To properly operate, a mechanical watch needs power. But power also needs to be stored and delivered in the most efficient way to make the watch runs accurately. But how does a watch deliver and regulate energy throughout its mechanism?! What is the “escapement” ? Let’s find out here !

As we’ve seen in the article about power-reserve, the watch can store energy thanks to its mainspring. But then, it has to be delivered to the balance spring in the most efficient way to 1, do not waste energy and 2, use it properly.

The escapement:

This is the first thing you need to know: the energy of the mainspring is delivered into the watch mechanism thanks to the escapement. This watch component will have impact on your power reserve and onto your watch accuracy. But it’s not the escapement that makes your watch accurate! The precision is the result of the balance spring (which gives the famous “tic tac” noise we all know).

The escapement is indeed the link between the energy released by the mainspring and the regulating organ: the balance spring.

Traditionally, the lever escapement is used throughout watchmaking. It is both the easiest to make, and one of the most efficient. On the first scheme the lever is the light blue component with two rubies. This anchor-style lever is fixed on a pivot and rotates at each movement of the oscilating spring (“tic tac”) which release the mainspring energy and make the third wheel rotate. This overall idea will operate until there is no more energy inside the mainspring. Then the anchor will stop (blocked by the third wheel) and the balance spring won’t be able to rotate anymore.

This scheme looks really efficient, however it has two drawbacks: the energy powered by the mainspring is too high when fully wound and then too low when almost unwound.

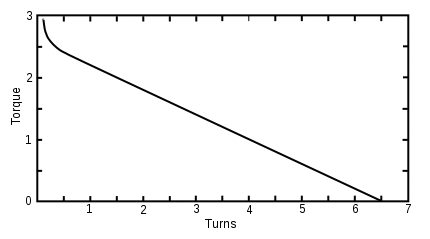

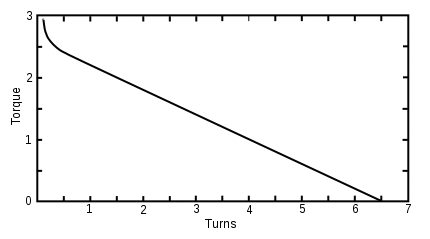

As we see on this graphic, the torque delivered from the mainspring is not constant throughout its lifetime. The x-axe is the torque power and the y-axe is the number of turns the mainspring is doing inside its barrel. This is also why we advise you to wind-up your watch on a daily basis, to deliver the same energy everyday to the watch (and to maximise the torque power).

Also, as you remember, the holy grail of a watchmaker is precision! With this traditional lever escapement, the force given to the balance spring is not constant and can cause some imprecisions. Therefore watchmakers have worked on different escapement devices, resulting in constant-force mechanisms.

Constant-force mechanisms:

The overall idea of this kind of mechanism is to deliver steady supply of energy onto the escapement, despite the torque fluctuation of the mainspring.

Back in the 15th century, watchmakers have already tried to solve the problem by creating what was called a “remontoir d’égalité”. Nowadays, François-Paul Journe is famous for this kind of mechanism. The process is to put an intermediary component in between the mainspring and the lever escapement. This component (in Journe’s watches for example) is a small spring, which delivers each time it is fully armed by the mainspring, the same amount of energy to the escapement. As the escapement receives more steady energy, the balance spring is less subject to torque variation and is therefore more precise. Your watch will stay more accurate! I guess it’s time for you to check the accuracy of your watch on Toolwatch.io. You will figure out if your watch is still operating well or not .

Back to constant-force mechanisms! That was one (but great!) solution. Other exists such as the Girard Perregaux constant-force one released in 2013. This one does not requires a small spring in between the mainspring and the escapement, because they have created a new escapement which regulates itself the power it receives! Here the escapement has been totally rebuilt to integrate a 14 micron silicon buckled-blade which jumps from a position A to a position B when it has received enough power. This jump releases the exact same force to the mechanism.

Last but not least, the Fusee Chain transmission.

This mechanism was also first invented in the15th century. It focuses on resolving the source of the problem: the torque variation of the mainspring. The idea is to get a chain wrapped around a cone-shape fusee and attached to the mainspring barrel. Then as the mainspring unwinds, the chain also unwinds from the fusee with a constant torque thanks to its shape. The gearwheels are therefore supplied with a constant force and the escapement can properly operates.

The fusee-chain transmission has been used a lot in Marine chronometer.

You can see below an example of fusee-chain mechanism: