How does gear ratio affect torque

First....What is torque?:

Torque is a twisting force- (it doesn't do any 'work' itself- it is simple an application of energy).

Work (or 'stuff') happens, when torque is applied and movement occurs.

"Torque is a force that tends to rotate or turn things. You generate a torque any time you apply a force using a wrench. Tightening the lug nuts on your wheels is a good example. When you use a wrench, you apply a force to the handle. This force creates a torque on the lug nut, which tends to turn the lug nut.

English units of torque are pound-inches or pound-feet; the SI unit is the Newton-meter. Notice that the torque units contain a distance and a force. To calculate the torque, you just multiply the force by the distance from the center. In the case of lug nuts, if the wrench is a foot long, and you put 200 pounds of force on it, you are generating 200 pound-feet of torque. If you use a two-foot wrench, you only need to put 100 pounds of force on it to generate the same torque."

In summary:

Torque equals Force multiplied by Distance |

How does gear ratio affect Torque?

Simply put, torque at work (such as at a wheel) is your motor's torque times your gear ratio.

Motor Torque x gear ratio = torque at the wheel |

Lets say we have a 10rmps motor that is capable of 5 oz Torque (we know this from our motor spec.)

Lets say we have 2 gears. Our input gear (attached to our motor) has 10 teeth Our output gear has 50 teeth

Our Gear ratio is 5:1

Motor Torque x gear ratio = torque at the wheel

5oz x 5:1 = 25 oz

What if our gear ratio were 1:3 ?

5oz x 1:3 = 1.6oz

How does a gear ratio affect speed

The gear ratio tells us how fast one gear is rotating when compared to another.

If our input gear (10 teeth) is rotating at 5 rpms , and it is connected to our output gear (50 teeth), our output gear will rotate at 1 rpms.

Why?

Our gear ratio is 50:10... or 5:1

If our small gear rotates 1x, our large gear only rotates 1/5. It takes 5 rotations of our small gear to = 1 rotation of our large gear. Thus our large gear is rotating at 1/5 the speed = 1rmp.

What if our gear ratio where 1:3 ?

In this case our input gear is 3x larger as large as our output gear.

If our input gear were rotating at 20rmps.... each rotation, would result in 3 rotations of our output gear. Our output would be 60rpms.

Comparison between MacPherson double wishbone suspension system

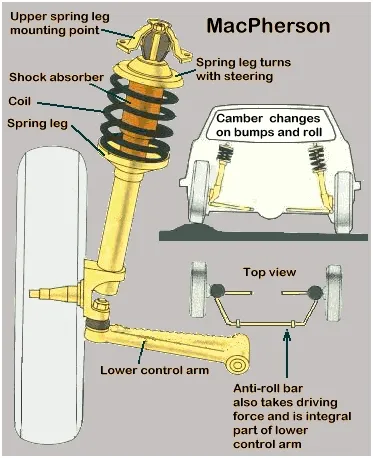

Two of the most popular suspensions systems for passenger cars today are the double wishbone suspension system and the MacPherson’s strut suspension system. While it is more usual to see the double wishbone system at the rear end of the car, MacPherson’s solution normally finds its place at the front end of the car. Both types of suspensions have their own sets of benefits and limitations, thus let us look at both the advantages and disadvantages of both systems, starting with the simpler of the two, the MacPherson struts.

MacPherson Struts- The struts are designed with more simplicity, and thus takes up less space horizontally. As a result, passengers get more compartment place in the car. They also display low un-sprung weight, an advantage that reduces the overall weight of the vehicle as well as increases the car’s acceleration. Lower un-sprung weight also makes your ride more comfortable. Another major advantage of this system is its ease of manufacturing as well as low cost of manufacture compared to other stand-alone suspension systems. Without an upper arm, the suspension system designers can directly block vibration from reaching the passenger compartment.

Nevertheless, the MacPherson struts come with their own drawbacks. Being a long, vertical assembly, you would encounter difficulties if you lower your car as they may be collision with the structure of your car. Thus they do not work well with racing cars that are normally lowered. The MacPherson struts also have problems working with wider wheels that have increased scrub radius, where you would need extra effort to navigate your car in this situation. There is also the problem with the small camber change with vertical movement of the suspension, which could mean the tires have less contact with the road during cornering. This could reduce handling abilities of your vehicle.

Double Wishbone Suspension System- One of its primary benefits is the increase of negative chamber as a result of the vertical suspension movement of the upper and lower arms. This translates to better stability properties for the car as the tires on the outside maintain more contact with the road surface. Handling performance also increases. The double suspension system is much more rigid and stable than other suspension systems, thus you would realize that your steering and wheel alignments are constant even when undergoing high amounts of stress.

Moving on to the drawbacks of the double wishbone suspension system, it is normally bugged by cost issues as it is a more complicated design to produce. There are many parts to the system, and thus every time any of these malfunction of fail, your whole system fails. Repair, modification and maintenance costs and complexities for double wishbone suspension systems are normally higher due to these reasons. This suspension system also proves to be flexible for design engineers, as the arms of the system can be fixed at different angles to the surface, parameters such as camber gain, roll center height and swing arm length can be determined and designed flexibly to suit and road surface in condition.

As we have seen, both suspension systems have their own plus points and limitations. To conclude, double wishbones may perform better, but the MacPherson struts would prove to be more affordable in the long run.