Parallel-Axis Helical Gears

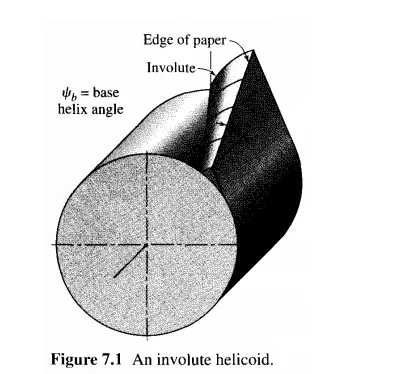

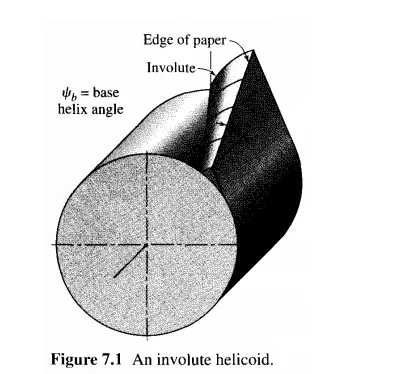

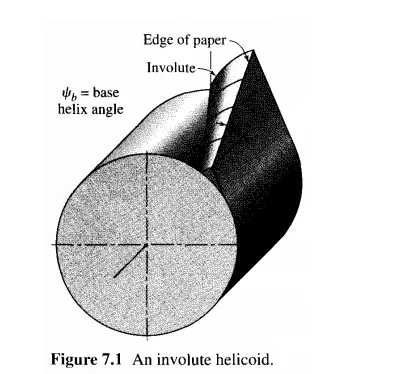

The shape of the tooth of a helical gear is illustrated in Fig. 7.1. If a piece of paper is cut into the shape of a parallelogram and wrapped around a cylinder, the angular edge of the paper wraps into a helix. The cylinder plays the same role as the base cylinder of Chapter 6. If the paper is then unwound, each point on the angular edge generates an involute curve as was shown in Section 6.3 for spur gears. The surface obtained when every point on the angular edge of the paper generates an involute is called an involute helicoid. If we imagine the strip of paper as unwrapping from a base cylinder on one gear and wrapping up onto the base cylinder of another, then a line on this strip of paper generates two involute helicoids meshing as two tangent tooth shapes. The initial contact of spur gear teeth, as we saw in the previous chapter, is a line extending across the face of the tooth.

The initial contact of helical gear teeth starts as a point and changes into a line as the teeth come into more engagement; in helical gears, however, the line is diagonal across the face of the tooth. It is this gradual engagement of the teeth and the smooth transfer of load from one tooth to another that give helical gears the ability to quietly transmit heavy loads at high speeds.

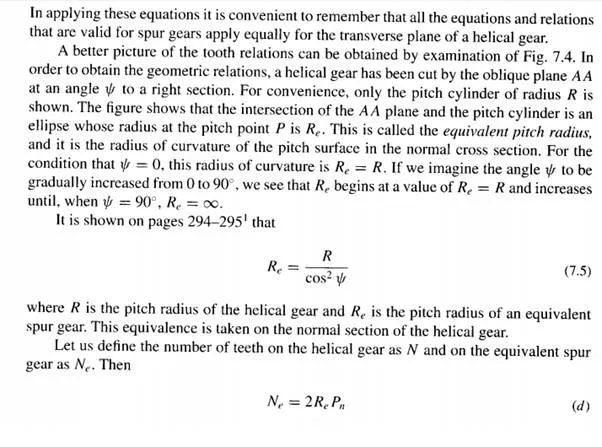

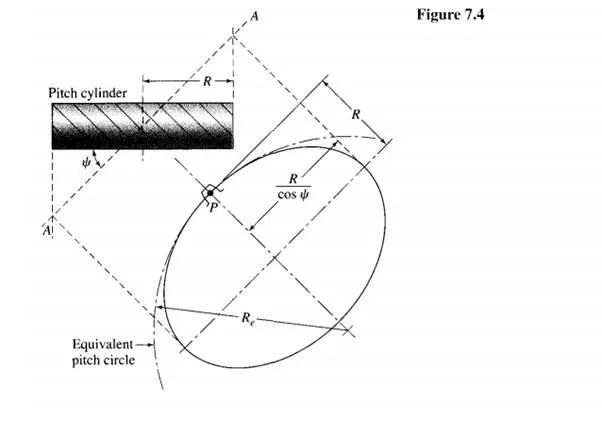

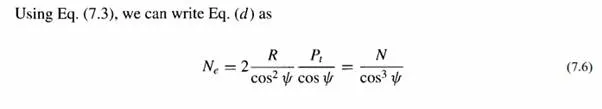

Helical Gear tooth Relations