WHAT IS A SYNCHRO/RESOLVER?

Synchro: Transducer that uses a transformer whose primary-to-secondary coupling may be altered by changing the relative orientation of the two windings. Synchros are often used for measuring the angle of a rotating machine or in case of selsyn (self-synchronous) configuration, used for controlling position of a device. In its general physical construction, it is much like an electric motor. The primary winding of the transformer, fixed to the rotor, is excited by an alternating current causes voltages to appear between the Y-connected secondary windings fixed spatially at 120 degrees to each other on the stator. The voltages are measured and used to determine the angle of the rotor relative to the stator.

Resolver: Type of rotary electrical transformer used for measuring degrees of rotation. The name resolver comes from resolving an angular input in to its x and y components. It is considered an analog device, and has digital counterparts such as the digital resolver, rotary (pulse) encoder.

Synchro/Resolvers allow you to monitor and control:

· Position of a flap on an aircraft wing

· Control stick of a helicopter

· Turret position of a military tank

· Throttle position of an aircraft

· Orientation of an antenna platform

· First used in the control system of the Panama Canal in the early 1900s to transmit lock gate/valve stem positions, and water levels

· Fire-control system designs developed during World War II to transmit angular information from guns and sights to an analog fire control computer, and to transmit the desired gun position back to the gun location

· Smaller synchros were used to remotely drive indicator gauges and as rotary position sensors for aircraft control surfaces

· Large synchros were used on naval warships, such as destroyers, to operate the steering gear from the wheel on the bridge

Back to Top

There are two types of synchro systems: torque systems and control systems.

Torque system: a system in which the transmitted signal does the usable work. In such a system, accuracy on the order of one degree is attainable.

Control system: a synchro will provide a voltage for conversion to torque through an amplifier and a servomotor. Control type synchros are used in applications that require large torques or high accuracy such as follow-up links and error detectors in servo, automatic control systems (such as an autopilot system). In simpler terms, a control synchro system is a system in which the transmitted signal controls a source of power which does the usable work.

We have designed our data acquisition hardware to be software flexible. That means you can use a variety of programming languages and programs with our UEI I/O boards. One particularly popular program used is National Instrument’s ‘LabVIEW’. We supply these samples so you can create a standard acquisition application in the shortest time possible. UEI supports a variety of acquisition modes (Buffered IO, Simple IO, Messaging IO, DMap IO) which can be accessed through the simple pull downs.

Our extensive collection of prebuilt examples and VIs make it easy to get up and running quickly. Our LabVIEW interface has the same API as our C API, which means that there are no islands of programmers at your facility. Your LabVIEW and C programming teams can exchange knowledge and experience seamlessly.

1. First, start by plugging a board into a chassis.

2. Now, power on the chassis hardware and open the LabVIEW example

3. If you go to Window> Show Block Diagram, you can see UEI VIs ready to go. In fact, there is a UEI tree which lists all the UEI VIs. Similarly, depending on the type of data you are wishing to acquire, you can use the session polymorphic VI pull down to configure different inputs or outputs

4. Run the LabVIEW example to begin communicating to the chassis, reading Synchro/Resolver position.

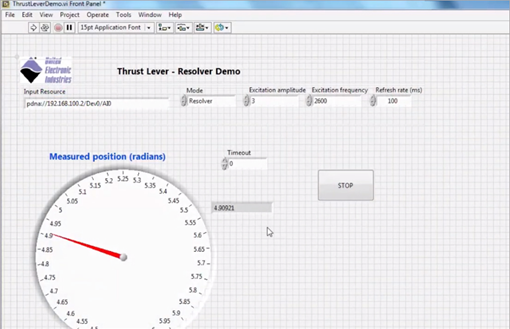

As you can see, there are simple drop downs which will allow you to configure your system to whatever specifications you would like; whether that be changing the data value you are recording or changing the method of acquiring such data.

Here is a demo of a throttle system in which the position of the throttle is being measured by the resolver and relayed into a LabVIEW application.