INTERMITTENT ROTARY MOTION

The Geneva wheel, or Maltese cross, is a camlike mechanism that provides intermittent rotary motion and is widely used in both low-speed and high-speed machinery. Although originally developed as a stop to prevent over winding of watches, it is now used extensively in automatic machinery, for example, where a spindle, turret, or worktable must be indexed. It is also used in motion-picture projectors to provide the intermittent advance of the film.

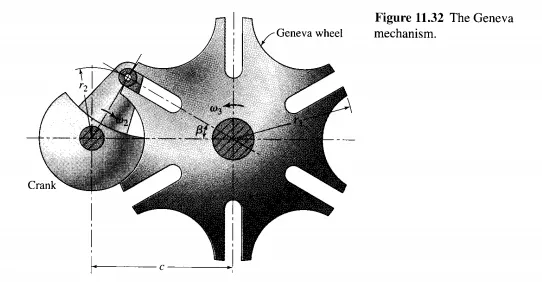

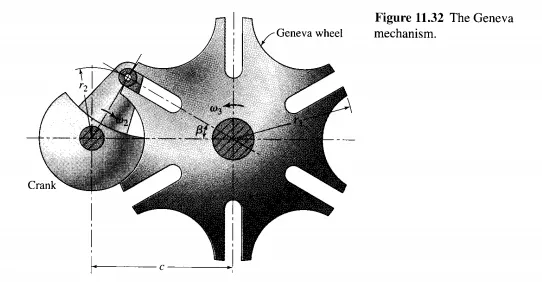

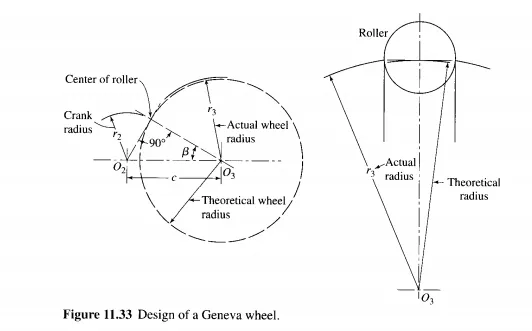

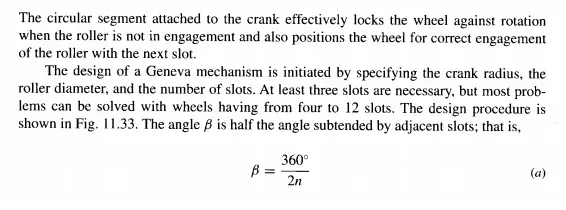

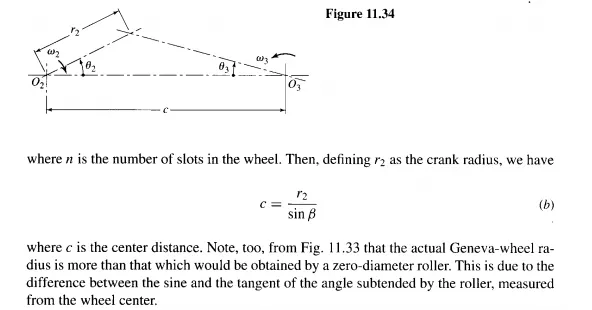

A drawing of a six-slot Geneva mechanism is shown in Fig. 11.32. Notice that the centerlines of the slot and crank are mutually perpendicular at engagement and at disengagement. The crank, which usually rotates at a uniform angular velocity, carries a roller to engage with the slots. During one revolution of the crank the Geneva wheel rotates a fractional part of a revolution, the amount of which is dependent upon the number of slots.

Several methods have been employed to reduce the wheel acceleration in order to reduce inertia forces and the consequent wear on the sides of the slot. Among these is the idea of using a curved slot. This can reduce the acceleration, but also increases the deceleration and consequently the wear on the other side of the slot.

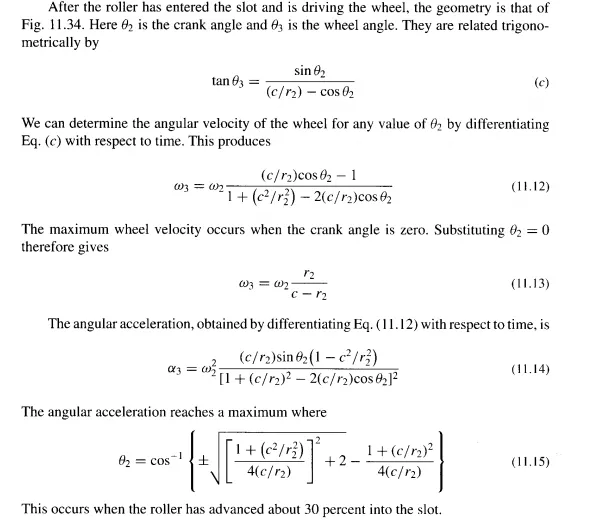

Another method uses the Hrones-Nelson atlas for synthesis. The idea is to place the roller on the connecting link of a four-bar linkage. During the period in which it drives the wheel, the path of the roller should be curved and should have a low value of acceleration. Figure 11.35 shows one solution and includes the path taken by the roller. This is the path that is sought while leafing through the book.

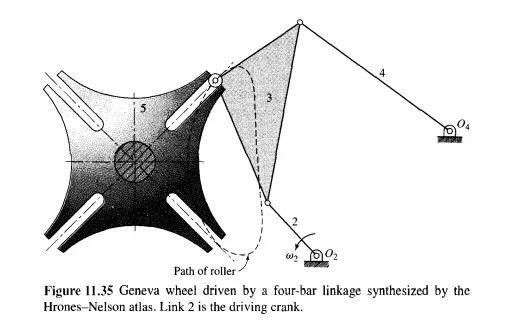

The inverse Geneva mechanism of Fig. 11.36 enables the wheel to rotate in the same direction as the crank and requires less radial space. The locking device is not shown, but

this can be a circular segment attached to the crank, as before, which locks by wiping against a built-up rim on the periphery of the wheel.