SCM - Agile and Reverse

In this chapter,

we will throw some light on two specialized supply chains −

● Agile Supply Chain

● Reverse Supply Chain

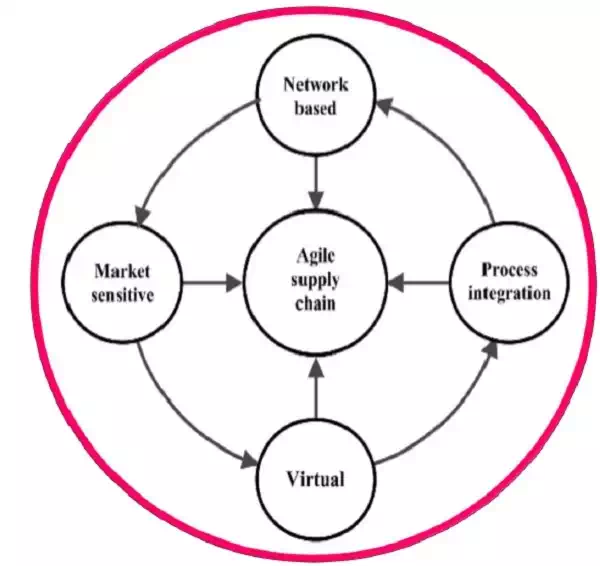

Agile Supply Chain

An agile supply

chain can be defined as a chain of supply that has the potential to respond to

changing requirements in a way that accelerates the delivery of ordered goods

to customers.

In simple words,

supply chain agility is a custom adopted by many companies for choosing a

dealer. As we know, a supply chain with flexibility and the ability to quickly

react to emergency requirements can help the business answer more efficiently

to its customers. Apart from flexibility, speed and accuracy are also signature

marks of this type of supply chain.

To acknowledge the

advantages of an agile supply chain, we have to learn about the elements of any

type of supply chain. These include elements like collection of orders and

processing, supply of materials to create the goods used to complete orders,

packaging and transport of finished goods, and the quality of customer service

that is advertised throughout the process from the point of sale to the actual

delivery and beyond.

Thus, for

considering the functions of supply chain as agile, each one of these elements

must be managed efficiently and coordinated in such a way that makes it

possible to adapt to changing circumstances.

With the help of

an agile supply chain, merchants can easily respond to the varying requirements

of customer with relatively less time required. For example, if a client has

already placed a sizable order but demands the product to be delivered few days

prior to the projected delivery date, a merchant with a truly agile supply

chain can easily accommodate that change in the clientís situation, at least in

part. Working collaboratively, the merchant and the customer develop a strategy

to permit the delivery of as much of the order as possible within the new time

frame required.

There are times

when merchants need to think creatively along with some flexibility in terms of

scheduling production time, selecting shippers and basically looking closely at

each step in the order completion process to search for ways to reduce the time

required to successfully accomplish those tasks and abide with the customerís

request.

Reverse Supply Chain

Reverse supply

chain states the evolution of products from customer to merchant. This is the

reverse of the traditional supply chain evolution of products from merchant to

customer.

Reverse logistics

is the process of planning, executing, monitoring and controlling the efficient

and effective inbound flow and storage of secondary goods and information

related to the purpose of recovering value or proper disposal. Some examples of

reverse supply chain are as follows −

● Product returns and handling

product displacement.

● Remanufacturing and

refurbishing exercises.

● Management and sale of

surplus, along with returned equipment and machines from the hardware leasing

business.

Different types of

reverse supply chain arise at different stages of the product cycle. Mostly

reverse supply chain is designed to carry out the below given five key

processes −

● Product acquisition − Accumulating the used product

from the user by the reseller or manufacturer because of some manufacturing

defect or some other reason. It is basically considered as a companyís growth

strategy.

● Reverse logistics − Shipping of products from

their final destination for auditing, sorting and disposition.

● Inspection and disposition − Examining the condition of

the product returned along with making the most profitable decision for reusing

it in some other way.

● Remanufacturing or

refurnishing − Returning the product to its

original source from where it was ordered in the very first place along with

specifications. This is done basically when there is a manufacturing or

furnishing defect in the goods.

● Marketing − Establishing secondary

markets for the goods that have been recovered by the merchant from the client

who initially ordered it in the beginning but chose to return it.

In short, we can

say that the enterprises that closely coordinate with their forward supply

chains are the one that have been most successful with their reverse supply

chains. These two chains create a closed-loop system. For example, the company

designs a product layout according to the manufacturing decisions followed by

recycling and reconditioning. Bosch is a beautiful example of reverse supply

chain. It constructs sensors into the motors of its power tools, which signs if

the motor is worth reconditioning.

Technology plays a

great role here by reducing the inspection and disposition costs, sanctioning

the company to make a profit on the remanufactured tools. In fact, along with

reverse supply chains, forward thinking results in big dividends.