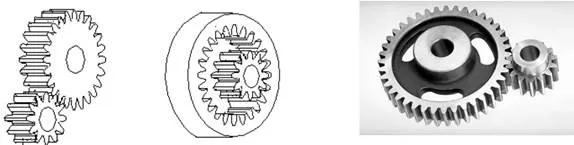

Gears for connecting parallel shafts

1. Spur gears: Spur gears are the most common type of gears. They have straight teeth, and are mounted on parallel shafts. Sometimes, many spur gears are used at once to create very large gear reductions. Each time a gear tooth engages a tooth on the other gear, the teeth collide, and this impact makes a noise. It also increases the stress on the gear teeth. To reduce the noise and stress in the gears, most of the gears in your car are

|

| Internal contact |

External contact |

| |

|

|

|

Spur gears

Spur gears are the most commonly used gear type. They are characterized by teeth, which are perpendicular to the face of the gear. Spur gears are most commonly available, and are generally the least expensive.

ü Limitations: Spur gears generally cannot be used when a direction change between the two shafts is required.

ü Advantages: Spur gears are easy to find, inexpensive, and efficient.

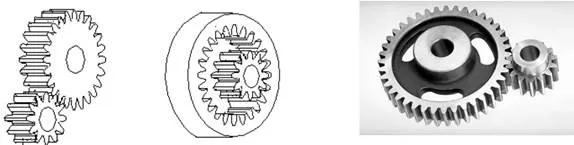

2. Parallel helical gears: The teeth on helical gears are cut at an angle to the face of the gear. When two teeth on a helical gear system engage, the contact starts at one end of the tooth and gradually spreads as the gears rotate, until the two teeth are in full engagement.

Helical gears

Herringbone gears

(or double-helical gears)

This gradual engagement makes helical gears operate much more smoothly and quietly than spur gears. For this reason, helical gears are used in almost all car transmission.

Because of the angle of the teeth on helical gears, they create a thrust load on the gear when they mesh. Devices that use helical gears have bearings that can support this thrust load.

One interesting thing about helical gears is that if the angles of the gear teeth are correct, they can be mounted on perpendicular shafts, adjusting the rotation angle by 90 degrees.

Helical gears to have the following differences from spur gears of the same size:

· Tooth strength is greater because the teeth are longer,

· Greater surface contact on the teeth allows a helical gear to carry more load than a spur gear

· The longer surface of contact reduces the efficiency of a helical gear relative to a spur gear

Rack and pinion: (The rack is like a gear whose axis is at infinity mathematically but practically a gear of larger length.)

Racks are straight gears that are used to convert rotational motion to translational motion by means of a gear mesh. (They are in theory a gear with an infinite pitch diameter). In theory, the torque and angular velocity of the pinion

gear are related to the Force and the velocity of the rack by the radius of the pinion gear, as is shown.

Perhaps the most well-known application of a rack is the rack and pinion steering system used on many cars in the past.