Intumescent Paint and Coatings

Spray-on fireproof coatings

are an effective method for protecting equipment and structures from fire and

heat. However, these materials tend to have particular advantages and

disadvantages. Read this article to learn about the properties, indications and

applications for these coatings.

An intumescent paint is a type

of coating that is a fire retardant that also protects structural members from

the ill effects of hot weather and sun exposure. It can be applied to wood,

bricks, walls, and other structural members of a structure, to steel and

plastic piping, and to fiberglass structures. These coatings are usually made

of organic substances like epoxy resins and other thermosetting polymers that

have high resistance to heat and fire.

How Intumescent Spray-On Fireproofing Works

Intumescent substances swell

when exposed to heat and fire. When used as a paint coat or fireproofing spray,

they form a protective layer on the surface. When exposed to fire or excessive

heat, the protective layer will resist and absorb heat, thus protecting the

structural member from damaged or deformation. Volume expansion and density

reduction takes place when temperature starts to rise. Organic materials used

for the manufacturing of intumescent paints are inert at low temperatures, but

they swell instantaneously when brought into contact with heat or fire.

Intumescent paints are either

solvent based or water based. In both cases, they contain a sufficient amount

of hydrates to help in cooling off the temperature because of evaporation

effects. Water based paints are used most often because they are inexpensive

and widely available. Solvent based intumescent paints have, so far, seen only

limited usage.

Another classification system,

which takes into account the nature of the char produced by intumescent paint,

is also in effect.

Soft char intumescent paints produce

only a light char upon initial heat exposure. The char is a bad conductor of

heat, and it does not allow the heat to pass through the paint coat and reach

the structural member. It also contains hydrates which have a cooling effect.

This is used primarily for the protection of structural steel.

Hard char intumescent paints

produce hard char, which is also a very poor conductor of heat. These paints

are exclusively used for plastic pipe protection. The major constituents of

hard char are graphite and sodium silicate.

Advantages and Applications

Intumescent coatings prolong

the structural life of steel. As protected steel is less exposed to frequent

temperature variations, its load bearing capacity also increases.

The coatings can be applied

off-site as well as on-location. Off-site fireproofing means there is enough

time for workers to fit, erect, and adjust their structural components. Faster

and easier construction, reduced on-site activities, and ease of assembly are

the major advantages of off-site coating.

These specialized paints have

a wide range of use. They can be used for steel coatings, wooden coats, or for

structural components like concrete as well. Recently intumescent fireproofing

sprays have been developed that can be applied to fiber glass

structural components, too.

Advantageous use of these

products can be made in refurbishment projects. The structural, aesthetic, and

architectural value of the structural objects remains preserved.

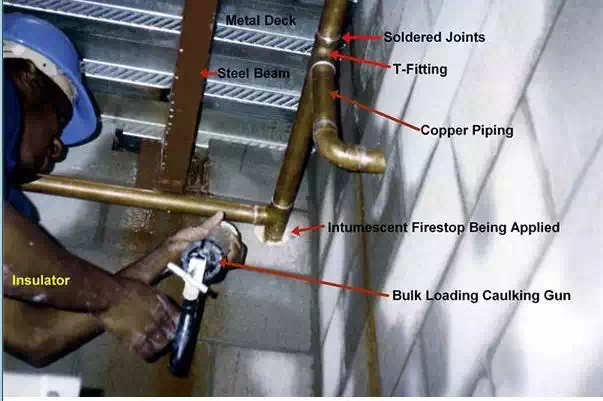

As already stated, intumescent

paints have a huge scope of use. These paints are mainly used in fire-stopping,

closures, and fireproofing works in buildings, houses, and manufacturing

industries. Gasketing applications also

make use of intumescent spray-on fireproofing paints. Major use of these paints

is found in offshore drilling, aircraft maintenance, and the ship building

industries.

Disadvantages

The intumescent fireproofing

industry is on the rise and has already created a stir in the market. However,

there are certain drawbacks associated with these paints.

UV exposure, operational heat,

and the humidity of the work area are three major factors that affect the

performance of intumescents. Intumescents are particularly vulnerable to

environmental exposure at the time of application.

For sodium silicate based

intumescent fire sprays, having rubber or epoxy in the coatings becomes

mandatory in order to promote adherence.

They have a limited fire

resistance period. The best quality, i.e. most expensive, intumescent fire

sprays will not preserve your structural member for more than sixty minutes or

so. As the fire resistance time duration increases, the costs also increases,

and the cost rise is usually exponential.

Alternatives to

the Intumescent spray-on paints are also available in the market.

Flexible blanket

systems - Good - cheap,

easy to use, dry fixing methods; bad - poor appearance.

Other

fireproofing sprays - Good

- covers complex details, low cost, durable; bad - on site application means

more on-site headaches.

Board systems

- Good - clean

appearance, dry fixing, can be used on unpainted steelwork; bad - does not

cover complex areas.