NON-INTERSECTING AND NON-PARALLEL (SKEW SHAFTS)

The following are the main types of gears connecting non- intersecting and non- parallel shafts.

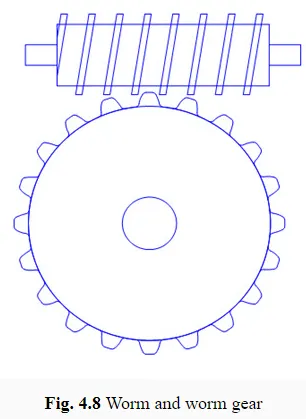

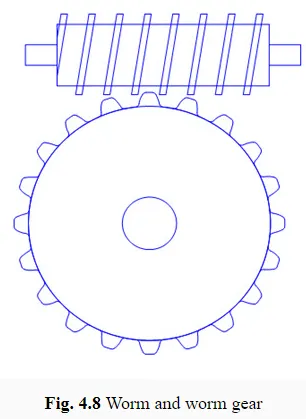

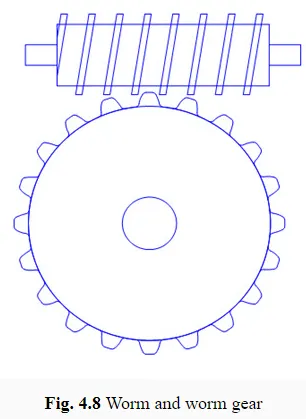

WORM AND WORM GEAR

The major function of worm gear is that of speed reduction. With the help of worm gears speed reductions greater than 300:1 can be achieved. Such types of gears are generally used in automobile steering mechanism.

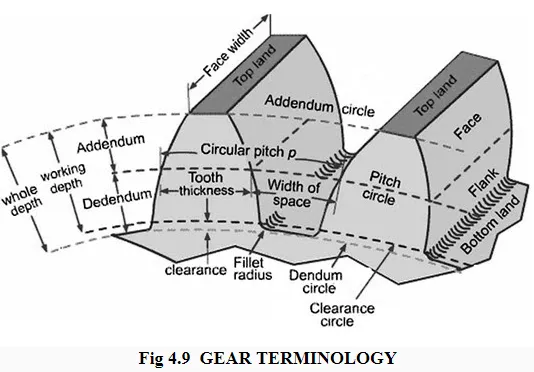

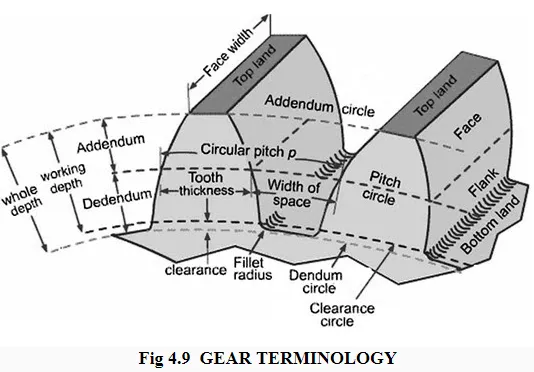

GEAR TERMINOLOGY

The Bureau of Indian standards (BIS) in their codes IS: 2458(1965) and IS: 2467(1965) has defined various parameters of gears as such:

· Pitch circle: It is theoretical circle which divides the gear into two imaginary parts addendum and dedendum

· Pitch circle diameter: it is also called PCD or bolt circle diameter. Pitch circle diameter as the name suggests is the diameter of pitch circle. Circular parts are assembled with other parts by passing bolts through holes drilled at PCD.

· Addendum: The vertical height along the circumference from the pitch circle to the gear top is called addendum.

· Addendum circle: it is an imaginary circle passing through top of gear.

· Dedendum: The vertical height along the circumference from the pitch circle to the bottom of gear is called Dedendum.

· Dedendum circle: it is an imaginary circle passing through bottom of gear.

· Clearance: The difference between the dedendum of one gear and the addendum of the mating gear.

· Face and Flank of a tooth: Axially the pitch circle divides the tooth in to two parts. The portion axially above the pitch circle is called face and below pitch circle is called flank.

· Tooth thickness: The thickness of the tooth along the pitch circle is called tooth thickness

· Tooth space: It is the distance between adjoining teeth of a gear.

· Fillet: A curvature called fillet is provided to connect tooth to the root circle

· Pitch point: Where two gears mesh their point of contact is called pitch point.

· Backlash: When gears mesh, there is clearance between the tooth of two mating gears. This clearance is referred to as backlash

· Pressure angle: The angle between the common normal at the point of tooth contact and the common tangent to the pitch circles. It refers to the angle through which forces are transmitted between meshing gears.

· Diametral pitch: The diametral pitch is the number of teeth divided by the pitch diameter.

· Module is defined as Pitch diameter divided by number of teeth.