5 Things

to Look Out for in Plastic Prototyping

A great way to determine if your part will function as designed

is by creating a prototype. Prototypes have the amazing ability to transform

your work into something tangible and make your idea come to life.

Plastic prototyping has opened up a whole new world of possibilities.

Unlike previous methods that involve pencil and paper, plastic prototyping

combines art and science to turn your idea into three-dimensional

reality. Plus, plastic parts are particularly inexpensive and can be

easily moldedinto any form.

From stereo lithography to prototypes in medicine, there are

countless uses for the material. Check out these latest advancements and

innovations in plastic prototyping:

● Re-design and

Re-prototype

Since it has been introduced, 3D printers have

been constantly going through improvements. A virtual design, such as a

Computer Aided Design (CAD) file, is created with a scanner or modelling

application to make a digital copy. When the 3D object is printed, it is

created by adding one thin layer at a time. Although you can use other

materials like metal, plastic is the ideal material to create an inexpensive

prototype of your design. Since plastic is easy to shape, you can make

adjustments to your existing prototype by applying another printed piece. It is

also environmentally friendly since it can be reused multiple times.

Thanks to recent progress, 3D printers have diversified and

allow much more flexibility. You can personalize your experience by selecting

from multiple options. Stereolithography (SLA,)

for instance, converts liquid plastic into objects. This may

be suitable for you if you’re looking to create an inexpensive prototype

rapidly. You also have the option of combining different methods to create

multiple parts. Another 3D technology used for prototyping is the Laminated Object

Manufacturing (LOM) process, which involves adding pressure and heat to fuse

plastic layers together before cutting the product with a computer controlled

laser or knife.

● 3D art

(Image source: Wired)

Recently, 3D printers have inspired many individuals to boost

their creativity. Artists have taken advantage of the new gadget to create

everything from sculptures to jewelry. Unlike

photography or other forms of art, 3D printing is an entirely new concept with

a large room for creativity and originality. Artists can choose to create the

entire work with the 3D printer or add printed items to enhance their work.

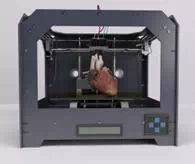

● Plastic prototypes in

medicine

One of the greatest advantages of plastic prototyping is the

benefits in medicine. For the first time, printers are used to replicate human

body parts with 3D printed body parts. Instead of looking at a drawing or a

photo of the body, surgeons can look at the prototype to plan and practice the

complex surgeries. In addition to these benefits, the plastic prototypes can be

used to educate aspiring surgeons. Plastic is extremely light and easy to

transfer from one location to another. Plus, it’s cheap and easy to reuse.

Since the design determines the outcome of the 3D replica, professors can

better educate their students by choosing and constructing the design that will

be the most beneficial.

● Refabricator

(Image source: Cosmic Log)

Plastic prototyping may literally be out of this world.

NASA started experimenting with a device called the Refabricator, which can print 3D objects and reuse the

plastic. This will reduce the problem of the limited amount of weight that can

be brought into space. The Refabricator allows

astronauts to reuse the plastic and use the machine to adapt to unexpected

situations. For instance, the astronaut can recycle a food tray and create a

necessary tool. Although the Refabricator has

not yet been sent into space, there are ongoing experiments to explore the

unlimited possibilities of having a 3D printer in space.

● 3D printing pen

(Image source: 3Doodler)

You can draw in thin air with the world’s first 3d printing pen.

Using melted plastic, the 3Doodler allows users to create tangible prototypes.

Although it is similar to the 3D printer, the pen allows the individual to do

the work instead of designing the work for the computer to complete. The user

can create a detailed design with the small tip of the pen and control the

thickness of the plastic with speed. Like the printer, the 3D printing pen also

lets users to create their own pieces of art or add plastic parts on to

existing objects. Users can take advantage of the 3D printing pen by enhancing their prototypes with

additional features.

Plastic prototyping allows you to explore different options to

make adjustments and improve your part. Since plastic is inexpensive and easy

to mold, you can test the functionality of the

design and show others that you’re serious about the product.