Steel: Beam Design

Steel beams are to be

designed to suit the following limit states:

● Bending strength at ULS (including local

buckling of flange or web, lateral torsional buckling, and plastic moment

capacity)

● Lateral torsional buckling is checked when extreme fibres at the top part of the

neutral axis of the steel beam is undergoing compressive stresses due to

downward loads onto the beam. The applied loads creates compression in the top

flange of the beam, where it buckles, and tension in the bottom flange of the

beam. Torsional stresses will then be created due

to the web resisting the flange from buckling along its length, but during this

process, inducing twisting deflections.

● Shear strength at ULS

● The beam should

be designed to resist shear forces parallel to the web of the beam.

● Web shear buckling

● Web shear buckling needs to be checked

when the beam has a slender web. In this case, the shear capacity will then be governed by web shear buckling.

Stiffeners can be erected on the web to

resist web shear buckling. Moreover, if transverse forces are present and

distributed from flanges into webs, web buckling would need to be further checked.

● Deflection at SLS

Sizing

The following are the typical minimum column

section sizes for braced frames:

● 203 UC = up to 2-3 storeys high

● 254 UC = up to 5 storeys high

● 305 UC = up to 8 storeys high or long

spans

● 354 UC = 8-12 storeys high

Scheme Design

1. Determine the live load on the beam

2. Find the allowable deflection based

on unfactored imposed loads and check

against maximum design deflections For beams,

deflection is usually the most critical case for long spans and shear is

usually the most critical case for beams with short spans and large loadings.

Allowable Deflection Limit = Live Load / 360

3. Find total ULS loads on the beam

Total load = Span x Load width x Critical Load

x ULS factors

Steel structural members are designed to

resist yielding, buckling, and rupture under ultimate forces. Beams are designed to resist ULS bending and shear forces.

4. Determine support conditions of the beam

and determine effective lengths, L, based on the support conditions

5. Determine M, the maximum bending moment,

and V, the maximum shear force

M = w x L

6. Determine the Second Moment of Inertia for

the beam (where I has units of cm^4)

I = 0.5 x Ratio x K x L x M

where

M = maximum bending moment (kNm)

L = effective length of beam (m)

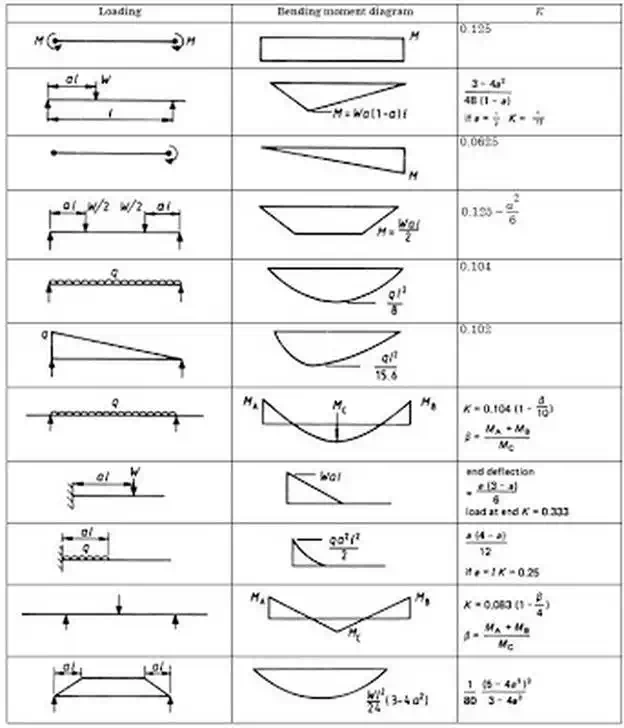

K = constant according to end supports and on

bending moment diagrams. K values are also shown in

the table below.