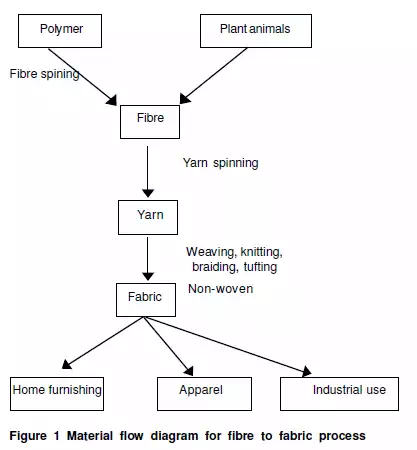

METHODS OF FABRIC FORMING

The most commonly used fabric forming methods are weaving, braiding, knitting, felting, tufting and nonwoven manufacturing. However, major method of fabric construction is weaving.

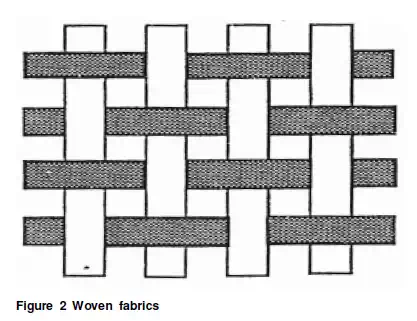

Weaving

Weaving is the interlacing of warp and filling yarns perpendicular to each other. There are practically an endless number of ways of interlacing warp and filling yarns. Each different way results a different fabric structure. Approximately 70% of the fabrics made in the world are woven fabrics. Figure 2 shows the diagram of woven fabrics.

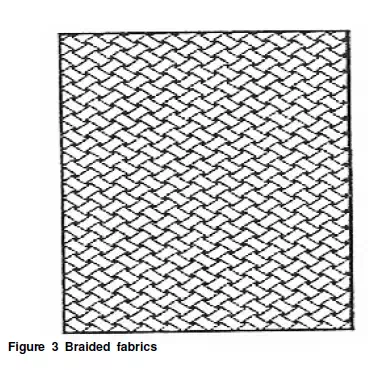

Braiding

Braiding is probably the simplest way of fabric formation. A braided fabric is formed by diagonal interlacing of yarns. Although there are two sets of yarns involved in the process, these are not termed as warps and fillings as in the case of woven fabrics. Each set of yarns moves in an opposite direction. Braiding does not require shedding, filling insertion, and beat up. Figure 3 shows the diagram of braded fabrics.

Knitting

Knitting refers to interloping of one yarn system into vertical columns and horizontal rows of loops called wales and courses, respectively.

There are two main types of knitting:

· weft knitting

· warp knitting.

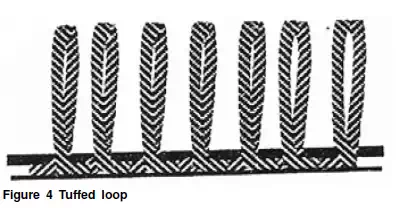

Tufting

Tufting is the process of manufacturing some categories of carpets and similar structures. In this process surface yarn system of loops is 'sewn' or 'stitched' through a primary backing fabric, usually a woven or nonwoven fabric. The loops are arranged in vertical columns (rows) and horizontal lines (stitches). Loops can be in the form of cut or uncut loops (piles) or a combination of thereof. The fabric is usually back-coated in a later process to secure tufted loops. Orientation of tuffed loops is shown in Figure 4.

Bonding

Bonding is the method of manufacturing nonwovens using textile, paper, extrusion, or combination of these technologies, to form and bond polymers, fibres, filaments, yarns or combination sheets into a flexible, porous structure. In fact, some nonwoven products are subjected to both textile and paper industry. Figure 5 shows the bonding of nonoven fabric.