Innovating supply chain management operations

An important question to ask about business process automation is “How many steps can be delegated to technologies?” In the case of a supply chain network, the answer will depend on its length and the number of operations involved.

The Institute for Supply Management (ISM), the world’s oldest and largest association in the field, differentiates 14 essential components of the supply chain that can vary depending on product complexity as well as business size and type (manufacturer, distributor, retailer). We’ll focus on the most common components and on how software solutions can transform and streamline crucial SCM processes.

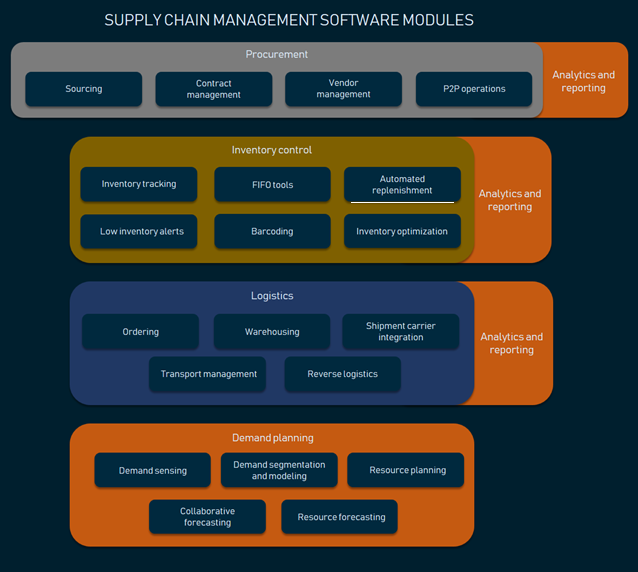

A brief overview of the main supply chain management modules

Procurement

Procurement, or obtaining materials, goods, and services you need to run your business is the very first element of a supply chain.

The procurement cycle involves multiple steps — analyzing and selecting vendors, negotiating terms, ordering, and invoicing, to name a few. The significant part of these procedures can be delegated to procurement management software. This will speed up the workflow, enhance transparency, save time, and, finally, reduce costs, a key priority for 78 percent of procurement leaders.

The core functionality of procurement software covers the following areas.

Contract management. Among other things, the digital “administrator” helps you create and standardize contract templates, boosts approval processes, and captures electronic signatures.

Procure-to-pay (P2P) operations. P2P is a subdivision of procurement that covers financial transactions. The set of P2P features differs from product to product. But the core functionality usually boils down to managing a purchase requisition process, generating and tracking purchase orders (POs), and invoice matching. The system compares invoices to the corresponding POs to eliminate mistakes and duplications. If there are any deviations, the invoices are sent back to the supplier for corrections. Otherwise, payment is authorized.

Vendor (supplier) management. An app aggregates all data about your vendors, updates it, and alerts about expired qualifications and assessments. The performance of suppliers is measured against critical metrics such as speed, accuracy, quality, and price.

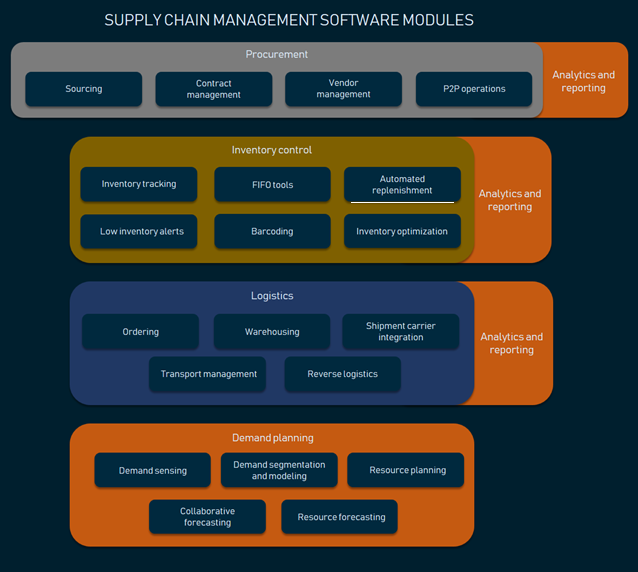

A VMS dashboard gives you a big picture of all supplier-related data and activities.

Spend analytics. The automated collecting, classifying, and analyzing of expenditure data brings visibility to the complex procurement process and allows businesses to discover savings opportunities.

Inventory control

Inventory can be defined as all goods and materials a company keeps on hand to meet customer demand. There are four major categories of inventory:

In an ideal world, the first three categories of items would move through the supply chain without stops and bottlenecks, ensuring a rapid investment payback. In reality, supply is rarely (or rather never) equal to demand, with inventory expenses amounting to a substantial 45-90 percent of the company’s total budget. The costs of excess stock can be huge, tying up company funds and reducing cash flow.

Inventory control aims at finding and maintaining the perfect balance between holding too much stock and running out of it across all supply chain nodes. This complex task requires the coordinated effort of different departments. As the business grows, it becomes harder to manage multiple separate subdivisions manually.

The adoption of specialized systems can help you integrate numerous inventory points under one umbrella for more effective, centralized administration. While the choice of available solutions is wide, the common set of must-have features for inventory management software looks like this.

Multi-location inventory tracking. Software allows for organizing and tracking inventory items by suppliers, serial numbers, tags, barcodes, SKUs (stock keeping units, or a number assigned to a product to track inventory) or other IDs at different location levels (bins, shelves, racks, aisles) across multiple warehouses. You can easily find a specific part or product, monitor locations, trace item transitions, view overstocks and stockouts.

Low inventory alerts. They appear in your dashboard when the quantity of certain items reach the preset low limit.

Automated replenishment. In case of frequent reorders, a replenishment tool can automatically create purchase orders and send them to vendors.

Digital FIFO tools. FIFO stands for first-in, first-out and describes the principle that the oldest inventory should be used or sold first. This approach leads to timely identification of the obsolete or slow-moving stock.

Barcoding. It involves both software and hardware (scanners and label printers) for assigning, scanning, and managing barcodes. Barcoding solutions bring ease, speed, and accuracy to your inventory operations such as stock-taking and verification.

Inventory optimization and performance analysis. The system automatically analyzes inventory data (such as sales history) and makes suggestions on replenishment dates and quantities. It also identifies the best performing products as well as ones with low profitability indicating where you make the most profit and which products face zero demand.

Real-time reporting. High-end solutions constantly process different metrics and generate visual reports on current inventory levels and turnovers, strengths and weak points.

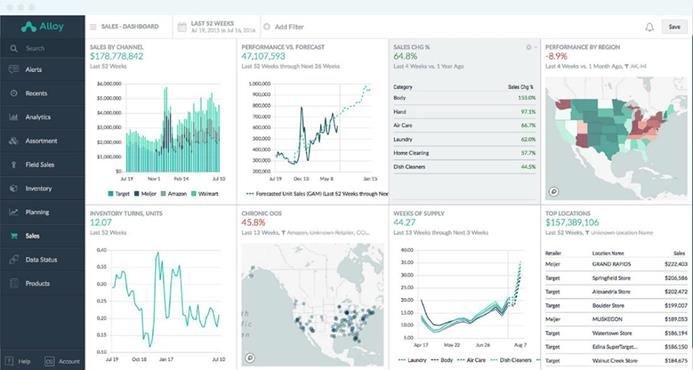

An inventory management analytical dashboard maximizes comprehension of the inventory data and trends.

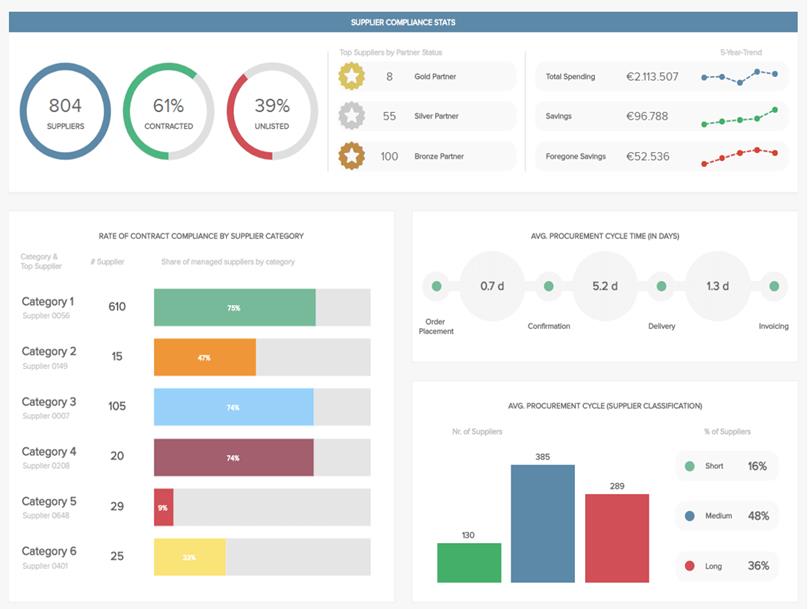

Logistics

Logistics is a huge part of SCM that bridges production and marketing, supply and demand. It covers all processes that refer to the movement of products and information between a manufacturer and a customer — namely:

The primary goal for logistics efforts is to meet customer needs in the shortest time and at the lowest cost possible. And that’s where smart technologies play a crucial role. To learn more about digital transformations in the field, read our in-depth overview of Logistics Management Systems (LMS) and their main modules.

Demand planning and forecasting

Demand planning initiates and drives operations in all segments of a supply chain, from purchasing raw materials to product distribution. In many organizations, the forecasting process still relies on tricky and rigid spreadsheets, which are hard to adapt to demand volatility. Thus, the implementation of modern demand-sensing software can give you a huge competitive advantage, bringing transparency and reliability into predictions.

Accurate, timely forecasting of customer requirements helps businesses achieve the following goals:

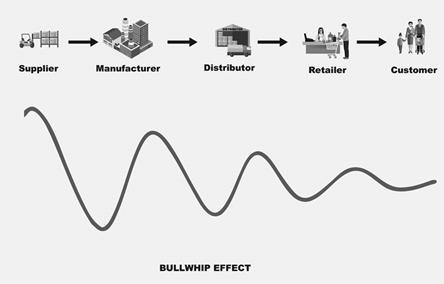

How bullwhip effect works:

We’ve already discussed how retailers apply artificial intelligence. But what digital capabilities are particularly useful for improving demand forecasting? Here are some features worth considering.

Demand sensing. A demand planning system aggregates large volumes of real-time data from multiple sources to identify demand trends and generate accurate short-term forecasts. This enables you to react quickly when unexpected changes occur.

Demand segmentation and modeling. AI-powered software can optimize forecasts for different channels, products, customers, and more. Moreover, you can simulate multiple demand scenarios and analyze consumer buying patterns to make more informed decisions.

Resource planning. Based on demand forecasting, the software makes suggestions on the volumes of resources required to meet customer needs.

Collaborative forecasting. Suppliers, partners, and stakeholders can be brought into planning to develop forecasting in collaboration.

New product forecasting. The system analyzes sales history of similar products, considers different factors (like season, launch time, or region) and applies complex models to predict demand for new goods or services.

This list can be continued and extended as new technologies are emerging all the time, penetrating deeper into the complex processes and simplifying them. In our future posts we will keep you informed about innovations in the sector. And now, it’s time to move on to integrated SCM suites encompassing all mentioned-above solutions.