Future developments in the automotive transmission system

1. The CVT will gradually replace the conventional automatic transmission due to its high fuel efficiency and smooth gear shift.

2. The technology of semi-automatic transmission systems will also be improved to perform smooth gear shift and extend the cars' lifetime, without losing fast acceleration and fuel efficiency.

3. The torque converter with fluid coupling may be improved, or may no longer be used for cars in the future due to its low-efficiency power transfer.

4. Auto Shift Manual Transmission – This transmission system combines the advantages of an automatic transmission with the flexibility and low fuel consumption of a manual transmission. This is an advanced Shift-By-Wire electronic control system technology. Shift-by-wire totally eliminates mechanical lever shifting, keeping both of driver's hands on the wheel.

The clutch is used only for starting and stopping. Once the vehicle is in motion, Auto Shift operates like an automatic transmission, with the efficiency of a manual transmission.

5. Adaptive transmission control - ATC has also been invented by using a computer to recognize and memorize different drivers' styles, and determining the best shifting timing for different drivers.

6. A transmission system is needed for a vehicle due to the internal combustion engines property of running at high pressure at high speed but low pressure at low speed. If someday an engine with different properties is invented, the transmission system may no longer be necessary, but can still get the vehicle to reach its maximum speed in a couple of seconds.

Continuously variable transmission

CVT is an “infinite speed” transmission which can change steplessly through an infinite number of effective gear ratios between maximum and minimum values. Unlike traditional automatic transmissions, continuously variable transmissions don't have a gearbox with a set number of gears, which means they don't have interlocking toothed wheels. The word gear in CVT refers to a ratio of engine shaft speed to driveshaft speed. Moreover, CVTs change this ratio without using a set of planetary gears.

Different types of CVTs –

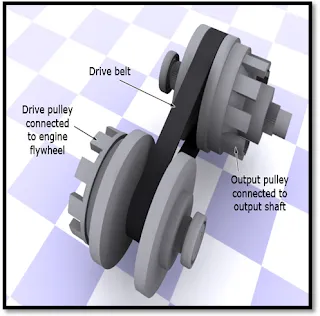

1. Pulley-based CVTs

2. Toroidal CVTs

3. Hydrostatic CVTs

The most common CVT design uses a segmented metal V-belt running between two pulleys. Each pulley consists of a pair of cones that can be moved close together or further apart to adjust the diameter at which the belt operates. The pulley ratios are electronically controlled to select the best overall drive ratio based on throttle position, vehicle speed and engine speed.