Different grades of concrete :

Different grades of concrete has different Concrete Mix proportions which means different concrete mix ratios. As Per IS456:2000, the Concrete mix design has the following concrete mix proportions :-

Type of Concrete | Concrete Grade | Mix Ratio | Characteristic |

Ordinary concrete | M5 | 1:5:10 | 5 N/mm2 |

M7.5 | 1:4:8 | 7.5 N/mm2 | |

M10 | 1:3:6 | 10 N/mm2 | |

M15 | 1:2:4 | 15 N/mm2 | |

M20 | 1:1.5:3 | 20 N/mm2 | |

Standard Concrete | M25 | 1:1:2 | 25 N/mm2 |

M30 | Design Mix | 30 N/mm2 | |

M35 | Design Mix | 35 N/mm2 | |

M40 | Design Mix | 40 N/mm2 | |

M45 | Design Mix | 45 N/mm2 | |

M50 | Design Mix | 50 N/mm2 | |

High Strength | M55 | Design Mix | 55 N/mm2 |

M60 | Design Mix | 60 N/mm2 | |

M65 | Design Mix | 65 N/mm2 | |

M70 | Design Mix | 70 N/mm2 | |

|

|

|

|

Concrete Mixes are primarily divided into the two different types :

Nominal Mix is generally adopted for small scale constructions. In this type of mix, the mix ratios and concrete constituent proportions are prefixed and specified. Eg: M20(1:1.5:3); the quantity of cement, sand and aggregate is batched in volume as per the fixed ratio 1:1.5:3. From the above table till M25 grade, the concrete proportions are called as Nominal mix concrete.

Design mix concrete is adopted for high rise constructions. In this type of mix, the mix ratios are decided by an Engineer after analysing the properties of individual ingredients of concrete. Like, cement is tested for Fineness modulus and Specific gravity of cement in the lab while deciding the Design mix ratio. There is No Pre-fixed ratio, and ingredients are are batched in weight. From the above table, concrete grades more than M25 falls in Design mix.

In Simple, Design Mix refers to the ratios which are decided by the designer.

To calculate the individual quantities of cement, sand and aggregate required for 1m3 assume a nominal mix grade of concrete such as M20. You can use same method to calculate any grade of concrete.

Now let us consider M20 grade concrete;

As per IS456:2000, M20 Grade concrete proportion is = 1 : 1.5 : 3

We have to add all the volume to know the total volume = 1 + 1.5 + 3 = 5.5

As we know that during concreting when we place wet concrete, it gets harden after certain standard time. Considering the same it had be decided upon by Civil design Engineers to take a factor of safety ranging from 1.54 to 1.57 to counter that shrinkage.

i.e volume of dry Concrete = 1.54 to 1.57 times Volume of wet concrete

I am Assuming 1.57 as factor of safety

So total volume of concrete required is 1.57 m3

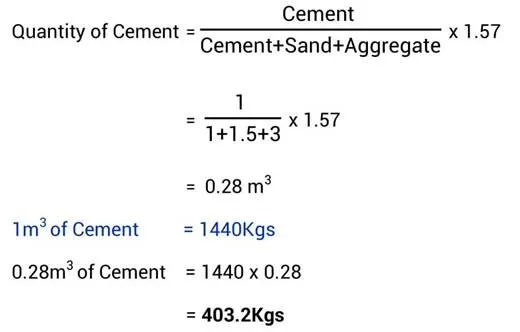

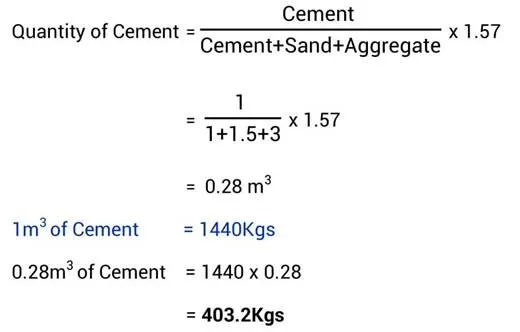

To calculate the Quantity of Cement in Concrete the following formula is used.

Volume of Cement

= Cement⁄Cement+Sand+Aggregate x 1.57

For 1m3 of Concrete = 403.2Kgs of Cement is required.

No. of Cement Bags required for 1m3 of Concrete = 403/50 = 8.06 ~ 8 bags

Hence we require 8 bags of cement for 1m3 of concrete.