Reinforced Concrete - Beam Design

The applied loads include direct compression

forces, as well as, compressive and tensile stresses that are caused by sagging bending moments to the beam. The

induced compressive stresses are located in the material fibres above the

neutral axis of the member and the induced tensile stresses are located below

the neutral axis.

1. Determine fy and fcu according to required material properties

2. Determine preliminary dimensions of the

beam, b and h

3. Find effective depth, d

d = h - cover - bar diameter

Concrete covers are to be

designed for requirements of fire resistance and durability.

4. Find span/depth ratio, L/d and make sure

that L/d is less than 20

Deflection should be

checked using the span/depth ratio.

Cracking should be

designed for SLS and should meet the requirements of minimum

reinforcement needed and spacing.

Detail Design

1. Find w

w = 1.4DL + 1.6LL

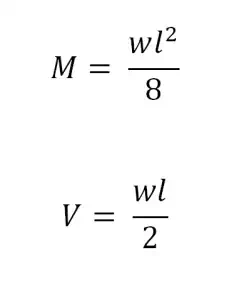

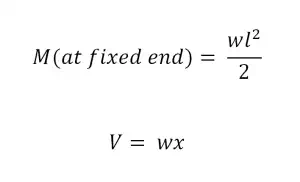

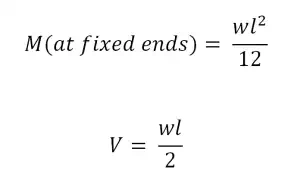

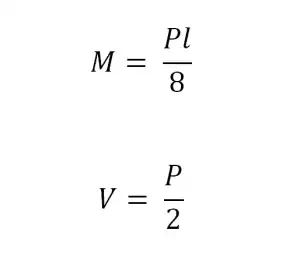

2. Find the design moment and shear, M and V

Simply supported with Uniformly Distributed

Load

Simply supported with Concentrated Load

Cantilever Beam with Uniformly Distributed Load

Fixed ends with Uniformly Distributed Load

Fixed Ends with Concentrated Load at the Center

t

The effective span of beams, l, should be

assumed to be the effective span of the member in its simply supported

condition for conservative purposes. This span equals the exact distance

between supports.

2. Establish concrete grade, fcu, in N/mm^2

3. Find the depth to neutral axis, x, in mm

Depth to neutral axis, x, from compression

face is limited to:

x ≤

0.5d for fcu ≤ 45 N/mm^2

x ≤

0.4d for

45 < fcu ≤ 70 N/mm^2

x ≤

0.33d for

70 < fcu ≤ 100 N/mm^2

3. Design rectangular beams for flexure

The design ultimate moment M should be designed greater than the ultimate bending

moment.

*Also applicable to flanged beams when the

neutral axis of the beam lies within the flange

K'

=

0.156 for fcu ≤ 45 N/mm^2

K'

=

0.120 for

45 < fcu ≤ 70 N/mm^2

K'

=

0.094 for

70 < fcu ≤ 100 N/mm^2

If

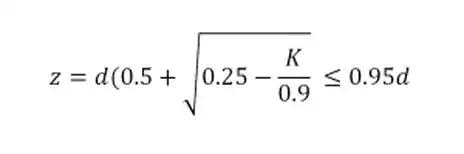

K ≤ K', compression reinforcement not required

x

=

(d-z)/0.45 for fcu ≤ 45 N/mm^2

x

= (d-z)/0.40 for

45 < fcu ≤ 70 N/mm^2

x

=

(d-z)/0.36 for

70 < fcu ≤ 100 N/mm^2

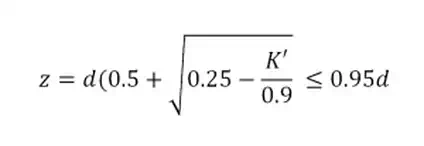

If K > K', compression reinforcement

required

x

=

(d-z)/0.45 for fcu ≤ 45 N/mm^2

x

=

(d-z)/0.40 for

45 < fcu ≤ 70 N/mm^2

x

=

(d-z)/0.36 for

70 < fcu ≤ 100 N/mm^2

The maximum amount of reinforcement in

concrete members (beams, columns, or slabs) should not exceed 4%.

5. Design rectangular beams for shear

Shear stress in beams

Usually, the shear force and the shear

stress should be obtained from the face of

the support.

Shear reinforcement

Shear reinforcement should

be designed for ULS and should be provided in the form of vertical

links or bent-up bars. Shear forces are transferred to

the vertical links that act with diagonal concrete struts in compression.

Therefore, in beams, the links will act in tension and the concrete in

compression.

Shear reinforcement are required to resist the

following failure mode caused by shear:

● Inclined tensile cracks on beam

● Inclined tensile stress failure caused by shear

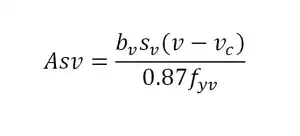

a. If v < 0.5vc, minimum links should be

provided.

b. If 0.5vc < v < vc + vr, links should be

provided, in which the area of shear reinforcement provided is

and where fcu not reater than 80.

c.

If vc +vr <

v < 0.8√fcu or v = 7 N/mm˛, links or links with bent-up bars should be

provided. Links should not be more than 50% of shear resistance.

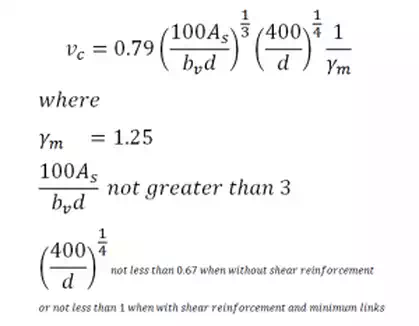

Concrete shear stress, vc

5. Determine whether maximum deflection is

below deflection capacity

Allowable Limit = L/250