Worms and Worm Gears

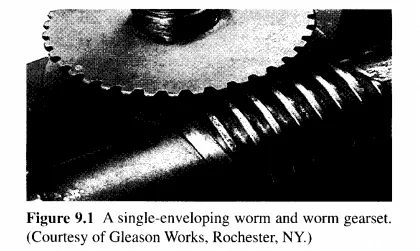

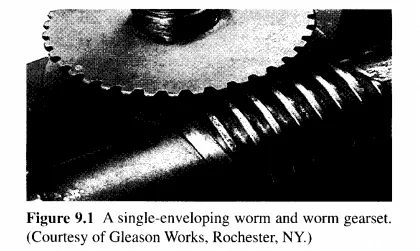

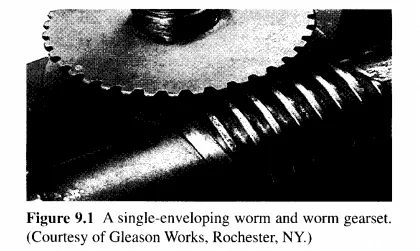

A worm is a machine member having a screw-like thread, and worm teeth are frequently spoken of as threads. A worm meshes with a conjugate gear-like member called a worm wheel or a worm gear. Figure 9.1 shows a worm and worm gear in an application. These gears are used with nonintersecting shafts that are usually at a shaft angle of 90°, but there is no reason why shaft angles other than 90° cannot be used if a design demands it.

Worms in common use have from one to four teeth and are said to be single-threaded, double-threaded, and so on. As we will see, there is no definite relation between the number of teeth and the pitch diameter of a worm. The number of teeth on a worm gear is usually much higher and, therefore, the angular velocity of the worm gear is usually much lower than that of the worm. In fact, often, one primary type of application for a worm and worm gear is in order to obtain a very large angular velocity reduction-that is, a very low first-order kinematic coefficient or angular velocity ratio. In keeping with the low velocity ratio, the worm gear is usually the driven member of the pair and the worm is usually the driving member.

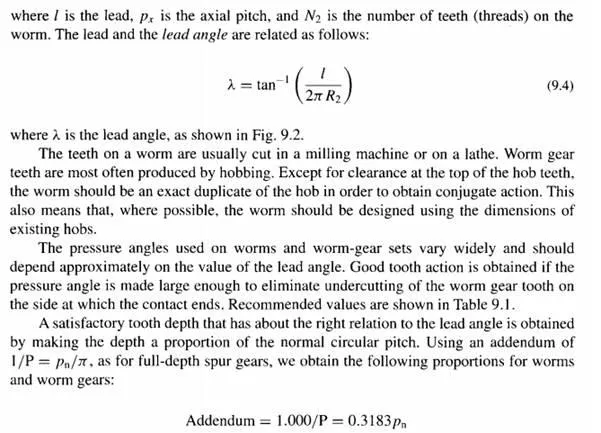

A worm gear, unlike a spur or helical gear, has a face that is made concave so that it partially wraps around, or envelops, the worm, as shown in Fig. 9.2. Worms are sometimes designed with a cylindrical pitch surface, or they may have an hourglass shape, such that the worm also wraps around or partially encloses the worm gear. If the enveloping worm gear is mated with a cylindrical worm, the set is said to be single-enveloping. When the worm is hourglass-shaped, the worm and worm gearset is said to be double-enveloping because each member partially wraps around the other; such a worm is sometimes called a Hindley worm. The nomenclature of a single-enveloping worm and worm gearset is shown in Fig. 9.2.

Figure 9.2 Nomenclature of a single-enveloping worm and worm gearset.

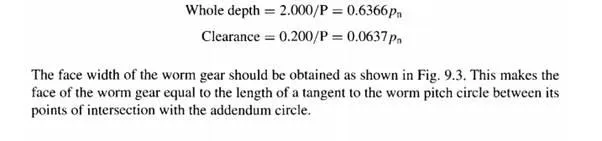

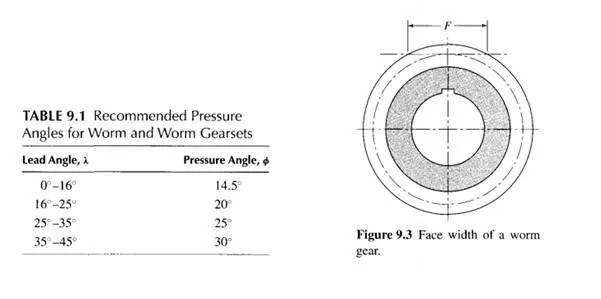

A worm and worm gear combination is similar to a pair of mating crossed-helical gears except that the worm gear partially envelops the worm. For this reason they have line contact instead of the point contact found in crossed-helical gears and are thus able to transmit more power. When a double-enveloping worm and worm gearset is used, even more power can be transmitted, at least in theory, because contact is distributed over an area on the tooth surfaces.