Ratchets are mechanisms that serve to limit either rotary or linear motion to only one direction. Ratchet designs vary but the basic composition of parts is fairly universal.

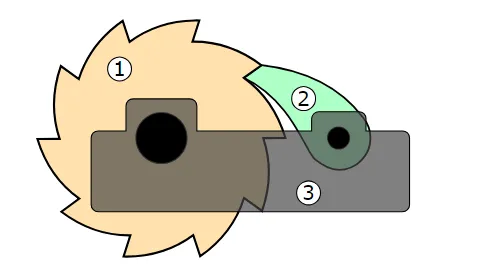

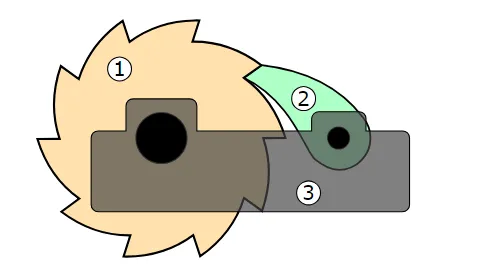

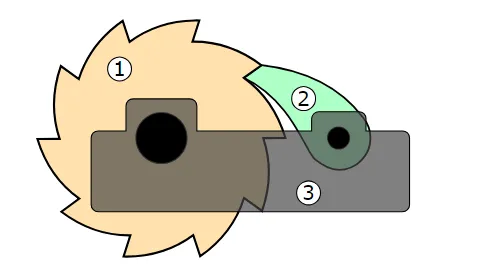

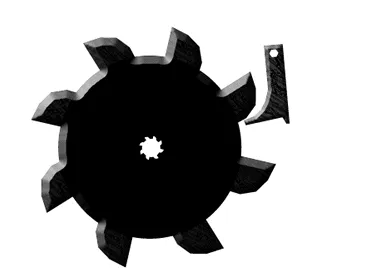

Figure 1. "Ratchet Drawing"

A ratchet is composed of three main parts: a round gear (or a linear rack), a pawl (also called a "click"), and a base (or mount).

There may be additional and distinct parts that make up a particular ratchet device. In both types of ratchet describe above, a force is often applied to the pawl in order to maintain contact with the gear. Springs or a lever system are usually used to accomplish this. Lever systems involve turning the pawl into a first order lever (see our page on levers for more on the topic). In this capacity the pawl rotates into a position where it engages the gear. This type of design can be used to create a mechanism where the direction of the restricted motion can be changed.

1 . Ratchet (Gear):

2 . Ratchet (Linear Rack):

The geometry of the gear or rack is usually designed with a ramp feature on one side of the tooth leading to a sharp drop off which restricts motion of the pawl when the linear or rotational direction is reversed. Most ratchet mechanisms are not very large as only a small vertical wall is needed to prevent motion in one direction. However, in applications that feature substantial forces, consideration needs to be given to material selection, thickness, and overall design in order to sufficiently support those forces.

Figure 2. General Gear Ratchet Mechanism

Ratchets can serve as a useful mechanism in many different applications.

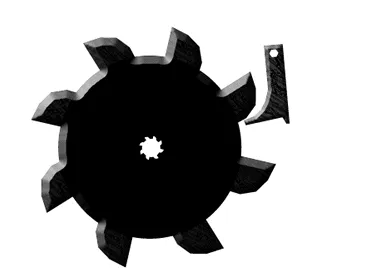

Figure 3. Ratchet Example: Socket Wrench

Figure 4. Ratchet Example: Turnstile

Figure 5. Ratchet Example: Zip Tie

Figure 6. Ratchet Example: Ratchet Straps

Ratchets can only stop backward motion at discrete locations (i.e. at each successive gear). As a consequence ratchets can allow a limited amount of backward motion called backlash or "play." Backlash is the maximum amount of distance or the largest angle of rotation that can be lost in one direction (typically the direction opposite that in which the device is designed to move freely) prior to a resistive force being applied to the next part (tooth) in the mechanical sequence. If a design requires one to minimize play in the device, it is possible to make a toothless ratchet utilizing two high friction surfaces (e.g. metal and rubber). Since backlash is principally a function of the surface's compressibility, something like a rubber surface can significantly reduce losses due to backlash.