Transfer

structures

Transfer structures are often times used in

tall buildings, usually for transferring high forces and loads to other

structures that can resist them. For example, a transfer beam can transfer

loads from stories above to stories below. Usually, transfer structures can

optimize space by changing column grids between stories so that structural

framing design can be flexible. We will explore the different types of transfer

structures.

Transfer Plates

The construction of the transfer plates is usually considered difficult. First, the transfer

floor of a structure is usually located at higher stories. Therefore, the plate

is to be erected high up at higher level stories.

Moreover, transfer plates are heavy (thickness is around 3m and the area can be

up to 1500 m^2). This provides limited construction space and formwork options.

There are several solutions:

Falsework systems, such as steel girder

trusses, can act as falsework erection system AND working platform for

reinforcement fixing and concreting.

1. Propping that span below 3-4

floors can be erected to support the

transfer plate.

2. Post-tensioning method can be used to reduce the thickness of the plate

structure and reinforcement content.

Transfer plate design is based on the slab thickness and should consider

flexure and concrete crack control.

|

|

|

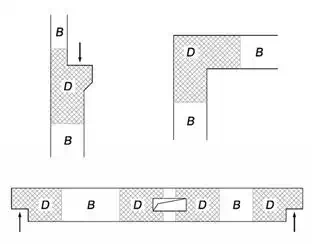

B vs D Regions

Transfer Beams

Transfer beams transfer heavy and

concentrated loads through shear. In order to avoid progressive collapse, the

transfer beam should be cast monolithically

and continuously while spanning over several supports. The structural system

should also provide an alternative load path for load path redundancy.

Moreover, for transfer beams, deflection controls. If the transfer beam

deflects, all the floors above the transfer beam will deflect with it.

Transfer beam design is different from that of

a main or secondary reinforced concrete beam design. This is because transfer

beams have nonlinear stress distribution caused by large concentrated point

loads from the column loads of the stories above. This will induce a

discontinuity region due to the concentrated loads. Linear elastic theory for

standard beam design cannot be used.

For transfer beam design, you can either use the deep beam method or the strut and tie

model method, depending on design assumptions. We will focus on the strut and

tie model. The strut and tie model designs for nonlinear stress distribution

and behavior of complex members using

simplified truss models.

Here is the strut and tie design process:

1. Define the framing, loads, and reactions

of the structure

2. Define the B & D regions

3. Strut and tie model is based on both the

St Venantís Principle and the Bernoulli

Hypothesis. B regions are based on the

Bernoulli Hypothesis, where linear strains are. The beamís flexural check can

use this regionís linear elastic theory method. D regions are based on St VenantísPrinciple.

This region occurs due to discontinuity caused by concentrated loads, which

leads to nonlinear stress distribution. This portion of the beam is idealized as a truss, where the members are axially

loaded. FEM analysis or empirical approximations are to be

used.

1. Determine the inclined angle between the

strut and the tie members. This inclined angle is different and can be

determined under your respective codes. Usually, the angle should be more than

25 degrees.

2. Design B regions

3. Make a STM to define stress flow

in D region

4. Find member forces of the truss and

design the members

Source: https://www.djc.com/

Steel Transfer Trusses

Like the strut and tie truss model, the

steel transfer truss consists of axially loaded members which only transfer

axial forces through pinned joints. The trusses are lighter in self-weight and

can transfer loads over large spans. Parallel chord trusses, such as lattice

girders or floor girders, are usually used for

the transfer structure.