Important Gear Terminology in this picture :

Gear Terminology

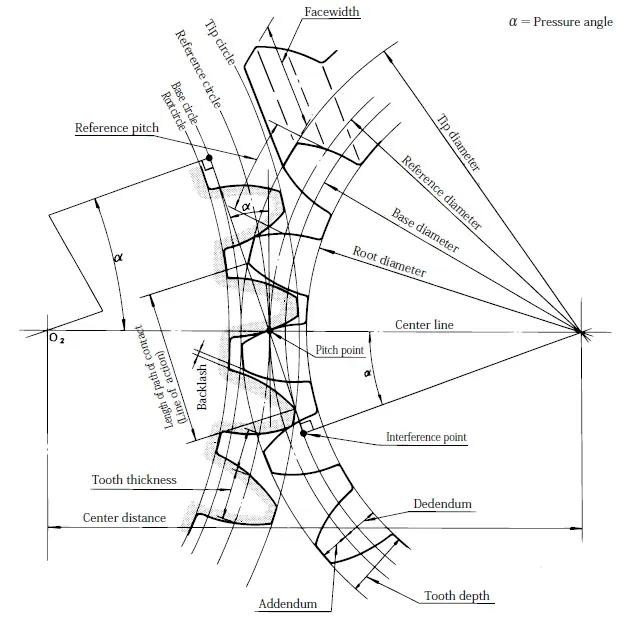

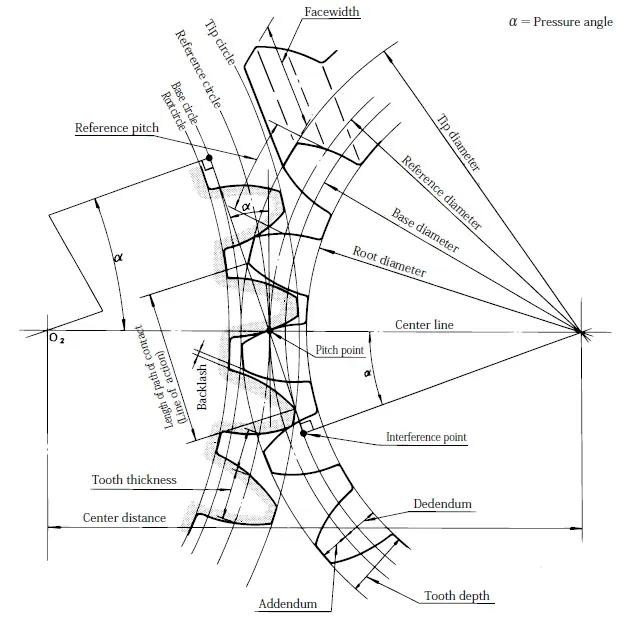

Important Gear Terminology in this picture :

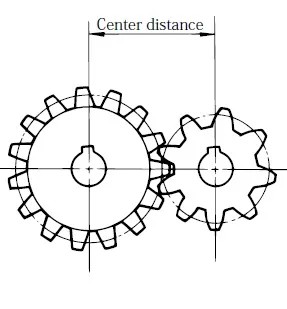

![]() Center distance

Center distance

![]() Length of path of contact (Line of action)

Length of path of contact (Line of action)

![]() Backlash

Backlash

![]() Interference point

Interference point

![]() Pitch point

Pitch point

![]() Reference pitch

Reference pitch

![]() Center line

Center line

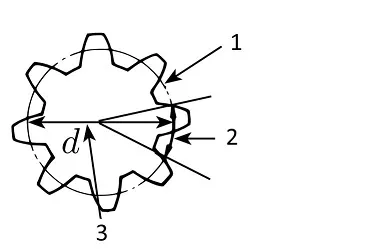

![]() Tip circle

Tip circle

![]() Base circle

Base circle

![]() Root circle

Root circle

![]() Tip diameter

Tip diameter

![]() Reference diameter

Reference diameter

![]() Base diameter

Base diameter

![]() Root diameter

Root diameter

![]() Pressure angle

Pressure angle

![]() Face width

Face width

![]() Tooth depth

Tooth depth

![]() Addendum

Addendum

![]() Dedendum

Dedendum

![]() Tooth thickness

Tooth thickness

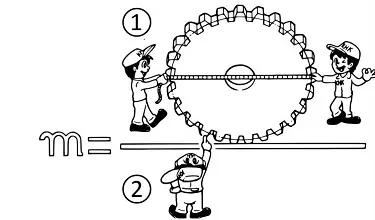

Gear Module

Module” is the unit of size that indicates how big or small a gear is. It is the ratio of the reference diameter of the gear divided by the number of teeth. Thus m = d/z (Module = Reference diameter/Number of teeth)

The mutual relation between the module and the reference diameter, etc. is as follows :

Reference diameter d = mz (Reference diameter = Module × Number of teeth)

Number of teeth z = d/m (Number of teeth = Reference diameter / Module)

Reference pitch p = πm (Reference pitch = π x module)

Then, what is the reference pitch ?

It is equal to the circumference divided by the number of teeth.

Reference pitch = Circumference (πd) / Number of teeth (z)

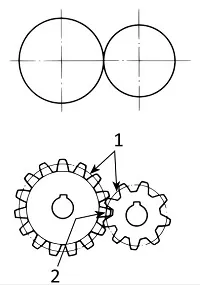

Then, what is the reference circle ?

Assume that there are two friction pulleys in contact whose diameters are equal to the reference diameters. As the surfaces are smooth, the rotation will not go properly when great force is applied. This problem will be solved if there are teeth on the periphery of the friction pulley. And this is the concept of gearing.

Summary

(1) The module describes the size of a gear.

(2) A pair of gears can only mesh correctly if and when the base pitch is the same.

Practicing What You’ve Learned

Spur Gear

Module m = 3

Pinion z1 = 15

Gear z2 = 55

Helical Gear

Module m = 3

Pinion z1 = 15

Gear z2 = 55

Helix angle β = 16º15′ / then cosβ = 0.96