Thermal Bridging

Heat flow deviates from one-dimensional at corners, parapets, intersections between different assemblies, etc. When heat flows at a much higher rate through one part of an assembly than another, the term thermal bridge is used to reflect the fact that the heat has bridged over / around the thermal insulation. Thermal bridges become important when:

they cause cold spots within an assembly that might cause performance (e.g., surface condensation), durability or comfort problems

they are either large enough or intense enough (highly conductive) that they affect the total heat loss through the enclosure

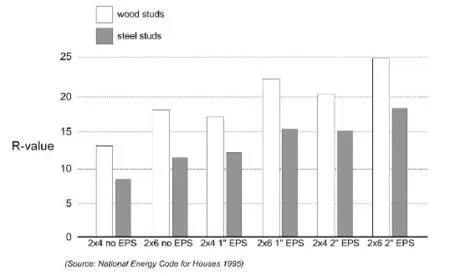

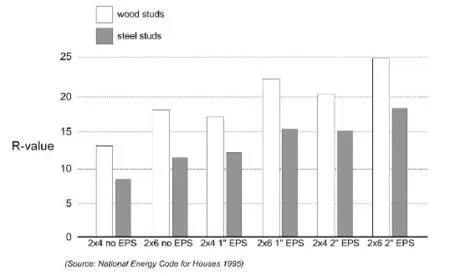

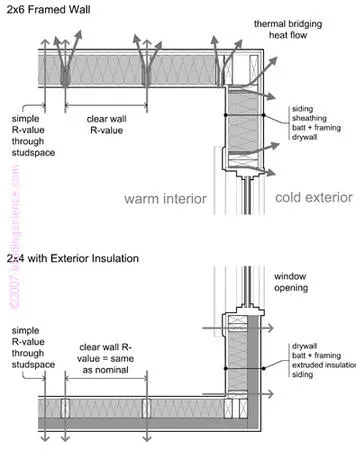

Thermal bridging can severely compromise thermal control and comfort in some building types. Heat flow through steel stud walls and metal curtainwalls is dominated by heat flow through the metal components. Failure to break these thermal bridges can reduce the R-value of the insulating components (the insulated glazing unit or batt insulation respectively) by 50 to 80%. Filling the voids in concrete block masonry with insulation is not very effective: adding R-15 insulation to a 12” block with increase the R-value of the wall by about R-2. Wood framed walls are not as badly affected, but reductions of 10 to 20% are common. A separate BSD discusses thermal bridging in more detail.

Figure 4: Best Case R-values for Walls with no extra framing for windows, floors or partitions.

Figure 5: Solving thermal bridging through studs by using insulating sheathing.