Effect of Speeding Trains and Pressure Changes in the Chunnel

Pressure valves in the Chunnel

involve an important design concept. The designers of the Chunnel have

optimized the air dynamics inside the tunnel so that passengers inside a train

feel almost no effect due to pressure changes. How did they achieve this feat?

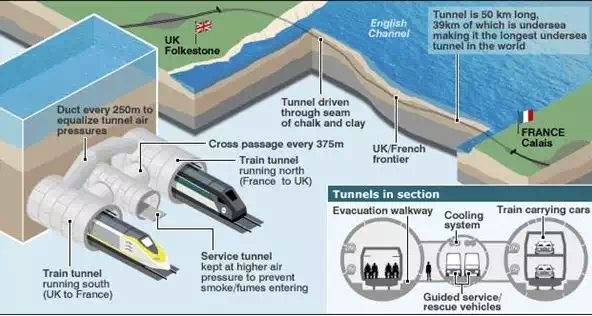

What is the Channel Tunnel?

The Channel Tunnel, which is

popularly known as the Chunnel, is an undersea rail tunnel that runs between

the United Kingdom and France mostly under the English Channel. This is the

second largest undersea channel in the world and has the largest under sea

portion of any tunnel. The Chunnel is used for high speed passenger trains,

international rail freight trains, and vehicle transport by Eurotunnel Shuttle.

In the Chunnel, a from

"Paris to London journey" takes only two hours and fifteen minutes,

thanks to the extreme efforts of the designers and workers. Due to its

complexity in designing and greater risks in construction, the Chunnel is

considered one of the engineering marvels in the modern world. Also it was

named one of the Seven

Wonders of the Modern World by

the American Society of Civil Engineers in 1996.

During the design process

engineers had to face severe challenges because of the extreme nature of the

project... when they began the constructions in 1988. Several interesting

design concepts were involved with the Chunnel, which opened in 1994. One such

concept was thepressure

relief valve system of the Channel

Tunnel.

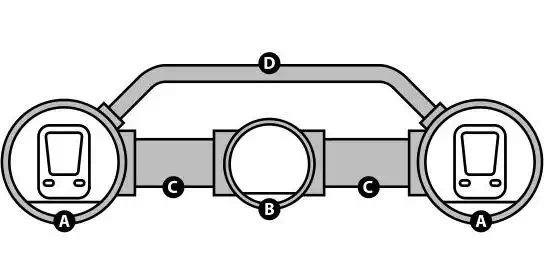

The Design of the Channel Tunnel

The Channel Tunnel links Folkestone, Kent in the United Kingdom with Coquelles, Pas-de-Calais in northern France by a 50.5kilometer

long undersea rail tunnel. It consists of two 7.6 m internal diameter rail

tunnels and a 4.8 internal diameter service tunnel. All three tunnels are 50.5

km in length and the service tunnel lies between rail tunnels that are spaced

30 m apart. There are pairs of cross passages that connect rail roads to the

service tunnel. They are located along the whole route spacing at 375 m. Each

of these cross passages has an internal diameter of 3.3 m. Also there are

piston relief ducts of 2 m internal diameter for connecting rails tunnels at

250 m spacing. Knowing how these pressure valves in the Chunnel work is quite

important when we analyze this remarkable

civil engineering feat. The average depth of the Chunnel under the seabed is 45

meters. 37.9 km of the total length is under sea. The total cost for the

Channel Tunnel project was $21 billion. That's 700 times more expensive than

the cost of the Golden Gate Bridge in the US.

The service tunnel is used to

provide fresh air ventilation, entrance to cross-passages and equipment rooms,

and for emergency evacuation. The Service Tunnel Transport System (STTS) allows quick access to all areas of the

tunnel. Rail tunnels are used by passenger trains travelling at a very high

speed. When a train moves in a tunnel, they dominate the air flow in the tunnel

creating massive variations of air pressure. This may create problems for the

passengers in the train. This is one of the main considerations in the design

of the Channel Tunnel.

Air Dynamics in a Tunnel

When a train passes through a

channel, usually it occupies almost all the cross section of the channel by

seriously limiting the movement of air. In the open air, when a train (or any

other vehicle) travels along the road, air is always being pushed away by the

vehicle. In this case, air can move anywhere except into the ground. But in a

tunnel, air can't move anywhere except along the tunnel and air has to be

pushed away along the tunnel. Therefore when the train moves, the air pressure

behind the train is very low as the air is pushed away by the train. To

compensate for that low air pressure, suction is created by pulling air into

the tunnel. Actually this process is called piston effect as this is similar to the piston inside

an engine. Due to low pressure at the back of the train there is a movement of

air from front to back over the length of the train. This pressure gradient

further increases the aerodynamic drag of the train.

Let's find out how the

pressure valves and ducts increase passenger comfort and train efficiency.

Pressure valves in the Chunnel

work to reduce the air pressure and drag on the trains that drive inside the

tunnel. The Channel Tunnel designers have optimized the spacing of these

pressure relief valves (piston relief ducts) by using air dynamic calculations

and computer simulations. How pressure valves in the Chunnel work? How actually

these pressure control valves have been able reduce air pressure? These are

questions raised by many interested parties. The Chunnel Channel is the second

longest undersea channel in the world and has the longest undersea portion. Its

pressure valve system is another incredible design. It would be quite

interesting to know how this pressure relief valves work.

The air resistance (drag) is

proportional to the squared value of the speed of the train. At very high

speeds, drag forces become very high so that the train needs extra power

(engine power) to move forward. In a shorter tunnel, the slowing of the train can

be neglected due to this air dynamic drag. But, being a tunnel with 50km in

length, the drag force is very high in the Chunnel. It was calculated that the

pressure over the length of a single passenger vehicle shuttle travelling at

160 km/h would be build up to 20 kPa. In this

situation air dynamic drag is 35 MW. (Engineering the Chunnel Tunnel by Colin

J. Kirkland – p. 216). Such a situation would be uncomfortable for passengers

and necessary design considerations had to be implemented to prevent or reduce

that.

How Pressure Valves in the Chunnel Work

To reduce the pressure

variations in the tunnel during the movement of a train and assist the

passenger comfort, pressure relief valves were installed in to the tunnel. They

are known as piston relief ducts.

When a train moves, air pressure of the front end is increased. This high

pressure air flows to the low pressure area of the other rail tunnel through

the piston relief ducts. The back end of the train has a low pressure region.

Air flows into the piston relief ducts to reduce the pressure of the back.

Therefore due to the act of these pressure valves in the Chunnel, the pressure

difference of the above mentioned shuttle is reduced to 6 kPa. Also it reduces the relative velocity of

the air, resulting in a lower drag.

The number and the size of

these piston relief ducts have been optimized after a number of aerodynamic

studies and calculations. Considering reduction of the drag, cost, and

passenger comfort, the ducts have been arranged with 2 m diameter at 250 m

spacing. There is a disadvantage of this pressure reducing valve system. That’s

the lateral forces excreted on the trains due to strong flow of air through

piston relief ducts. The shuttle wagons with square cross sections restrict the

air flow which causes the effect. The Eurotunnel has taken precaution by adding flow restrictions to

the piston relief ducts.

But the restriction can be

removed if the use of shuttle wagons can be avoided.

When a train passes through

the tunnel, the air velocity reaches 20m/s- or half of the train's speed. If

the piston relief ducts are open, it is very difficult for maintenance

personnel to conduct work under such a higher air speed. To prevent this

problem, dampers were installed on each piston relief duct. Then they could be

closed during maintenance and thus provide no difficulty for those personnel.

Another important point is that this removes the pressure relief effect of the

ducts, which is required so that the trains can run at slower speeds with

reduced pressure, drag, and velocity effects.

By any means, the Channel

Tunnel is a remarkable engineering feat for which the creators- the designers,

engineers, builders, and technicians- can all be proud. The pressure valves,

dampers, and relief ducts in the Chunnel are an important part of the tunnel

design. They reduce aerodynamic drag on the trains and improve efficiency and

passenger comfort.