Neutron

Radiography Testing

Also known as: Neutron Imaging, N-Ray Radiography, Neutron

Tomography

|

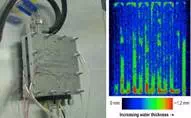

Similar to x-ray radiography, neutron radiography is a

very efficient tool to enhance investigations in the field of non-destructive

testing (NDT) as well as in many fundamental research applications. Neutron

radiography is, however, suitable for a number of tasks impossible for

conventional x-ray radiography. The advantage of neutrons compared to x-rays

is the ability to image light elements (i.e. with low atomic numbers) such as

hydrogen, water, carbon etc. In addition, neutrons penetrate heavy elements (i.e.

with high atomic numbers) such as lead, titanium etc. allowing the study of

materials in complex sample environments, for example water accumulation in

hydrogen fuel cells: see Fig. 1. Because neutrons interact with the nucleus

rather than with the electron shell, they can also distinguish between

different isotopes of the same element. This makes neutron radiography an

important tool in various research applications and in the field of NDT. The

MNRC high neutron intensity beams permit short exposure times, high spatial

resolution and high sample throughput. |

Fig. 1. Left: Photograph of a hydrogen fuel cell.

Right: False colored neutron radiograph

of a fuel cell showing the water content of the cell during operation. |

||||||||||||

|

Methods of neutron radiography The detection of neutrons relies on a conversion into

visible light; to achieve this, conversion screens containing either Gd or 6Li and a fluorescence

material are commonly used. After the conversion the emitted light can be

detected by different media such as: ● Film, that is then developed in a dark room and results

in a permanent image, ● Imaging Plates, that can be re-used after being

processed by an image reader. (The technology is very similar to x-ray

imaging plates used at medical offices), ● Digital cameras (CCD, CMOS), allow to capture the image

digitally. Differences between neutron and x-ray radiography Neutron radiography is based on the principal that

neutrons interact with the nucleus of the atom, rather than the electrons.

Therefore neutrons are absorbed in matter very differently from x-rays and

gamma rays. This means that, contrary to x-rays, neutrons are attenuated by

some light materials, such as hydrogen, boron and lithium, but penetrate many

heavy materials such as titanium and lead. This allows for some unique

applications of neutron radiography. The figures below impressively demonstrate how neutron radiography

can yield different yet complementary information to x-ray radiography.

Applications Neutron Radiography has a wide range of uses, including: ● Imaging casting to ensure that the mold materials don't carry into the castings as

impurities. ● Validating the proper fill of pyrotechnical in actuators ● Studying the flow of oil in automobile transmissions ● Facilitate Fluid flow analysis ● Analyze O-ring

placements ● Image carbon, gun powder grain structure, plastics,

lead, and other heavy metals. |

|||||||||||||

● Testing air-cooled jet engine turbine

blades for residual core material and other cooling passage blockages.

● Reliability testing of detonators in

explosive devices.

● The inspection of high-reliability

explosives for presence of transmitters and receivers and for explosive loading

uniformity.

● Inspecting for internal flaws such as

cracks, inclusions, voids, bubbles, foreign materials, density variations and

misalignments.

● Testing braze quality and the presence

of braze materials in manufactured parts.

● Determining capacitor delamination.

● Determining bonding flaws in adhesives.

● Inspecting radioactive objects such as a

gamma source in its shielding.

● Determining reliability of air bag or

parachute initiators.

● Inspection of artifacts uncovered

through archaeological digs.

● Inspecting for aluminum corrosion

products.

● Testing for missing or misplaced O-rings.

● Testing for hydrogenous foreign

substances in sealed units.

How does Neutron Radiography NDT testing work?

The nondestructive inspection

of a material using neutron imaging is very similar to the process used

in X-Ray NDT; however, unlike x-rays, n-ray radiography services

allow the imaging of organic materials inside a component. Metals in the

subject component take on a transparent appearance in neutron radiographic

images. In many cases, x-ray and neutron radiography are complementary NDT

inspection processes, offering a complete picture not only the integrity of the

component, but also of the organics within that component.