Classification of cracks and Cracking in Concrete

Cracking

Cracking will occur whenever the tensile strain, to which concrete is subjected, exceeds the tensile strain capacity of the concrete. The tensile strain capacity of concrete varies with age and with the rate of application of strain.

Classification of cracks

It may be classified in terms of their effects:

· Those cracks which indicate immediate structural distress

· Those cracks which may lead in the long run to a reduction of safety, through corrosion of steel

· Cracks which lead to malfunction of the structure, as evidenced by leakage, sound transfer, damage to finishes and unsatisfactory operation of windows and doors

· Cracks which are aesthetically unacceptable

Class I-Cracks leading to Structural Failure

Little difficulty arises in relation to this class. Those cracks that indicate that failure is near and that margin of safety are seriously reduced, may have formed in concrete, which was expected by the designer, to carry load in its un cracked condition .Such cracks are necessarily wide, and may lead to the detachment of parts of the structure.

Class II Cracks causing Corrosion

There is no unique relationship between crack width and the onset of corrosion. Part of the difficulty arises from the nature of cracks themselves. For flexural members, many cracks taper from a certain width at the surface of the concrete, the near zero width at the steel-concrete interface. However, flexural cracks that are controlled by the overall depth of the beam are not of the tapered shape, and it is likely that cracks due to temperature and shrinkage are nearer to being parallel sided. It has been assumed for many years that, since wider cracks would give easier access to aggressive substances, corrosion could be controlled by controlling crack widths and that permissible widths should be a function of how aggressive the environment was many complicated formulas for the calculation of crack widths in flexural members have been devised with the object of controlling corrosion. But extensive tests on beams in which the cracks are normal to the axis of the bars show evidence of any relationship between corrosion damage and crack width.

When cracks run along a bar, much more of the bar is in an exposed position, and it might be expected that there would be a closer relationship between crack width and corrosion in this situation. There is a little evidence however, that cracks whether transverse to the bars or running along the bars, pose any create risk of increased corrosion, if they are less than 0.3mm in width.

Some cracks, which are parallel to a bar, may have been caused by the corrosion of that bar. These cracks will widen as corrosion proceeds, and will eventually lead to spalling and exposure of the corroded bar. A crack of any width, which is judged to be brought about by corrosion, is an indication of a deteriorating structure, and therefore no minimum width, below which the crack is not significant, can be set. A crack that indicates the corrosion of the bar is actually showing that the corrosion will continue, unless positive measures are taken. Merely filling the crack will not achieve the result.

Class III-cracks affecting Function

The cracks in this class, which have the most serious consequences are those that allow liquid-retailing structures to leak, or that occur in roofs or other structures, intended to be waterproof. BS 8007 prescribes limiting crack widths and details methods of predicting the widths. The maximum design surface crack width, for direct tension and flexure or restrained temperature and moisture effects are:

Severe or very severe exposure-0.2mm

There are only limited test data available on what constitutes the limiting crack, for preventing leakage. Flow through a parallel-sided smooth crack, can be calculated in terms of head, crack width, crack length and fluid viscosity. The difficulty with concrete is that the cracks are not smooth or parallel-sided.

Class IV-cracks affecting appearance

For class 4cracks,it has been suggested that crack widths up to 0.3mm in width are acceptable aesthetically, but there are no good guidelines. Various attempts have been made to establish what constitutes an acceptable crack on an aesthetic basis, but in the end, there is no rational basis for aesthetic decisions. The aesthetic objection to cracks may be summarized as:

� Cracks cause alarm about the safety of the structure

� Cracks lower the visual acceptance of the structure (a) by modifying surface textures and damaging the visual effect intended by the designer and (b) by giving an appearance of cheapness or bad building.

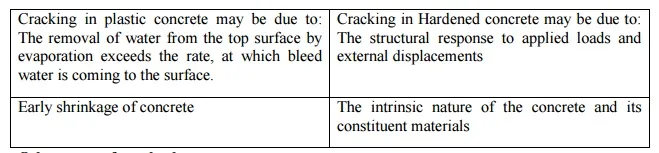

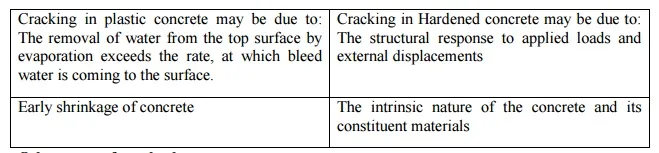

Causes of cracking:

Other types of cracks due to:

· Delayed curing

· Formwork movement

· Excess vibration

· Sub grade settlement

· Finishing

· Early frost damage

· Unsound materials

· Long-term drying shrinkage