So, what is operations and supply chain management?

The term “supply chain management” was coined by Keith Oliver, a leading British logistician who first mentioned this concept in an interview with Financial Times in 1982.

According to Oliver, “Supply chain management (SCM) is the process of planning, implementing, and controlling the operations of a supply chain with the purpose to satisfy customer requirements as efficiently as possible. Supply chain management spans all movement and storage of raw materials, work-in-process inventory, and finished goods from point-of-origin to point of consumption.”

Since then, multiple experts have offered their own definitions of SCM. But in a nutshell, it can be described as supervising the whole flow of goods and services, from raw materials to final products, “from farm to fork.”

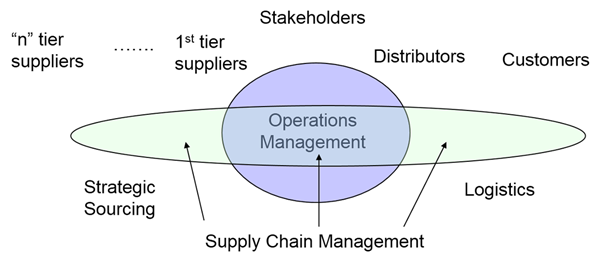

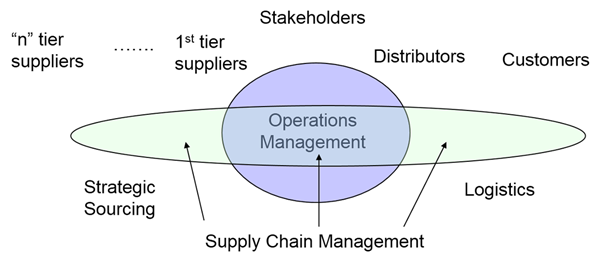

SCM is tightly interwoven with operations management (OM), that focuses on coordinating and optimizing the internal processes, whether it be designing and manufacturing goods or developing services. To put it simply, both SCM and OM take care of the same product, but at different stages of its lifecycle.

There are several areas where SCM and OM functions can overlap. But basically, SCM is in charge of outside interactions — with suppliers, warehouses, distributors, and end-customers, while OM supervises everything that happens inside the company.

Small companies often don’t separate the external and internal parts of product flow, so that the same specialist or department controls all phases goods and services pass through en route to the end customer. Large organizations usually split responsibilities between two executives — a supply chain manager and an operations manager.

What are the roles of a supply chain manager and operations manager?

The top objective of both experts is to save expenses and boost efficiency of production without compromising on quality. But while a supply chain manager focuses on external processes, an operations manager solves pressing internal tasks. The former negotiates terms with third-party contractors (suppliers, logistics teams, distributors) and optimizes movement of materials and goods from one point to another outside the organization. The latter communicates with stakeholders and implements policies to boost manufacturing and get things working well inside the company.

Given that both pursue the same global goal and work on the same product, they have some overlapping responsibilities. For example, both are involved in:

Supply chain and operations managers constantly exchange knowledge and information. Together, they reveal new opportunities for the company and address them. Within this ambitious aim, they take part in choosing innovative technologies that will reduce manual operations and automate stages of product flow.