Flat Belt

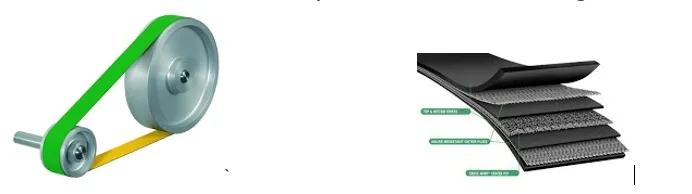

Flat belts are usually made of leather, rubber and fabric. belts made of leather has high coefficient of friction (can transmit more power) thereby ideal for flat belts. To achieve the desired thickness of belt, number of layers of belt material is cemented together.

`

Usually the top and bottom layers are made of leather or rubber which has high coefficient of friction and also it acts as a protective layer. The inside layers are made of canvas, fabric or other material which transmits the majority of the load handled by belt.

Number of plies in flat belts (ply)

A number of layers of belt material is cemented together to achieve the desired thickness of belt. The layer of belts is called as ply. The total number of belt layers used in a belt is called number of plies.

Properties of a flat belt material

![]() The efficiency of flat belts in 98%, which is equal to that of gears.

The efficiency of flat belts in 98%, which is equal to that of gears.

![]() They have high load carrying capacity.

They have high load carrying capacity.

![]() They can be employed where high operating speed is required.

They can be employed where high operating speed is required.

![]() They produce less noise compared to v-belts.

They produce less noise compared to v-belts.

![]() They can absorb shock loads compared to v-belts.

They can absorb shock loads compared to v-belts.

Flat Belt Selection - Using PSG Design Data Book

Step:1 Selection of standard pulley diameters

Calculate the diameters of the smaller and larger pulley using the relation

Then select the standard pulley diameters from PSG 7.54

|

|

Step:2 Calculation of design power

For calculating design power select,

Calculate the design power using the formula

| |

Step:3 Selection of belt

Select the type of belt from PSG 7.52 |

|

Step:4 Load Rating and Number of plies

Load Rating

Then calculate the load rating using the formula in PSG 7.54

Number of plies

| |

Step:5 Belt Width

Calculate the belt width using the formula

Select the standard belt width from PSG 7.52

| |

Step:6 Pulley Width

Calculate the pulley width using the condition in PSG 7.54

| |

Step:7 Length of Belt

Calculate the belt length using the condition in PSG 7.53 | |