Multi-Stage Flash Distillation for Desalination

This is an article on

multi-stage flash distillation where we will look at what is multi-stage flash

distillation. Distillation has evolved from the old steam coil vacuum

evaporators, to today’s modern reverse osmosis and multi-flash distillation

plants that are used for desalination of seawater.

Introduction to Multi-Stage Flash Distillation for Desalination

Many years ago when I was a

young boy at sea, ships and in particular steam ships, had evaporators used to

produce fresh water from seawater. When I was promoted to 4th Engineer Officer

I was told I would be in charge of the evaporators (or "vaps" as we called them). Little did I know that I

would spend hours coaxing a little bit more water out of these old beasts!

Anyway in those far-off days

we made the water for the boiler using this method of coil evaporators, more

about this later.

This is an article in Civil

Engineering on multistage flash distillation for desalination of seawater. We

begin with an overview of evaporation and distillation methods.

Overview of the use of Evaporators and Distillation Methods for

Desalination of Seawater

Evaporators became popular

with the advent of ships' steam engines, which required better quality,

pressure, and quantity of steam from the ships' boilers. Evaporators were the first method used to

produce distilled water from seawater to feed the ships boilers. Meanwhile on

land, countries that were experiencing constant drought conditions were

starting to use large-scale thermal desalination plants to produce fresh water

from seawater or underground brine aquifers.

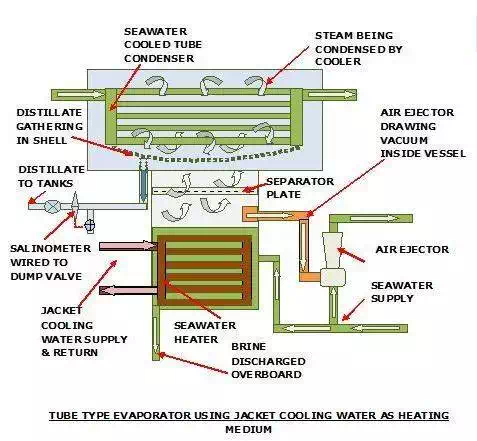

A sketch of an evaporator that

was used forty years ago on steamships is shown below, and it was one of the

types used in land desalination plants. This is drawn from memory, but gives a

general idea of the process.

Reverse Osmosis (RO) was used

as desalination method from the mid-1960s, and it was the most popular method

of distillation. However since the advent of multi-stage flash distillation,

this type of plant produces the most freshwater from seawater, worldwide.

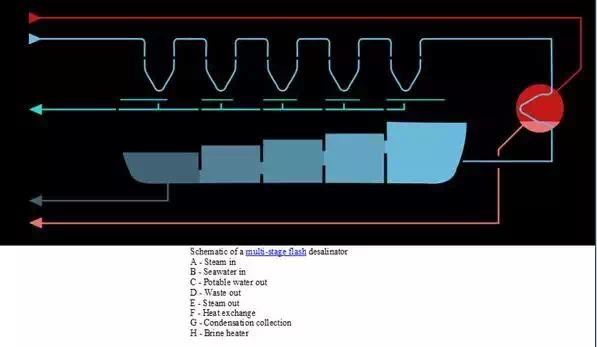

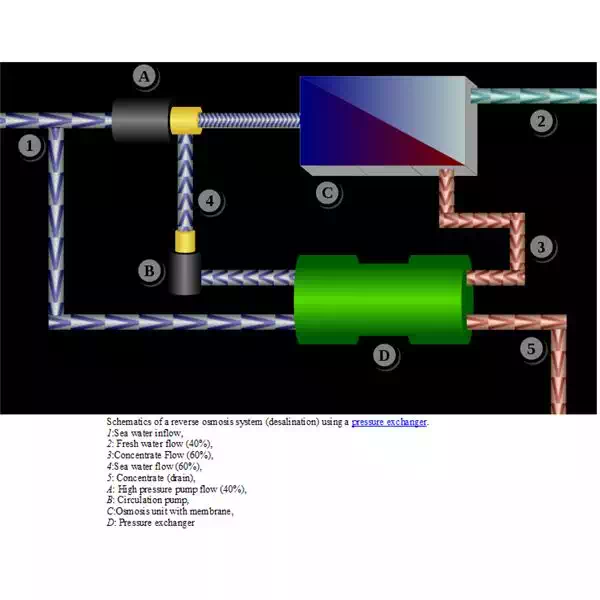

Schematics of a reverse

osmosis system and multi stage flash (desalination) are shown below:

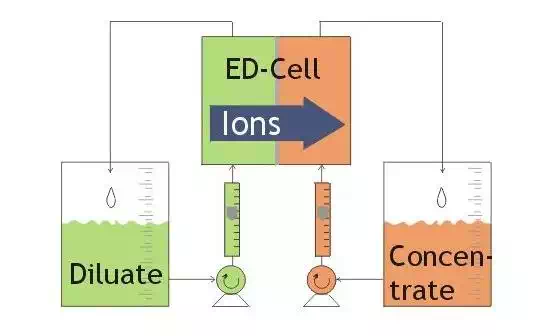

Before leaving this section it

is worth a quick look at electrodialysis. This

method uses electricity to remove the salts from water through ion exchange

membranes at a very competitive rate. Although it is used mainly for brackish

water or low salt content water, it has been used for desalination of seawater.

A typical ED

Cell is shown below:

Multi-Stage Flash Distillation for Desalination

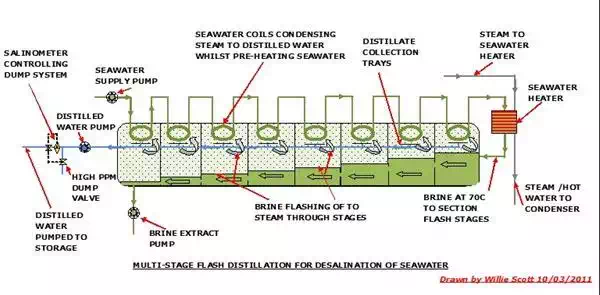

Multistage stage flash

distillation for desalination is carried out in a pressure vessel that is

divided into numerous sections that have decreasing pressures and temperatures.

The sections each have a set of coils that have seawater pumped through them. These

coils serve two purposes: condensing the steam produced by the flash

evaporation and preheating the seawater to almost the required temperature for

distillation.

The seawater then passes

through an inline steam heater, taking it up to a temperature between 70ᴼC

and 100ᴼC; the seawater now being considered to be brine. Multi-flash

distillation plant engineers will sometimes reduce this temperature to decrease

the formation of scale.

The brine now passes into the

different stages and, as it is at a higher temperature than the sections, some

of it flashes to steam. This is condensed by the seawater coils at the top of

the sections, with the condensate dropping down onto the collection trays under

the coils.

This continues to the final

stage when the brine is pumped to waste and the collected distilled water is

delivered to storage tanks. There is a salinometer on

the discharge line to the storage tanks that operates a tank isolating

valve/dump valve in the event of a high ppm alarm.

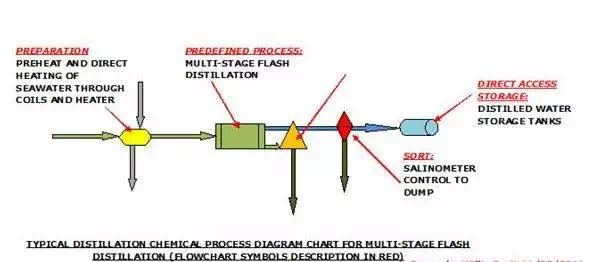

A typical multi-stage flash

distillation plant is shown below, along with one type of distillation chemical

process diagram chart applied to desalination.