How Fire Resistance Ratings are Measured

Will a four-hour fire wall really resist the spread of heat and flames for 240 minutes? Will a twohour floor/ceiling assembly truly prevent vertical fire spread for 120 minutes while a highrise building is evacuated?

The answer is definitely “maybe” and depends upon the actual fire exposure conditions.

In order to obtain an hourly fire-resistance rating, sample fire assemblies must undergo rigorous testing under controlled laboratory conditions. These conditions may not match real world environments found in buildings.

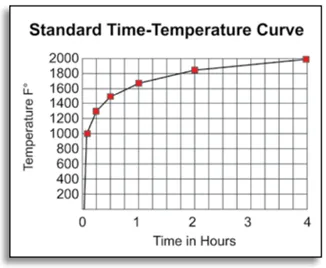

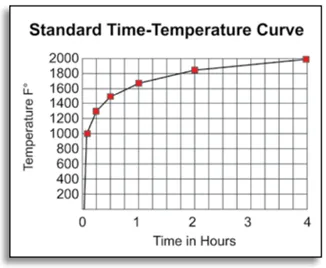

To establish their hourly ratings, fire assemblies are installed in a temperature-controlled propane gas-fired furnace, and the temperature is increased over a prescribed period of time in accordance with the criteria established in the American Society for Testing and Materials standard E119 “Test Methods for Fire Tests of Building Construction and Materials.” This time-temperature relationship is called the Standard Time-Temperature Curve.

The Standard Time-Temperature Curve is used to evaluate fire resistance ratings of various assemblies.

If the assembly “survives* ” the fire test for a specific period of time, the assembly is recognized as meeting that hourly rating. For example, if a fire barrier assembly survives the increasing temperature fire test for 180 minutes, it is considered to be equivalent to a “three-hour assembly.” That assembly could be installed in those locations where the model building codes require the installation of a three-hour fire barrier.

Since a rated assembly may not provide the fully hourly rating under real fire conditions, hourly ratings should be used for comparisons and not guarantees. A three-hour assembly should survive longer than either a two- or one-hour assembly, but since fuel and ventilation in buildings likely does not match the controlled laboratory conditions, one should not expect the assembly to last the full three hours in an uncontrolled fire.