Long-span beams

Design of long span beams

The use of long span beams results in a range of benefits, including flexible, column-free internal spaces, reduced foundation costs, and reduced steel erection times. Many long span solutions are also well adapted to facilitate the integration of services without increasing the overall floor depth.

The design of long span steel and (steel-concrete) composite beams is generally carried out in accordance with BS 5950[1], BS EN 1993[2] or BS EN 1994[3]. For some types of beam this codified guidance is complemented by specific design guidance, such as that on the design of beams with large web openings (see SCI P355 ), or manufacturers' information. Such specific guidance is normally based on extensive testing of a given product, and often presented in the form of design software.

Long span beam options

The solutions described below are presented in order of increasing spanning ability, with some overlap between options. The aim is to present a wide range of solutions. By far the most common types of beam used today are plate girders, and beams with web openings (be they cellular , fabricated, or rolled sections). Many solutions exploit the benefits of composite construction , which offers considerable strength and stiffness increases over a bare steel alternative.

Parallel beam approach

Parallel beam approach

The parallel beam approach is effective for spans up to around 14 m. Floor grids comprise two layers of fully continuous beams running in orthogonal directions. Services running in either direction can be integrated within these two layers, so that services passing in any direction can be accommodated within the structural floor depth. A further benefit is that, being fully continuous, the depth of the beams themselves is reduced without incurring the expense and complexity of rigid, full strength connections .

The figure on the left shows a composite floor using the parallel beam approach. Specific guidance on the design of this form of construction is given in SCI P074 . This is based on BS 5950 but the principles may be equally applied to a Eurocode design.

Composite beams with web openings

Service integration with cellular beams

Web openings are typically formed in beams to allow services to pass through the beam. This enables the structural and service zones to occupy the same space, thereby reducing the effective overall depth of floor construction for a given spanning capability. Openings may also be formed for aesthetic reasons, for instance with cambered beams used to support a roof. Composite beams with web openings have been shown to be a cost effective solution for spans in the range 10 to 16 m.

A particular type of composite beam with web openings is the so-called cellular beam, which is formed in a specific way and therefore described separately below . The alternative way of forming the web openings is simply to cut them into the plate used to form the web of a plate girder, or into the web of a rolled section. The most appropriate solution to adopt depends on the size, shape and regularity of the openings, or more commercial drivers such as the method used by a preferred supplier. Beams with web openings present no disadvantages in terms of erection and familiarity as they are much the same as a 'standard' solid web beam.

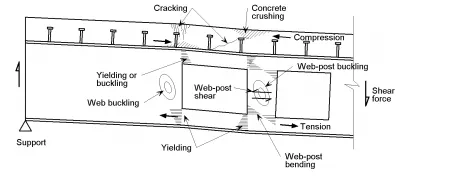

The design of beams with web openings must recognise the fact that the openings introduce a number of potential failure modes not found in solid web beams. Around the openings the beam behaves as a Vierendeel girder, and web post buckling may govern design (the web post is the section of web found between two adjacent openings, as shown in the figure below). Large openings may require stiffening to avoid instability (buckling) of the web posts.

Modes of failure at large closely spaced openings

Composite beam with stiffened web openings

The figure above right shows a composite plate girder with stiffened web openings. Dedicated design guidance (SCI P355) and software from specialist manufacturers is available, based on extensive test programmes that have included fire testing.

Cellular composite beams

Cellular beams and services

Cellular beams are a form of beam with multiple regular web openings , formed by splitting two rolled sections longitudinally, to form two Tee sections. The two Tees, which may not come from the same donor section (as discussed below) are then welded together to form an I-section with web openings which have a characteristic shape (normally, but not necessarily, circular). The process used to form cellular beams enables the bottom half of the final beam to be formed from a heavier donor section than the top half - in other words the bottom flange can be significantly bigger than the top flange. This makes sense when, as is often the case, the beams are to act compositely and therefore a concrete flange effectively replaces the upper steel flange in the final state (the upper steel flange only needs to be big enough to meet construction needs and serve as a platform for the shear studs).

BS EN 1994 provides design rules to cover beams with an asymmetry (area of the bottom steel flange divided by that of the upper flange) of up to three. The greater the asymmetry the more onerous the requirements for minimum degree of shear connection , which must be observed to prevent excessive slip between the steel and concrete elements.

Although cellular beams have regular openings, some of these may be infilled, and/or stiffening added to accommodate local features such as incoming beams or heavy point loads. Double (oval) openings may also be included to facilitate the passage of larger service ducts. Dedicated design guidance (SCI P355 ) and software is available from specialist manufacturers, based on extensive test programmes that have included fire testing. The figure below shows a cellular beam, with regular circular web openings, and services sharing a common floor zone.