Wöhler Fatique Curves (S-N) for Shearing Stress

August Wöhler, a German engineer, studied the fatigue

characteristics of materials under cyclic loading. His studies resulted in

development of S-N fatigue curves for shear stress. The applications of S-N

curves, how to use them, and other major aspects related to Wöhler curves are focused on below.

S-N curves are two-dimensional

curves, plotting cycles of failure (N) and shear stress (S) on X-Y axis on a

logarithmic scale. The prerequisite of plotting these curves is that the stress

has to be cyclic in nature. Every material, when subjected to alternate or

cyclic loads, will fail if the loading surpasses its resistance. However, if

rupture occurs at a load less than the projected resistance of the material,

then it will be termed as fatigue. Major factors affecting the

resisting force of a material, known as the "endurance limit,"

include:

Corrosive

environment

Temperature variations.

Surface finish and exposed

area.

Notches.

The main reason behind fatigue

rupture is the development of minor cracks due to successive loading. With

every loading, these cracks grow bigger, resulting in untimely failure. Wöhler curves help in the determination of upper limit

of shearing stress that can be exerted on a material.

Plotting the Wöhler Curves

Plotting S-N curve includes

plotting initial strain against life to failure. In the laboratory, a

sinusoidal stress is applied and the process is known as the Coupon

Testing process. These curves are also known as a Stress-Life diagram.

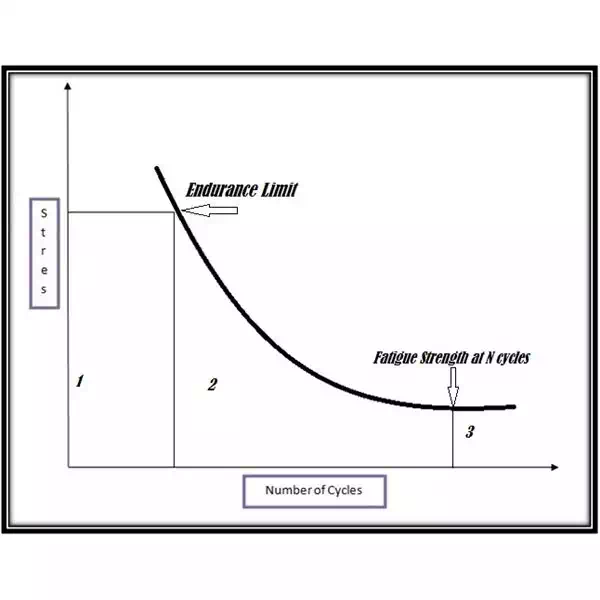

For example, let us consider fatigue behavior of

compression members like springs. The following figure has been divided into

three different regions.Region 1 denotes

the area of ogilocyclic fatigue. In this

region, rupture occurs at very small alternations and the material is often

subjected to plastic deformations.

Region 2 denotes the area of limited

endurance.

Region 3 is known as the security zone under

low constraint.

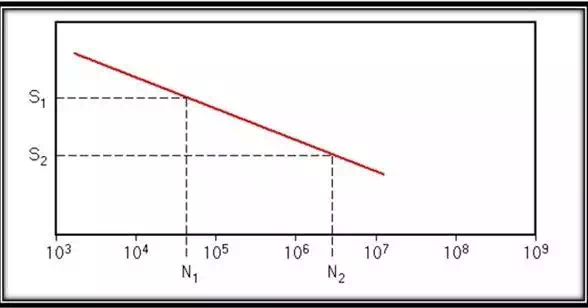

Now let us consider an ideal

S-N curve, which would be a straight line. By approximating a stress curve, we

can calculate the value of stress amplitude. The curve is used to determine

the Basquin Slope.N1 = N2 (S1 / S2)1/b is

the general relationship between two failure cycles at different time intervals.

and the Basquin Slope

is determined by the equation:

b = -[(logS1

– logS2)/ (log N2 - logN1)], where

S1, S2 are stress values for

corresponding number of failure cycles denoted by N1 and N2. b denotes slope of the S-N curve.

Once slope of the curve is

determined, it becomes very easy to find out the value of stress amplitude for

any two S-N values on the curve.

Wöhler Curves can also be used to

determine the values of fatigue ratio for different materials. Fatigue

Limit can be defined as ratio of ultimate strength (Su) and endurance

limit (Se) of a material. The value of fatigue limit usually varies between

0.25 and 0.60.

For instance, steel's fatigue

ratio is expressed as Se = 0.55 Su.

Notches mean discontinuity on

the surface of structural members and notches play an important role in

deciding the stress values for materials under testing. These discontinuities

are also known as stress concentration factors. Stress

concentration factor of a structural member is calculated as Kt= (Smax/S), where Smax is maximum local stress and S is nominal stress

of the member.With the help of Kt, we can determine the fatigue notch factor using the S-N

fatigue curves for shear stress. The fatigue notch factor relates the

un-notched fatigue strength, which is the

endurance limit for ferrous members like steel, of a member to its notched

fatigue strength:

Kf = Se(un-notched)

/ Se(notched), Se(un-notched) is achieved only under ideal conditions.

Applications of Wöhler Curves

Wöhler Curves have a wide scope of use.

They are used mainly in the construction sector. Other than that, they are used

in the aerospace industry, heavy lifting cranes, bridging and shipping, railway

industry, offshore drilling and petrochemical industry. S-N curves are very

helpful for design engineers because predicting safe loads that a structure or

building can bear is very important for safe designing. Different codes and

regulations mark it as a top priority to make sure structural components are

able to bear cyclic loads. There is a Modified Wöhler Curve

Method, which is used to determine joint strengths. Welded joints riveted

joints, made of steel and aluminum can be

brought under the test and with the help of Wöhler Curve,

safe design shear stress can be predicted. While designing, Wöhler Curve values are not used as such and 10-15%

margin of safety is taken into account.