a practical, limited or finite length is called ďStaple FiberĒ These are small length fiber like cotton, wool, jute etc. it may be natural (Cotton) or man-made (Viscose rayon, Polyester).†† The length of the fiber varies within a fiber of the same source and also between varieties obtained from different sources. Staple fibers are measured in inches or centimeters. Staple fibers include almost all natural fibers except silk. Silk is a natural filament fiber and may be cut up to form short staple fibers. Staple fibers must be spun or twisted together to make a long continuous strand of yarn. They may also be used in their staple form to produce non-woven or felted fabrics.

A staple is the fiber of cotton, wool or ramie etc of no more than a few inches long. A filament is usually a man-made fiber of indefinite length. All fabrics woven, knitted or crocheted are made from yarn. The size of yarn has usually related the weight of the fabric eg. heavy fabrics use thick yarns, for light fabrics fine yarn is used. There are 2 kinds of yarns used in textile fibers they are spun yarn and filament yarn and use 3 different systems to control the size.