Actuators are devices that convert some type of stored energy into motion. The stored energy is usually in the form of compressed air (pneumatic pressure), electrical potential, or liquid (hydraulic) pressure. It is typically stored within a sealed cylinder made in most cases from metal.

Actuators that utilize compressed air are referred to as pneumatic actuators or pneumatic cylinders. Many types of pneumatic actuators exist that can produce either rotary or linear motion. These mechanisms primarily consist of a piston sealed within a cylinder and valves to control the flow of compressed air into the cylinder. Pneumatic cylinders can be single or double acting actuators.

a. Single acting pneumatic actuators use compressed air to create motion in one direction. A spring serves to return the piston to its original position.

Figure 1. Single Acting Pneumatic Actuator

The force exerted by a single acting pneumatic cylinder can be found using the following equation:

b. Double acting actuators use compressed air to create motion in both directions. Since double acting pistons can have pressure on both sides of the piston, the force applied in the direction of motion is the difference between the forces created by the two pressures.

Figure 2. Double Acting Pneumatic Actuator

Typically, only one side of the cylinder is pressurized at a time, while the other remains unpressurized. The force produced on the rod side of the piston is calculated using the equation below:

Where:

F is the force

P is the pressure on the rod side

d2 is the piston diameter

d1 is the rod diameter

The force acting on the other side (without a rod) of the piston can be calculated using the same equation used for single acting actuators.

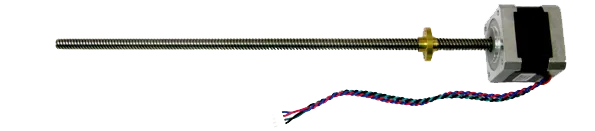

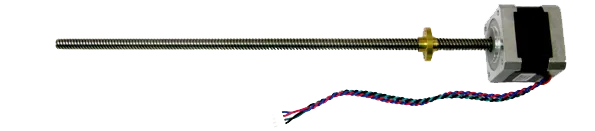

Electric actuators used to create linear or rotary motion are usually comprised of an electric motor and a control system which converts electrical energy into torque. These mechanisms can be used to create very precise movements. For example, the rotary motion of an electric motor can be used to create precise linear motion through the use of a screw and nut assembly within a fixed housing. The motor rotates a screw within the housing causing the nut to move linearly along the threads.

Figure 3. Electric Linear Actuator

Hydraulic cylinders are based on the principle (and assumption) that fluids are incompressible, meaning that the volume of the fluid cannot be changed, regardless of how much pressure is applied to the fluid. These mechanisms usually consist of two pistons in separate cylinders where the hydraulic fluid can travel from one cylinder to the other. When a force is applied to one of the pistons, the force is transmitted through the fluid to the other piston.

Figure 3. Hydraulic Actuators (often found on construction equipment)

Design Considerations For Hydraulic Actuators: A mechanical advantage can be achieved by changing the diameter of the two pistons. The force can be magnified if the diameter of the output piston is larger than the diameter of the input piston (in which case the distance in which the output piston travels will be less than the travel of the input piston). Since we can assume the fluid is incompressible, we know this type of system can be mathematically represented by the following equation:

Where:

Fin is the input force,

Fout is the output force,

Ain is the area of the input piston, and

Aout is the area of the output piston

Hydraulic actuators can also be double acting through the use of a pump that provides the input force and a valve system that controls which side of the piston the fluid is pumped into.