Reinforced Concrete - Slab Design

Types of suspended slabs that are considered (slabs which are supported by beams, columns, or walls)

● Solid slabs

○ These slabs are made out

of solid concrete with reinforcement that resist tension. Slabs can be in-situ

or profiled metal decking. The top reinforcement can be a steel mesh for the

use of fire resistance. The bottom reinforcement can be a metal decking for

tension reinforcement purposes.

● Ribbed slabs

○ These slabs can achieve the same structural strength than

solid slabs with less concrete required. Ribbed slabs can be series of in-situ

concrete ribs that are cast monolithically

with voids caused by removable formers. Ribbed slabs can also be a hollow slabs with permanent void formers.

● Flat slabs

○ These slabs with flat soffits do not require the support

of beams. Drops are often used to form a

thick stiffening part between the columns and the slab.

● Waffle slabs

○ These slabs are solid and flat with void formers in the

soffits. There are series of 1m wide concrete beams that can be designed for moment bending.

No slabs should be less than 125 mm thick due

to fire resistance requirements.

Two way spanning slabs can be 90% of thickness of one way

spanning slabs

1. Find w

w = 1.4DL + 1.6LL

2. Find the design moment and shear, M and V

Find M and V equations above (Refer to beam

calculations).

3. Design slab for flexure using One Way Slab

method

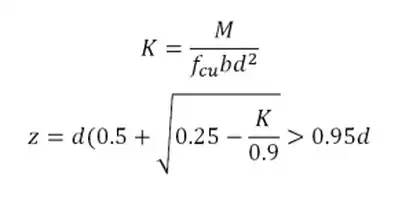

Find K and z

Find percentage of reinforcement in concrete

area (Ast/bd = %)

Reinforcement bars should

be designed to fulfill the minimum

area capacity and should be constructed in both directions in the slab. Steel

reinforcements help to resist cracking and to distribute concentrated loads

throughout the slab.

The maximum amount of reinforcement in

concrete members (beams, columns, or slabs) should not exceed 4%.

4. Find the number of reinforcement bars and

the size of the reinforcement bars, ____ T ______.

5. Find Asprov.

6. Design slab for shear.

Refer to here for rules for each constant in the concrete shear

stress equation below.

Minimum steel required = 0.13%

7. Check punching shear

Punching shear forces (shear forces around the

perimeter of columns) are usually the critical design case for flat slab

foundations. Effective shear is the shear force that takes moment forces caused

between the slab and the column and the shear force over the area supported by

the column.

● Effective shears

○ Internal columns -> Veff =

1.15V

○ Corner columns -> Veff =

1.25V

○ Edge columns -> Veff =

1.4V

Punching shear checks in flat slabs

● Shear stress, vo = Veff/ Uod < 0.8sqrt(Fcu) or 7 N/mm^2

○ Uo is the column perimeter that touches the slab

● Shear forces should be checked at

certain perimeters of slab enveloping the column. Shear forces should be checked starting at the first perimeter of

1.5d around the column face. Then, shear forces should

be checked subsequently at perimeters of 0.75d intervals.