Types of Light Weight Aggregate:

Light weight aggregates can be classified into the following two groups:

1. Natural light weight aggregate.

2. Artificial light weight aggregate.

These aggregate are further classified as follows:

Natural Light Weight Aggregate:

1. Pumice

2. Diatomite

3. Scoria

4. Volcanic cinders

5. Saw dust, and

6. Rice husk.

Artificial Light Weight Aggregate:

1. Artificial cinders

2. Coke breeze

3. Foamed slag

4. Bloated clay

5. Expanded shale’s and slate

6. Sintered fly ash

7. Expanded perlite

8. Thermocole beeds, and

9. Exfoliated vermiculite.

Light Weight Aggregate Concrete:

Often the light weight concrete is made by using the light weight aggregate. As already discussed, the different light weight aggregates have different densities. Hence light weight concrete made using different types of light weight aggregate will have different densities.

Concrete produced by using expanded perlite or vermiculite will have a low density of the order of 300 kg/m3, whereas by the use of expanded slag, Sintered fly ash or bloated clay etc. a concrete having density as high as 1900 kg/m3 can be obtained. The strength of light weight concrete varies from 0.3 N/mm2 to 40 N/mm2. In the production of such concrete, cement content varying from 200 kg/m3 to about 500 kg/m3 may be used. Typical ranges of densities of different light weight concrete are shown in Fig.22.1.

The strength of light weight concrete depends on the density of aggregate. Less porous aggregate, which is heavier in weight, produces stronger concrete particularly with higher cement content. The grading of aggregate, w/c ratio, and degree of compaction also affects the strength of concrete.

Structural Light Weight Concrete:

It is a concrete light in weight and sufficiently strong when used with steel reinforcement. Thus it is going to be more acceptable and economical material of construction than conventional concrete.

The 28 day compressive strength of structural light weight aggregate concrete is more than 17 MPa and air dried unit weight is not more than 1850 kg/m3. This concrete may consist either entirely of light weight aggregate or a combination of light weight and normal weight aggregate. For practical considerations, the common practice of producing structural light weight Concrete is to use normal sand as fine aggregate and light weight coarse aggregate of maximum size 19 mm. Concrete made with normal sand and light weight aggregate is known as sanded light weight concrete in contrast to “all light weight concrete.”

Workability:

Workability of light weight aggregate concrete needs special attention, as for equal workability light weight aggregate concrete gives a lower slump and a lower compacting factor than the normal weight aggregate concrete as work done by gravity is smaller in case of light weight aggregate concrete. On the other hand if a higher workability is kept, there will be a higher tendency of segregation.

In case of higher slump and over vibrations, the mortar goes down and aggregate tends to float, which is a reverse phenomenon that of normal weight aggregate concrete. In such conditions the finishing operations of deck slab and floors will be difficult. To overcome this difficulty, usually the maximum slump is restricted to 100 mm.

Due to the porous nature of light weight aggregates they have high and rapid water absorption, if the aggregate is dry at the time of mixing, it will absorb water rapidly and the workability decreases quickly. This problem can be overcome by mixing the aggregate with at least one half of the mixing water before adding cement to it However this procedure will increase the density and decrease its thermal insulation.

The light weight aggregate mixes tend to be harsh, which can be reduced by air entrainment. Air entrainment reduces water requirements and also the tendency of segregation and bleeding. The usual total amount of air content by volume is 4 to 8% for 20 mm maximum size of aggregate and 5 to 9% for 10 mm maximum size of aggregate.

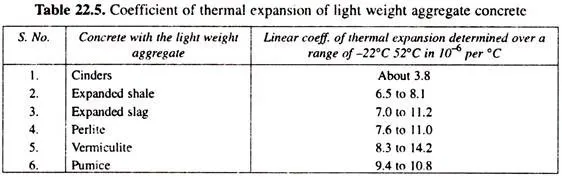

Light weight aggregate concrete exhibits higher moisture movement than the normal weight concrete. The wet concrete swells more while dry concrete shrinks more. Due to the higher drying shrinkage and lower tensile strength, the light weight aggregate concrete develops shrinkage cracks. The coefficient of thermal expansion of light weight aggregate concrete is much lower than ordinary concrete. Typical values are shown in in Table 22.5.