Ozone Resistant Materials

The ozone layer protects

humanity from the effects of ultraviolet rays, but ozone itself because of its

high capacity to react through its extra oxygen atom causes the need for ozone

resisting material to be used for ensuring the longevity of buildings.

Ozone and Its Effect on Materials

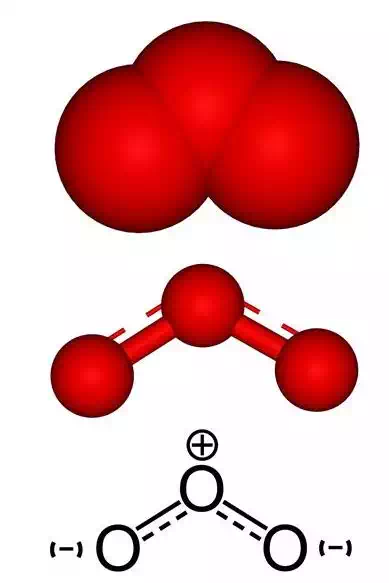

Ozone is an oxidizing agent

that is very powerful; its power comes from the free oxygen atom that results

after atmospheric oxygen is converted into O3 . This

is the result of electrical discharge from lightning and other atmospheric

actions that produce electrical activity. This third atom of oxygen in ozone is

not very stable and usually last very long, but it is constantly looking to

link up with other atoms to achieve some stability. This is what causes the ill

effects of ozone. It degrades material that it comes into contact with it and

causes some sort of fading, as well as a loss in tensile strength, which

accelerates aging and thus a reduction in the value.

Ozone causes substantial

damage to rubber products, surface coatings, and polymers, all of which are

used extensively in the building industry. While inorganic materials remain

largely unaffected by ozone, its combination with sulfur dioxide

and nitrogen dioxide present in the atmosphere has a deleterious effect on

metals. For the same reason, the zinc that is contained in most paints causes

it to be vulnerable to ozone. Of all the metals, copper and tin seem to be most

vulnerable.

Building Materials That Need Ozone Protection

Ozone is formed as a result of

electrical discharge combining with the atmospheric oxygen, and this is a

situation that can be also largely prevalent in electrical equipment and

installations. The ozone that does get formed can affect the insulation of

wires and cause them to deteriorate, especially when the concentration of ozone

exceeds 20 percent. For this reason, standards have been developed for

insulation that will be resistant to such effects. This also includes the

insulating compounds that are used to join wires and cables.

Rubber seals and sealing

compounds used to weatherproof glazed windows are other building materials that

are affected by ozone. Ozone in combination with ultraviolet rays cause such

seals and compounds to become brittle and thus less effective in their

function. Natural rubber and PVC are very vulnerable to ozone, and their use

these days has become very limited in the building industry. Ozone gas attacks

the polymers of which these materials consist, causing cracks in them to grow

longer and deeper and, thus, complete degradation of the material. The

application of waxes to protect the surface of these materials has been known

to be effective, but these waxes are affected by heat and mechanical effects.

This has led to the development of EPDM, which has a high resistance to heat,

ozone, and UV rays, plus a resistance to color fading.

This has led to architects specifying their use for weatherproofing of windows

and around glass in glass facades.