The glass is made in Japan. Although the final product will look toward the future, the first steps call on glassmaking techniques of centuries past.

Craftsmen fill large handmade clay pots with one and a half tons of silica and boron oxide powders. The sandy mix goes into a great furnace, where it is heated for more than two days at temperatures as high as 1,500 degrees Celsius (2,732 Fahrenheit), melting the raw material until the 800-liter pots are brimming with molten glass. Over the course of 13 days, the material cools as the crystal-clear glass hardens uniformly, forming a structure that is resistant to heat and pressure.

The clay pots are then shattered with a sledgehammer, revealing the transparent monoliths within. Each slab weighs about a ton. The Ohara E6 glass is perhaps the purest optical glass in the world, known for its resistance to thermal expansion.

A slab of E6 glass.

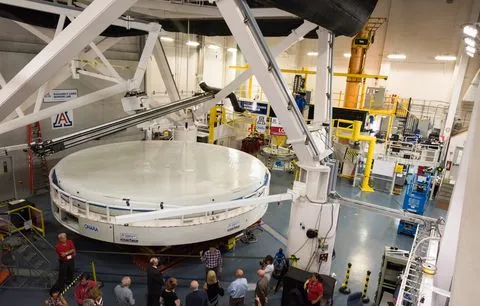

The Japanese glass is cut into smaller chunks that weigh four to five kilograms (9 to 11 lbs.) each, which are then shipped to Tucson, Arizona. Here, technicians will use the glass to cast gargantuan mirrors, each one spanning 8.4 meters in diameter—that's 27 feet from edge to edge—and weighing 17 tons. In time, seven of these segments will combine to form an enormous primary telescope mirror spanning 24.5 meters (80 feet) across.

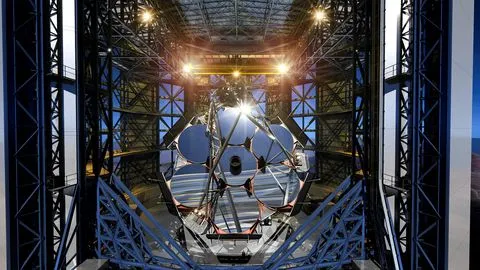

The justification for all this globetrotting, painstaking glass work is the Giant Magellan Telescope, which will become the largest optical telescope in the world. When complete in the mid-2020s, GMT will perch on the summit of Chile's Cerro Las Campanas at 8,200 feet, in a 22-story-tall building that is already under construction. Here, in the high altitudes of the Atacama Desert, the ultra-dry air offers some of the clearest views of the night sky anywhere on the planet.

The giant telescope will have 10 times the resolving power of the Hubble Space Telescope, revealing distant galaxies, the birth of stars, and the compositions of exoplanet atmospheres—a key field of research in the search for extraterrestrial life.

Artist rendering of the Giant Magellan Telescope.

GMTO

The beginning of telescope operations, known as first light, is planned for 2023 and will use just four mirrors. The first observations with all seven mirrors will follow in 2025. As for today: The pots are filled in Japan, the furnace is lit in Arizona, the ground is broken in Chile, and the Giant Magellan Telescope is under way.

"We had to make the first one before they let us make the second," says Dae Wook Kim, "because they didn't think it was possible to make such a potato chip."

Kim, an assistant professor at the College of Optical Sciences at the University of Arizona, has taken me deep into the bowels of telescope technology. We're standing in the Richard F. Caris Mirror Laboratory, a big bunker beneath the university's 55,000-seat football stadium. Here, below the gridiron of the Arizona Wildcats, is where the largest telescope mirrors in the world come together.

The Mirror Lab has "possibly the only people who can make large single mirrors anymore," says Patrick McCarthy, vice president for operations of the Giant Magellan Telescope Organization (GMTO). Arizona's lab has made mirrors for some of the most powerful telescopes on the planet, including the twin 6.5-meter mirrors for the Magellan Telescopes in Chile, the 8.4-meter ones for Arizona's Large Binocular Telescope (LBT), and the 8.4-meter mirror for the Large Synoptic Survey Telescope (LSST), an ambitious project to take 1,000 pairs of exposures of the night sky with a 3.8-gigapixel digital camera, the largest in the world.

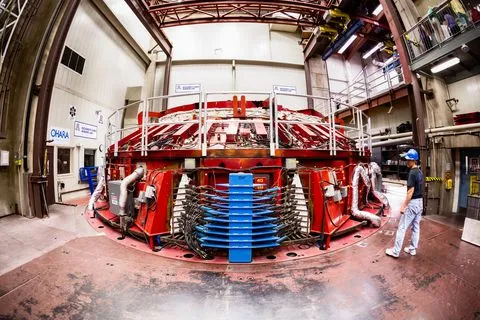

The glass for the 5th GMT mirror segment in the University of Arizona’s revolving furnace for spin-casting giant telescope mirrors, housed underneath the university football stadium.

At the moment, though, Kim is wrestling with his potato chip problem. The central mirror of the GMT will be a perfectly parabolic concave structure. The outer six segments, however, need to be shaped differently to work as a single primary mirror once aligned together. The six will circle the central mirror like flower petals, and each one needs to reflect the light it collects to the very center of the aperture, which means they must be ground to a potato chip shape.

The Mirror Lab houses a giant rotating furnace to cast the slabs of glass, equally enormous grinding and polishing machines, and a measuring tower to scan the mirrors with lasers. The whole process starts with the chunks of glass from Japan. Technicians fill the industrial merry-go-round furnace by hand. For the fifth mirror, they laid out precisely 17,481 kg (38,539 lbs.) of Ohara E6 glass.

The furnace begins to spin as the heat is cranked up to 700 C (1,292 F). The machine spins faster and grows hotter over the course of weeks, until the large rotating furnace hits 4.9 rpm and 1,165 C (2,129 F), hot enough to melt the glass blocks entirely.

The lab's secret is spin-casting mirrors in a rotating furnace over a mold to form a honeycomb structure, which makes their creations much lighter and sturdier than a mirror would be with no structural cells. The molten material pools around a mold of individual cells to create the honeycomb on the back, while a smooth surface of uninterrupted glass forms on the front.

The furnace then slows to 1/2 rpm for a three-month cooling process. The slow cooling of the glass allows it to anneal, relieving internal stresses and improving durability. Once the mirror cools and hardens, a year or perhaps longer of grinding and polishing can begin.

The rotating furnace at the Richard F. Caris Mirror Lab, loaded with Ohara E6 glass and about to start the casting process.

Despite all this telescope wizardry, the technicians at Arizona's Mirror Lab didn't know for sure if they'd be able to make something so precise as the potato chip. Grinding the shallow bowls into the saddle shape required for the outer GMT mirrors had never been attempted. "We don't get there in one shot," says Hubert M. "Buddy" Martin, an associate research professor of optical sciences at the University of Arizona.

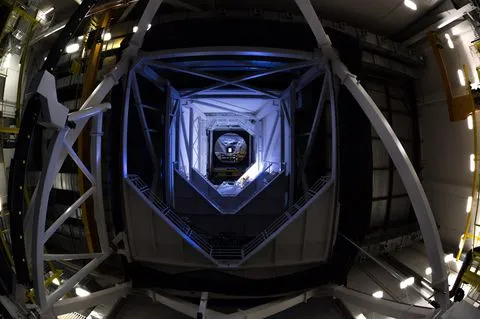

The mirrors are measured with lasers in a 28-meter-tall (92 feet) test tower. The tower is structurally isolated from the rest of the stadium. Three meters of solid concrete form its foundation, and pneumatic isolators prevent any vibrations from affecting the precision laser interferometer.

The test tower for measuring large telescope mirrors at the Mirror Lab.

"We're pretty much immune to vibrations in the building, football stadium, traffic outside, helicopters coming into the hospital," says Martin. "If we weren't isolated from these vibrations, they would wreak havoc on the measurements."

The test tower beams lasers down onto the mirror and collects the rebounding light with a series of sensors. The system creates a contour map of the glass surface. "You can think of it as a sheet of light designed to be the perfect mirror surface," Martin says. "When the light comes back you can see irregularities."

The test tower data feeds into computers that control an industrial grinder and a polisher. The grinder does quick work using 80-grit diamond sandpaper, a noisy process that requires hearing protection. The 35-inch-thick mirror is shaved down from 20 tons to more like 17.

Polishing, however, is a more delicate process. The Mirror Lab worked for a year and a half to polish the GMT's first mirror, moving the gargantuan slab of glass back and forth between the test tower and the polishing machine some 50 times. While the grinder works with a precision of about 75 micrometers, the polishing machine refines the glassy surface to perfection within 25 nanometers, less than a millionth of an inch.

Dr. Dae Wook Kim giving a tour of the Mirror Lab with mirror segment 2 under the test tower.

"If you made this mirror the entire size of the United States, the Rocky Mountains would be a coin width up," Kim says, standing before the enormous polishing machine. A rotating arm mounted to a control rig waxes a small part of the mirror, like a robotic gearhead meticulously polishing its '63 Sting Ray.

The polisher uses off-the-shelf Silly Putty that the Mirror Lab buys in 5-pound blocks. The MacGyver trick was Kim's idea, and it's an example of the inventive solutions you need in a one-of-a-kind mirror-casting lab. Despite all their advanced gadgets, the lab technicians use fishing wire to remove pads glued to the mirrors, and the furnace is loaded by hand.

Moving GMT mirror segment 4 out of the furnace with glue-on pads.

The first GMT mirror is now complete. It sits in a climate-controlled storage container on a trailer in Tucson, waiting to begin its journey to Chile. With one mirror in the basket, the Mirror Lab has been given the green light to cast more. There are four GMT mirrors in various stages of completion at the Arizona lab. The team hopes to make the potato chips faster now that the process has been proven.

At the Mirror Lab, you'll hear the technicians joke that they don't actually make mirrors. "We just make really huge pieces of glass," an employee said. The final step of the process—which will take place at the telescope's construction site in Chile—is coating the mirror blanks with a thin layer of aluminum to actually make them reflective.

The Giant Magellan Telescope inches toward first light, when these mirrors will turn to the heavens for the first time. "We want to take a picture of the universe when it was just being born," Kim says.