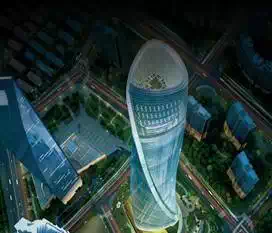

Genslerís

Shanghai Tower

The Shanghai Tower is the tallest building in

China and second tallest in the world. In order to achieve its height, the

geometry of the tower had to be optimized to

resist lateral loads.

The cross sectional geometry is a spiral

equilateral triangle with each floor rotated slightly from below, creating

a 120 degree angle between the topmost floor and the lowest level.

The spiral geometry actually increases lateral resistance by 24%, as opposed to tapered box geometry. This saved $58 million in materials and construction procedures. There are over 7000 different geometries and 20000 dual-skinned curtain wall panels that make up the structural geometry.

Due to its complexity, it is quite difficult

to utilize AutoCAD and other traditional 2D modeling methods

to present and to analyze the spiral geometry. However, with Autodesk

Revit Structure, the design team can design the

geometry in 3D. Structural engineers can use this BIM model to analyze how

the wind and seismic loads affect the spiral geometry.

They were able to optimize both building materials and the structural framing system, by producing and

choosing from more than 20 options of structural geometries.

Eventually, the design team chose the

structural spiral geometry frame with super columns, outrigger trusses, and an

inner concrete core due to its combined strong lateral resistance.

Revit and Naviswork were used for BIM clash detection. During the design of

the towerís basement, the team found seven design clashes using those BIM software. During construction, there were no

more clashes and they focused their BIM efforts in combining Revit models and fabrication models in Navisworks for coordination.

Source: http://du.gensler.com/