Bench mark (BM)

In order to make OD accessible to all users throughout the country, a series of permanent marks were established, called bench marks. The height of these marks relative to OD has been established by differential levelling and until about 1970 was regularly checked for any change in elevation.

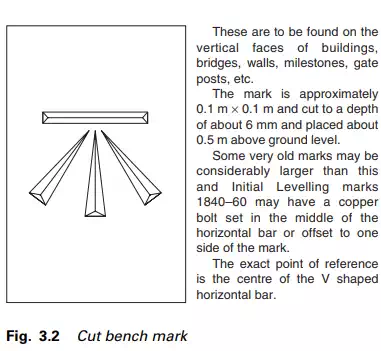

(1) Cut bench marks

The cut bench mark is the most common type of BM and is usually cut into the vertical surface of a stable structure (Figure 3.2).

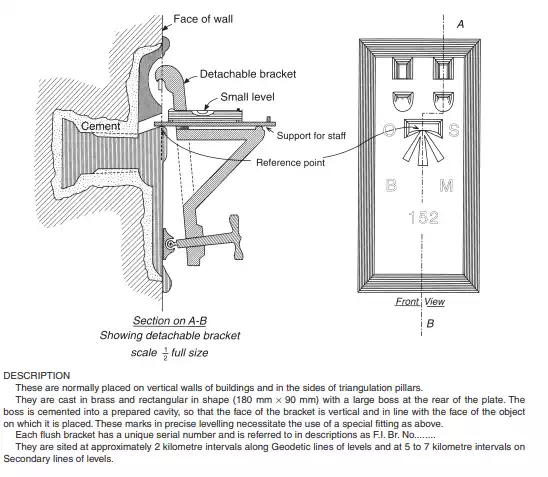

(2) Flush brackets

Flush brackets are metal plates, 180 mm ◊ 90 mm, cemented into the face of buildings and were established at intervals of about 2 km (Figure 3.3).

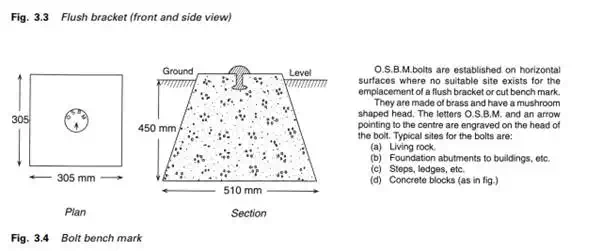

†(3) Bolt bench marks

Bolt bench marks are 60-mm-diameter brass bolts set in horizontal surfaces and engraved with an arrow and the letters OSBM (Figure 3.4).

(4) Fundamental bench marks (FBM)

In the UK, FBMs were established by precise geodetic levelling, at intervals of about 50 km. Each mark consists of a buried chamber containing two reference points, whilst the published elevation is to a brass bolt on the top of a concrete pillar (Figure 3.5).

Rivet and pivot BMs are also to be found in horizontal surfaces. Details of BMs within the individualís area of interest may be obtained in the form of a Bench Mark List from the OS. Their location and value are currently also shown on OS plans at the 1/2500 and 1/1250 scales. Their values are quoted as precise to the nearest 12 mm relative to neighbouring bench marks at the time of the original observation only.

Bench marks established by individuals, other than the OS, such as engineers for construction work, are called temporary bench marks (TBM)